Production method of sunflower seed oil and edible sunflower seed oil

A production method and technology for sunflower oil, which are applied in the production and application of edible oil/fat, fat oil/fat, etc., can solve the problems of high wax content and low oil yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

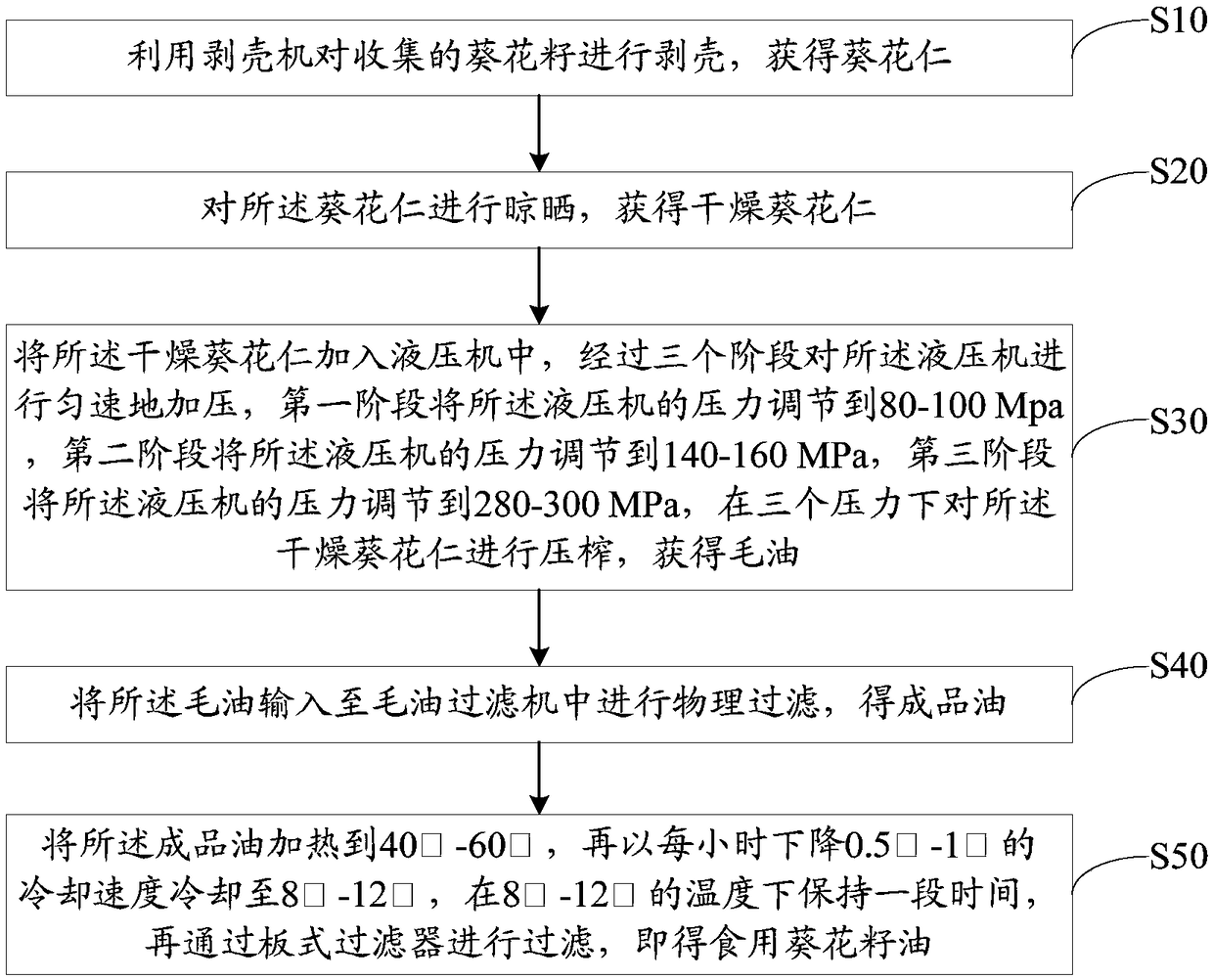

[0048] (1) Utilize the shelling machine to shell the collected sunflower seeds to obtain sunflower kernels;

[0049] (2) drying the sunflower kernels for 40 minutes to obtain dried sunflower kernels;

[0050] (3) Press the dried sunflower kernels into sunflower kernel cakes of about 5kg, put 20 pieces of sunflower kernel cakes into the hydraulic press every time, and pressurize the hydraulic press at a uniform speed through three stages. In the first stage, the The pressure of the hydraulic press is adjusted to 80MPa and kept for 30min. In the second stage, the pressure of the hydraulic press is adjusted to 140MPa and kept for 80min. In the third stage, the pressure of the hydraulic press is adjusted to 280MPa and kept for 40min. Dried sunflower kernels are pressed to obtain crude oil;

[0051] (4) inputting the crude oil into a crude oil filter for physical filtration to obtain refined oil;

[0052] (5) Heat the finished oil to 50°C, then cool down to 10°C at a cooling rate...

Embodiment 2

[0054] (1) Utilize the shelling machine to shell the collected sunflower seeds to obtain sunflower kernels;

[0055] (2) drying the sunflower kernels for 40 minutes to obtain dried sunflower kernels;

[0056] (3) Press the dried sunflower kernels into sunflower kernel cakes of about 5kg, put 20 pieces of sunflower kernel cakes into the hydraulic press every time, and pressurize the hydraulic press at a uniform speed through three stages. In the first stage, the The pressure of the hydraulic press is adjusted to 90MPa and kept for 30min. In the second stage, the pressure of the hydraulic press is adjusted to 150MPa and kept for 80min. In the third stage, the pressure of the hydraulic press is adjusted to 290MPa and kept for 40min. Dried sunflower kernels are pressed to obtain crude oil;

[0057] (4) inputting the crude oil into a crude oil filter for physical filtration to obtain refined oil;

[0058] (5) Heat the finished oil to 50°C, then cool down to 10°C at a cooling rate...

Embodiment 3

[0060] (1) Utilize the shelling machine to shell the collected sunflower seeds to obtain sunflower kernels;

[0061] (2) drying the sunflower kernels for 40 minutes to obtain dried sunflower kernels;

[0062] (3) Press the dried sunflower kernels into sunflower kernel cakes of about 5kg, put 20 pieces of sunflower kernel cakes into the hydraulic press every time, and pressurize the hydraulic press at a uniform speed through three stages. In the first stage, the Adjust the pressure of the hydraulic press to 100MPa and keep it for 30min. In the second stage, adjust the pressure of the hydraulic press to 160MPa and keep it for 80min. In the third stage, adjust the pressure of the hydraulic press to 300MPa and keep it for 40min. Dried sunflower kernels are pressed to obtain crude oil;

[0063] (4) inputting the crude oil into a crude oil filter for physical filtration to obtain refined oil;

[0064] (5) Heat the finished oil to 50°C, then cool down to 10°C at a cooling rate of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com