Insulation system and working method for greenhouse

A heat preservation system and greenhouse technology, applied in the field of agricultural greenhouses, can solve the problems of occupying the inner space of the greenhouse, inconvenient installation and use, and unfavorable maintenance in the later period, and achieve the effects of scientific and reasonable overall design, prolonging the service life and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

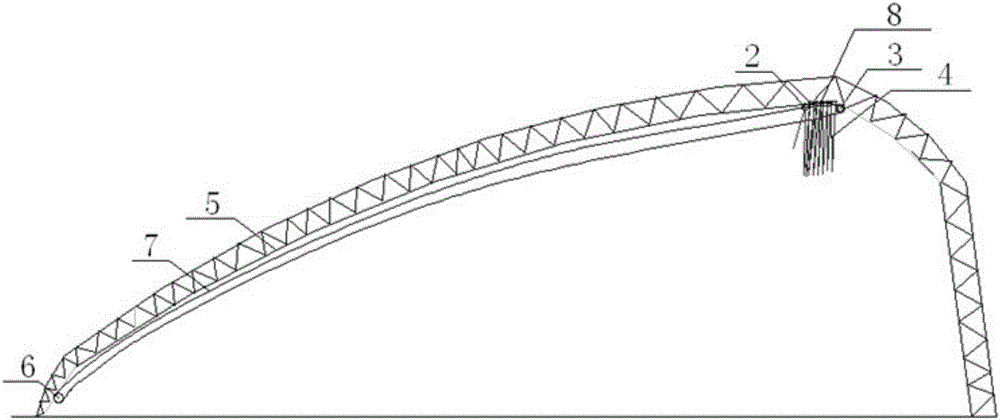

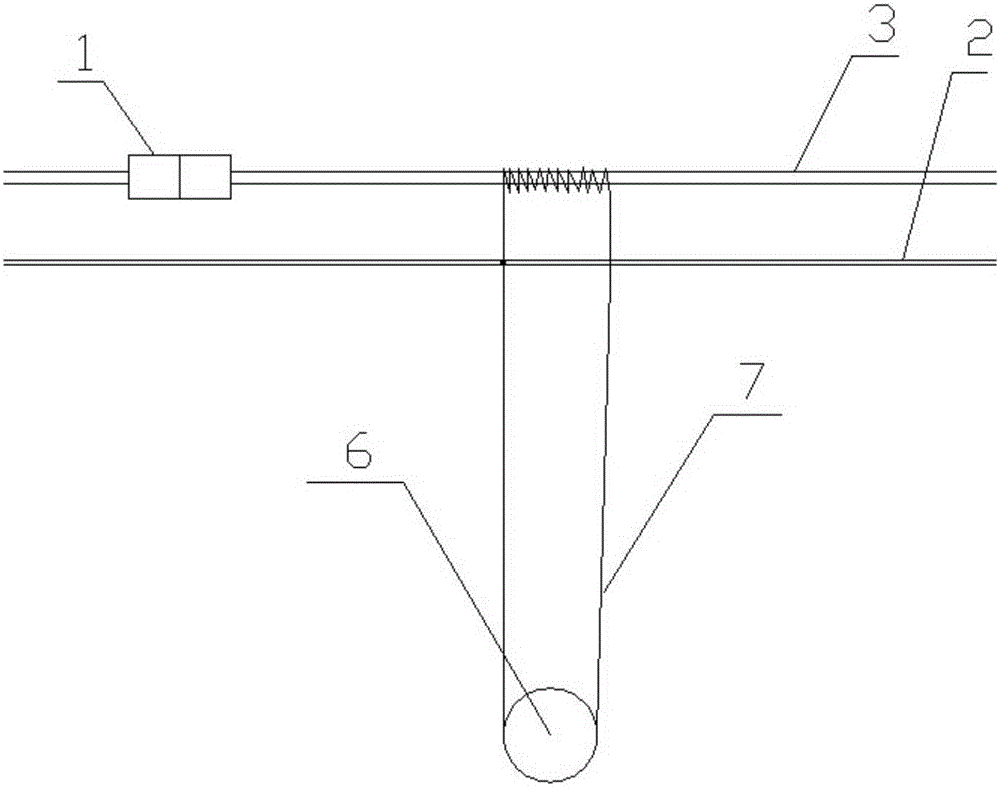

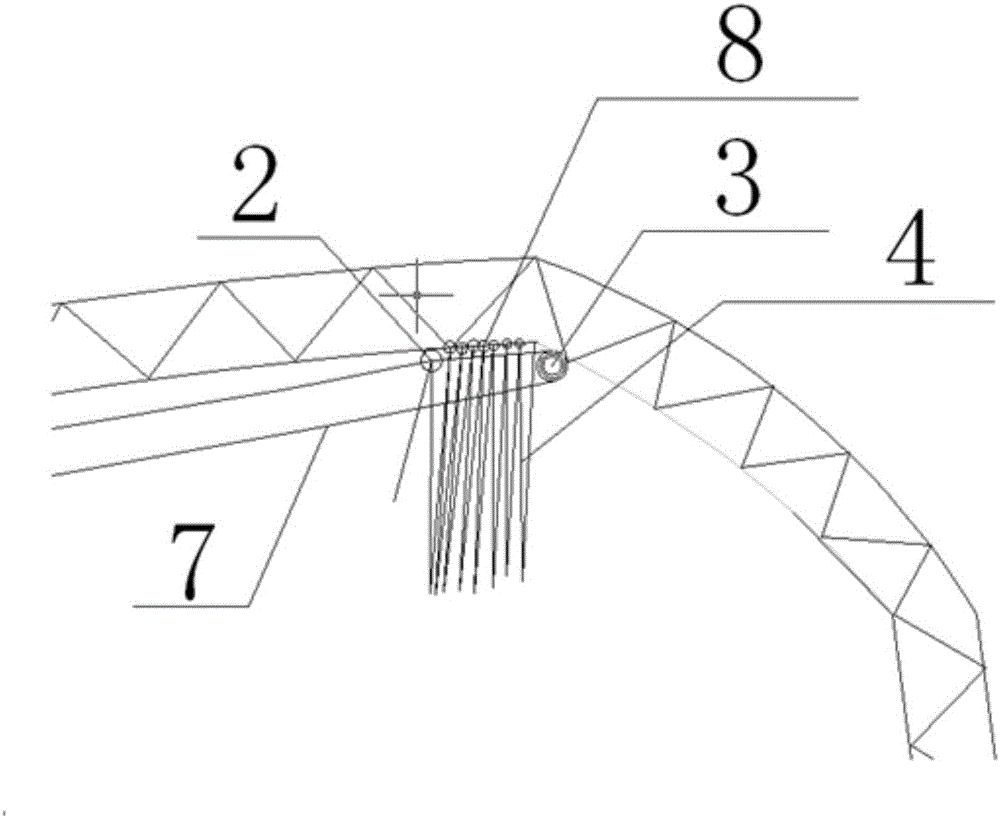

[0050] Such as figure 1 with figure 2 As shown, a new type of heat preservation greenhouse provided by the present invention includes a greenhouse body, and a greenhouse steel frame track, a thermal insulation quilt 4 and an information control device are arranged inside the greenhouse body;

[0051] A transmission shaft 3 is arranged on the top of the steel frame track in the greenhouse, a fixed pulley 6 is arranged on the bottom end of the steel frame track in the greenhouse, and a plurality of moving pulleys 8 are arranged on the steel frame track in the greenhouse. It is fixedly connected with the heat preservation quilt 4, and a cross bar 2 is set through the end of the heat preservation quilt 4; a transmission rope 7 is arranged under the steel frame track of the greenhouse, and one end of the transmission rope 7 is fixedly connected with the cross bar 2, The other end of the transmission rope 7 bypasses the fixed pulley 6 and is fixedly connected to the crossbar 2 aft...

Embodiment 2

