Color printing ink solvent oil and preparation method thereof

A technology of color ink and production method, applied in the field of printing ink solvent, can solve the problems of unbalanced solvent oil to resin solubility and release performance, poor water resistance of solvent oil, poor rheology of solvent oil, etc., so as to prevent flying ink. phenomenon, reduce rubbing accidents, and the effect of color saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

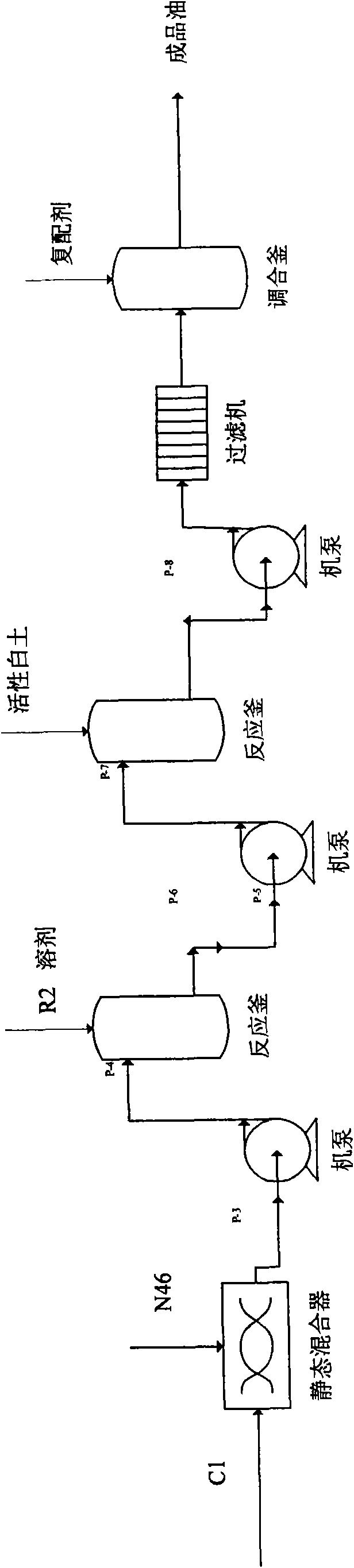

[0028] Such as figure 1 process figure 1 , Technological process description: base oil → solvent refining → white clay decolorization and refining → compound agent blending → refined oil.

[0029] 1. Production process: Color ink solvent oil is made of naphthenic crude oil fractions, special solvent dearomatization process, clay decolorization and refining process to produce base oil, and then blended with unique compound additives. The specific operation steps are as follows:

[0030] Solvent Refining:

[0031] 1) The naphthenic crude fraction C1 and N46 base oils are separated and fused by a static mixer according to the ratio of 7:3, poured into the reaction kettle, heated by the built-in heating coil, and the temperature is controlled at 30-40 ℃.

[0032] 2) Measure a certain amount of R2 solvent (base oil: R2=98.5:1.5), and slowly add the R2 solvent into the reaction kettle. During the addition, first start the agitator and control a certain stirring speed.

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com