A kind of phosphorus-containing polymer hydrogel and its preparation method and application

A technology of hydrogels and polymers, applied in the directions of alkali metal compounds, chemical instruments and methods, water pollutants, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In a 500mL round-bottom three-necked flask equipped with a thermometer, dropping funnel and mechanical stirring, add 75 parts by mass of vinylphosphonic acid and 25 parts by mass of methacrylic acid, add 30 wt% polyethylene glycol diacrylate cross The joint agent and 0.01wt% polyvinyl alcohol were fully dissolved in 200 mL of deionized water at 65°C under constant temperature and vigorous mechanical stirring and mixed uniformly. The initiator benzoyl peroxide was dissolved in an appropriate amount of toluene to prepare an initiator solution with a concentration of 0.01wt%. After the polymerization started, the initiator solution was added dropwise to the polymerization reaction system, and the crosslinking was maintained at a constant temperature of 65 °C. Aggregate for 2h. The synthesized gel microspheres were washed repeatedly in secondary deionized water and dried under vacuum at 50 °C until the quality remained unchanged.

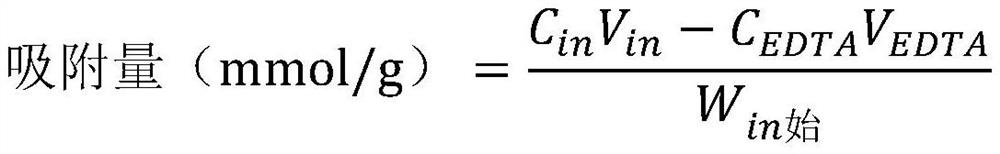

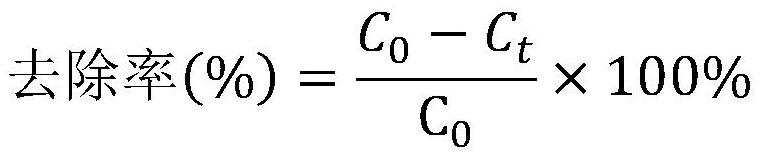

[0036] The experimental steps for the adsor...

Embodiment 2

[0040] Add 120 parts by mass of vinylphosphonic acid and 186 parts by mass of acrylic acid to a 500 mL three-necked flask, then add 3 parts by mass of N-maleamide chitosan, and finally add 200 mL of deionized water, stir well to make the three The substances were fully mixed and uniform, nitrogen was introduced into the polymerization device and kept for 30 minutes, and the temperature was raised to 80°C and then kept at a constant temperature. 1.6 parts by mass of the initiator 2'2-azobisisobutylamidine dihydrochloride was dissolved in an appropriate amount of deionized water, and the initiator was added dropwise to the polymerization system at a constant temperature of 80°C. After 0.5 h of cross-linking polymerization, the prepared hydrogel product was taken out and soaked in deionized water for 48 h to remove the monomers that did not participate in the polymerization reaction in the hydrogel, and the deionized water was regularly replaced until the deionized water became ne...

Embodiment 3

[0045] Polyvinylphosphonic acid nanogel synthesis: 67 mL of vinylphosphonic acid was dispersed in 0.01 M 3000 mL of hexadecane together with 10 mol% ethylene glycol dimethacrylate (14.4 mL) relative to the total monomer amount in trimethylammonium bromide solution. The mixture was stirred using magnetic stirring for 3 minutes to obtain a clear isotropic solution, which was then placed in a temperature-controlled oil bath at 75°C. The stirring rate was adjusted to 600 rpm for 20 minutes to equilibrate the system temperature to 75°C, and polymerization was initiated by adding 100 mL of 0.01734 g / mL aqueous ammonium persulfate solution. Polymerization was carried out for 8 hours and the nanogels were purified by centrifugation at 11000 rpm for 20 minutes at 20°C, then the supernatant was removed and redispersed in deionized water and re-centrifuged at least 5 times. The product was dried overnight using a freeze dryer and stored in airtight vials for further use.

[0046] To de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com