Transparent and invisible RFID label material and preparation method

An RFID tag and invisible technology, applied in the field of RFID, can solve the problems of weak anti-bending ability, easy damage, loss of product authenticity and uniqueness of RFID tags, etc., achieve good anti-theft and anti-counterfeiting functions, reduce surface resistance, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

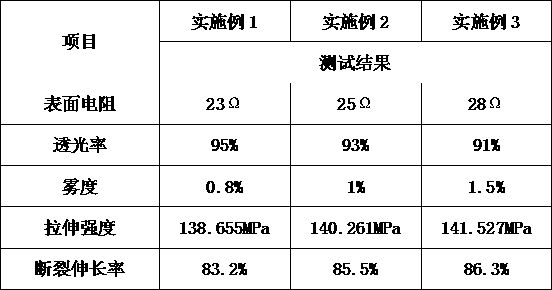

Embodiment 1

[0023] A kind of preparation of transparent invisible RFID tag material:

[0024] S1, take a PET film with a thickness of 0.01mm as the matrix film, lay it flat on the coating platform, and coat 0.1% nano-silver wire conductive silver paste on the matrix layer through a coating machine, the length and diameter of the nano-silver wire The ratio is 1000, the coating thickness is 30 μm, and the nano-silver wire conductive silver paste is cured at room temperature to obtain a conductive layer;

[0025] S2, preparation of conductive layer pattern: the conductive layer prepared in step S1 forms a conductive pattern by screen printing;

[0026] S3, preparation of the adhesive layer: the surface of the conductive layer prepared in step S2 is further coated with a UV-curable pressure-sensitive adhesive on the conductive layer, the coating thickness is 5 μm, and the thickness is 2 J / cm under the irradiation of a UV lamp. 2 The energy curing, that is, transparent invisible RFID label ma...

Embodiment 2

[0028] Preparation of a transparent invisible RFID label material:

[0029] S1, take a PE film with a thickness of 0.2mm as the matrix film, lay it flat on the coating platform, and coat 0.2% nano-silver wire and nano-silver particle conductive silver paste on the matrix layer through a coating machine, the nano-silver wire The ratio of length to diameter is 700, the coating thickness is 40 μm, and the conductive silver paste of nano-silver wire is cured at room temperature to obtain a conductive layer;

[0030] S2, preparation of conductive layer pattern: the conductive layer prepared in step S1 is mechanically embossed to form a conductive pattern;

[0031] S3, preparation of the adhesive layer: the surface of the conductive layer prepared in step S2 is further coated with a hot-melt adhesive on the conductive layer to a thickness of 8 μm, and cured at room temperature for 3 hours to obtain a transparent invisible RFID label material.

Embodiment 3

[0033] A kind of preparation of transparent invisible RFID tag material:

[0034] S1, take a PVC film with a thickness of 0.3mm as the matrix film, lay it flat on the coating platform, and coat 0.3% nano-silver wire conductive silver paste on the matrix layer through a coating machine, the length and diameter of the nano-silver wire The ratio is 500, the coating thickness is 50 μm, and the nano-silver wire conductive silver paste is cured at room temperature to obtain a conductive layer;

[0035] S2, preparation of conductive layer pattern: the conductive layer prepared in step S1 is mechanically embossed to form a conductive pattern;

[0036] S3, preparation of the adhesive layer: the surface of the conductive layer prepared in step S2 is further coated with a solvent-based resin adhesive on the conductive layer to a thickness of 10 μm, and cured at room temperature for 3 hours to obtain a transparent invisible RFID label material.

[0037] The production of conductive lines...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com