[0060] The present invention provides a new type of thermal insulation greenhouse, the structure of which is as described in Example 1. The difference is that the steel frame rails of the greenhouse include 66 parallel rails 5, and the distance between adjacent rails 5 is 1.5 meters. 10 movable pulleys 8 of the same specification are all set on each track 5 . The bottom of each track 5 can be provided with two independent transmission ropes 7, and one end of one transmission rope is fixedly connected on the cross bar 2, and the other end goes around the fixed pulley 6 and winds the transmission shaft 7 counterclockwise and is fixedly arranged on the transmission shaft 7. One end of the other transmission rope is fixedly connected to the cross bar 2, and the other end is wound clockwise around the transmission shaft 7 and then fixedly arranged on the transmission shaft 7.

Embodiment 3

[0062] The working method of the thermal insulation system in a greenhouse provided by the present invention comprises the following steps,

[0063] (1) Set the five temperature sensors at the five orientations of east, west, south, north and middle in the greenhouse, and all temperature sensors are connected to the air pressure controller;

[0064] (2) Turn on the air switch, start the internal heat preservation system, the temperature sensors at five locations will transmit the temperature values collected in real time to the air pressure controller, and the air pressure controller will analyze and process the received temperature values to calculate the greenhouse The average temperature value within;

[0065] (3) judge the average temperature value obtained in step (2) and the threshold value preset by the air pressure controller, when the average temperature value in the greenhouse is greater than the threshold value, the air pressure controller issues an opening comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com