Compound SBS modified asphalt and preparation method thereof

A compound modified asphalt and asphalt pump technology, applied in building components, building thermal insulation materials, construction and other directions, can solve the problems of pollution, polluted air, tire corrosion resistance affecting the environment, etc., to enhance construction workability, improve product quality quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

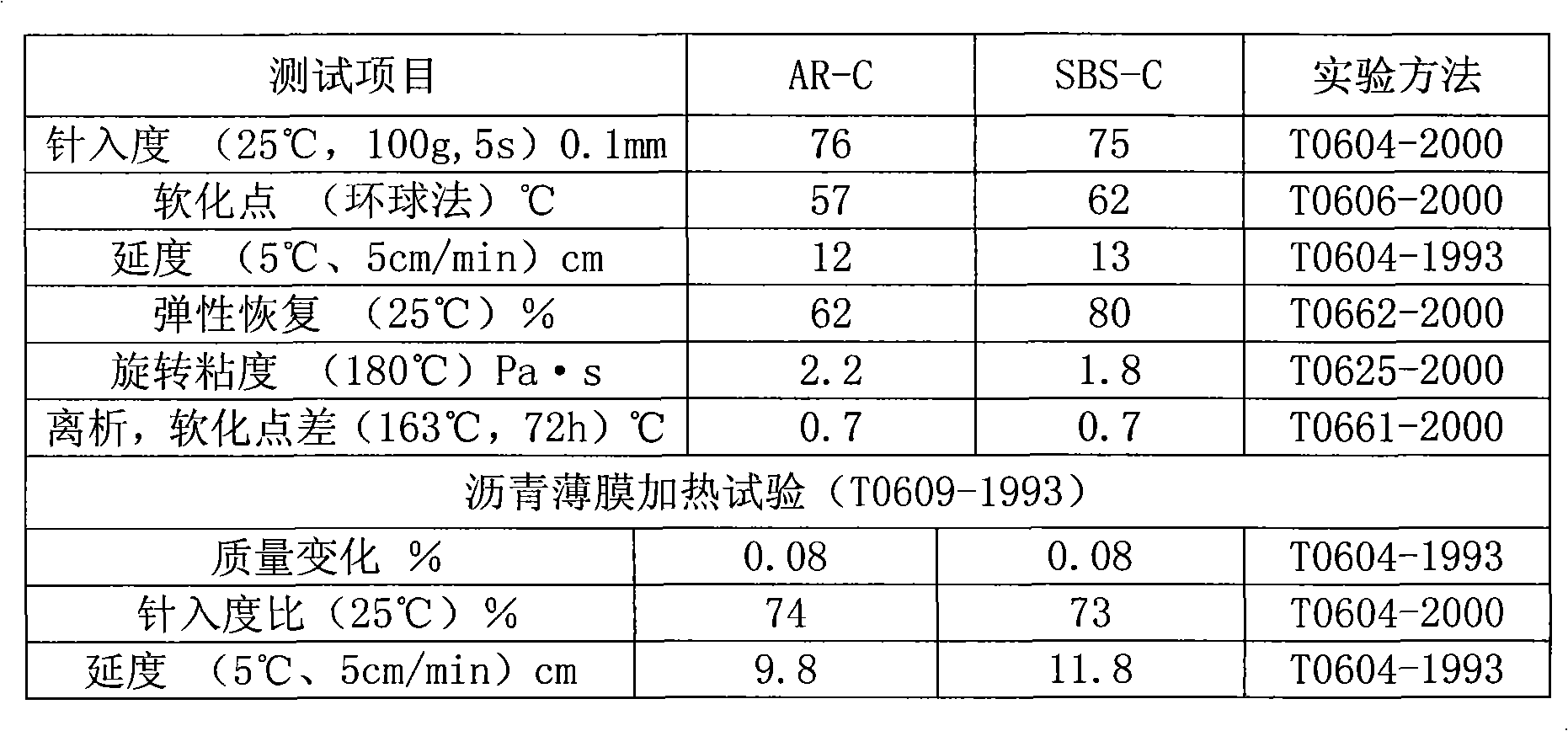

Examples

Embodiment Construction

[0021] Preparation Examples:

[0022] Petroleum asphalt is sent to a low-speed pre-shear mixer through an asphalt pump, a mass flow meter, and a rapid heating heat exchange system to 170-180°C; metered addition of SBS polymer, rubber powder, coal tar, and dimethylamino Pyridine and butaurium glue, complete the full swelling of petroleum asphalt on SBS polymer in the mixer; after the pre-mixing and swelling stages, the mixture enters the colloid mill through the asphalt pump and fully grinds to obtain the required dispersion and mixing state; The fully ground mixture is pumped into the development tank through an asphalt pump, added with dibutyltin dibenzoate as a stabilizer, and developed for 1 hour at a temperature of 180°C under low-speed stirring to become a qualified SBS composite modified asphalt product. The ratio is: 42.3% of petroleum asphalt; 35% of rubber powder; 15% of coal tar; 2% of SBS polymer; 3% of dimethylaminopyridine (catalyst);

[0023] Among them, SBS is:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com