A kind of plant polysaccharide aerogel air purification material and preparation method

An air purification material and plant polysaccharide technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of limited application of aerogel, limited resources, difficult degradation, etc., achieve excellent adsorption performance, and reduce raw material costs. , the effect of enriching the network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

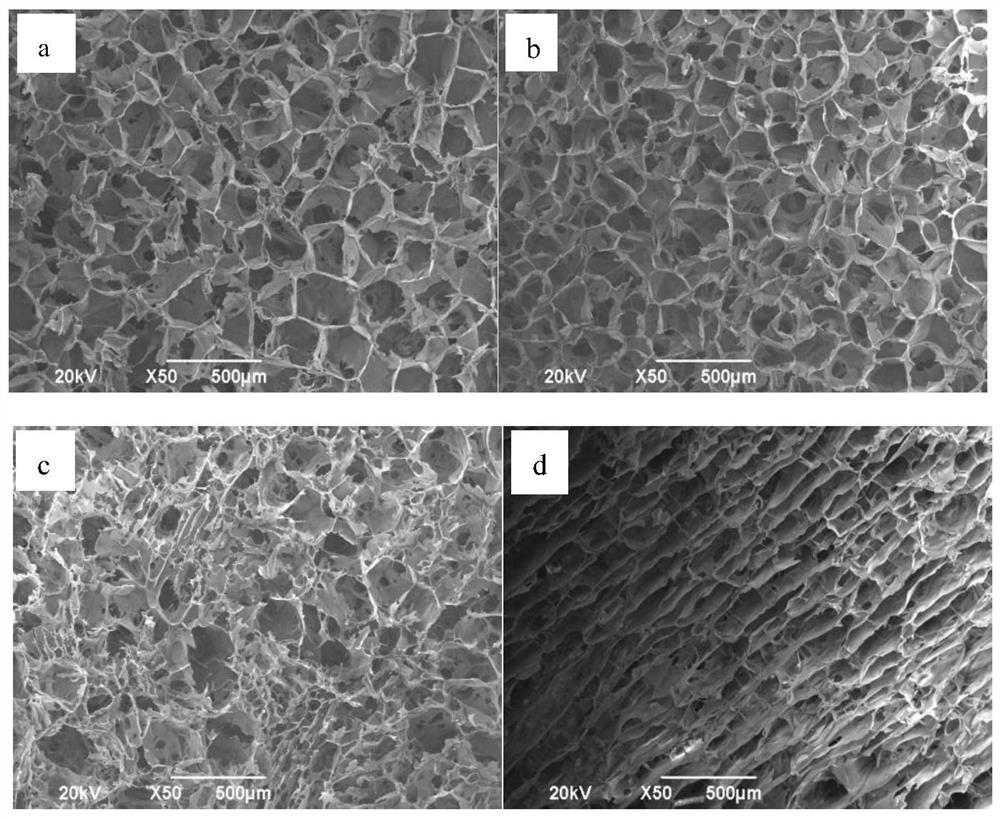

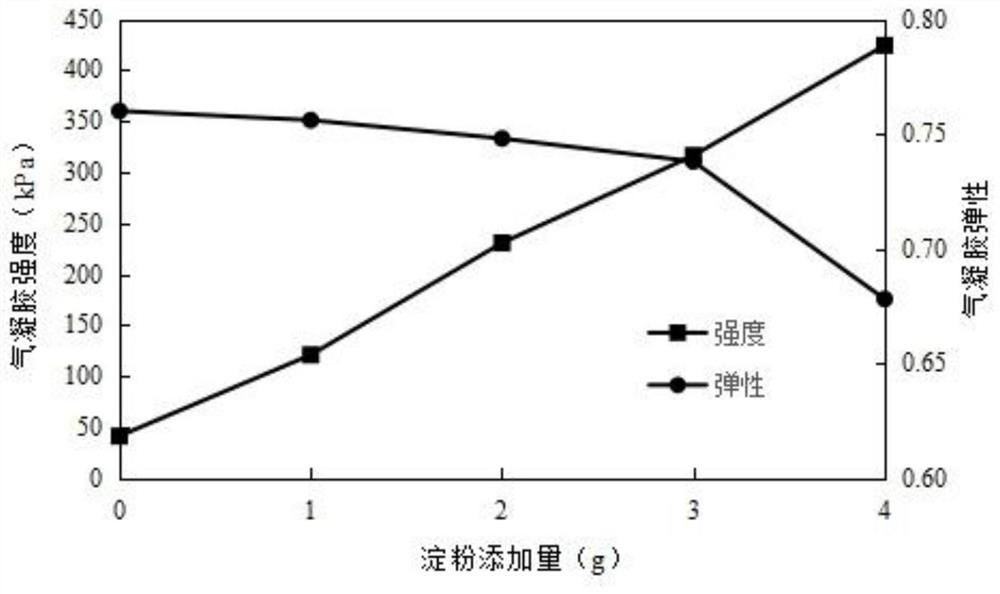

Image

Examples

Embodiment 1

[0054] A preparation method of plant polysaccharide airgel air-purifying material, comprising the following steps:

[0055] (1) Sol-gel ingredients

[0056] Mix 1g of starch, 3g of gelatin and 93.9g of water, stir for 20min at a temperature of 60°C, and rotate at a speed of 500rpm; then add 1g of konjac glucomannan, 1g of rice straw powder and 0.1g of nano-calcium carbonate, and stir at a temperature of 60°C Under the condition of a speed of 800 rpm, after stirring for 60 minutes, vacuum degassing treatment was performed to obtain a mixed sol.

[0057] (2) Film injection

[0058] The mixed sol sample was poured into a mold at 60°C for molding with a molding thickness of 2mm.

[0059] (3) Aging treatment

[0060] Place the mold filled with the mixed sol in an environment of 30° C. for aging for 2 hours.

[0061] (4) Pre-freezing

[0062] