Perovskite quantum dot glaze, photovoltaic glass and preparation method thereof, and photovoltaic module

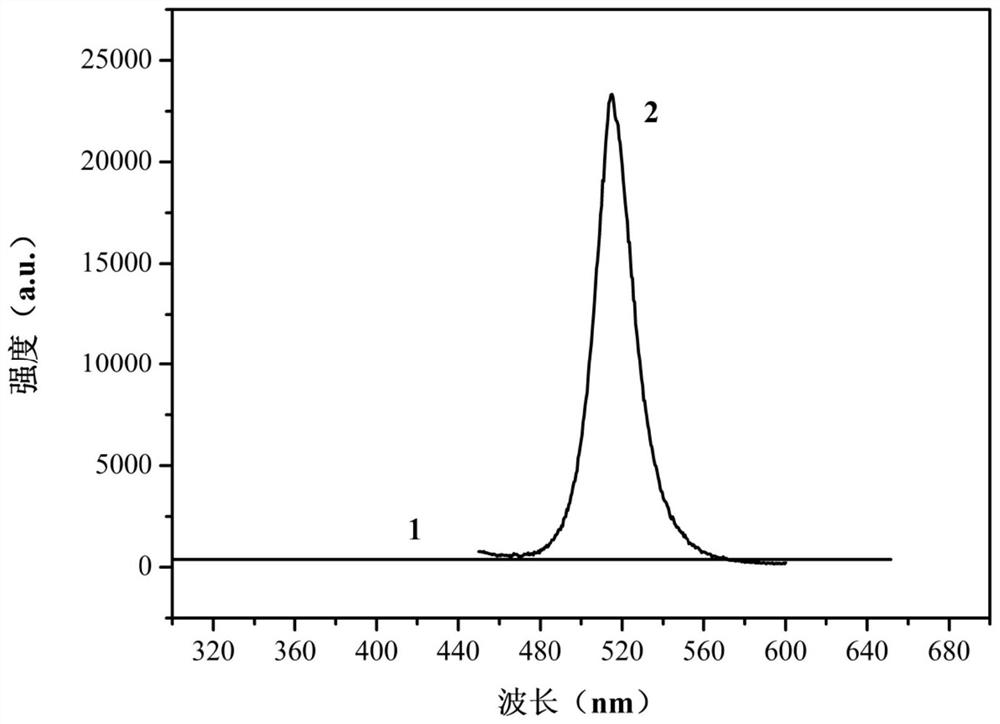

A photovoltaic glass and quantum dot technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as low power generation efficiency and narrow light wavelength range, and achieve improved light utilization, high utilization, high absorption and The effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Transparent glaze (according to 100 parts by weight), its composition and mass ratio are: 58 parts of frit, 10 parts of feldspar, 12 parts of quartz, 8 parts of dolomite, 6 parts of borax, 2 parts of calcite, 2 parts of boric acid, 1 part of zinc oxide, 1 part of glass powder; wherein, frit (according to 100 parts by weight), its composition and mass ratio are: SiO 2 51 copies, B 2 o 3 18 copies, K 2 O 14 parts, Al 2 o 3 6 copies, Li 2 5 parts of O, 1 part of ZnO, 5 parts of SrO, the incipient melting temperature of the frit is 580°C;

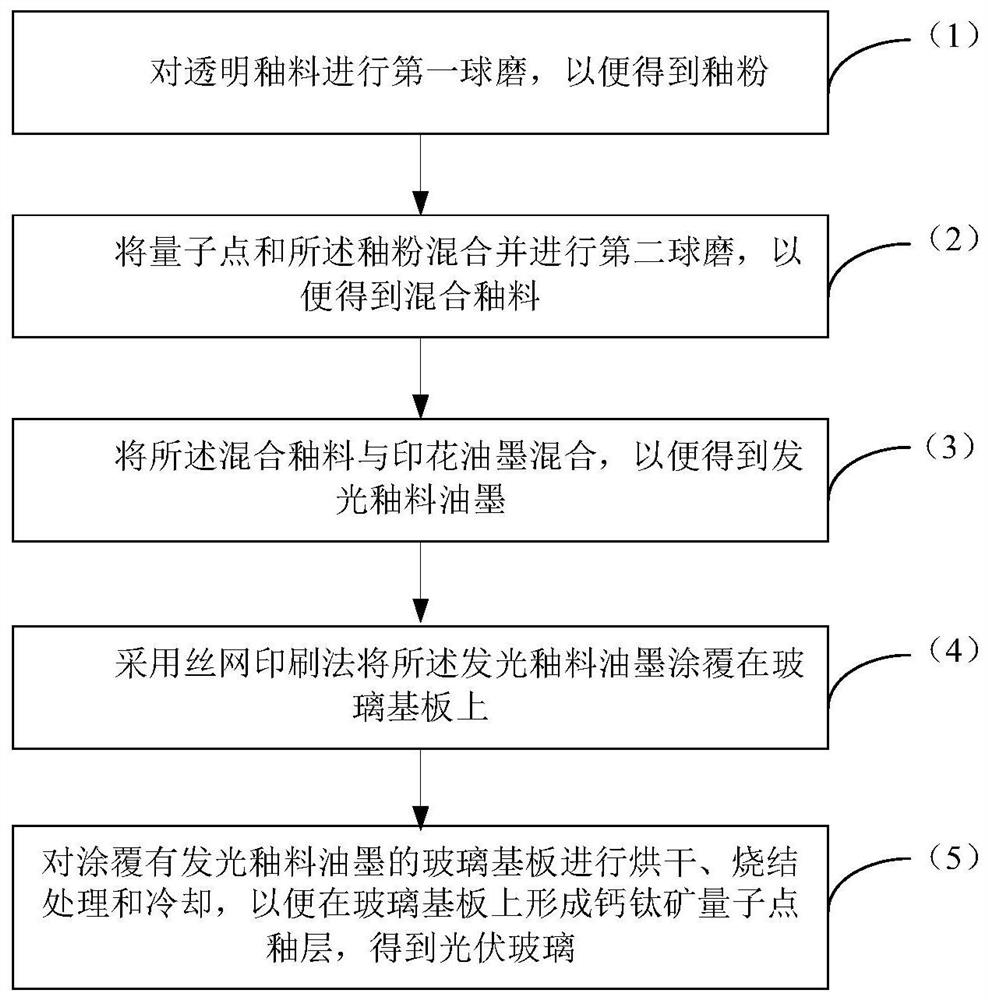

[0069] The preparation method of the photovoltaic glass comprises the following steps:

[0070] (1) Put the transparent glaze into an ultra-fine ball mill for the first ball mill to obtain glaze powder. The speed of the ball mill is 350r / min, and the ball mill is 48h. Material: ball: water = 1: 1.8: 0.5;

[0071] (2) CsPbBr with core-shell structure 3 Quantum dot powder and glaze powder are added into the ball mill tank accord...

Embodiment 2

[0077] Transparent glaze (according to 100 parts by weight), its composition and mass ratio are: 65 parts of frit, 13 parts of feldspar, 9 parts of quartz, 4 parts of dolomite, 3 parts of borax, 2 parts of calcite, 1 part of boric acid, 1 part of zinc oxide, 2 parts of glass powder; wherein, frit (according to 100 parts by weight), its composition and mass ratio are: SiO 2 55 copies, B 2 o 3 16 copies, K 2 O 12 parts, Al 2 o 3 5 copies, Li 2 6 parts of O, 2 parts of ZnO, 4 parts of SrO, the incipient melting temperature of the frit is 530°C;

[0078] The preparation method of the blue photovoltaic glass comprises the following steps:

[0079] (1) Put the transparent glaze into an ultra-fine ball mill for the first ball mill to obtain glaze powder. The speed of the ball mill is 350r / min, and the ball mill is 48h. Material: ball: water = 1:2:0.6;

[0080] (2) Put the blue colorant and glaze powder into the ball mill tank according to the mass ratio of 1:12, mix and per...

Embodiment 3

[0086] The difference from Example 2 is: change the blue color material in step (2) to yellow color material, add the color material and glaze powder to the ball mill tank according to the mass ratio of 1:10, mix and perform the third ball mill, and adjust the mixture The mass ratio of water and water is 1:0.62, continue ball milling and mixing for 40 minutes to obtain colored glaze powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com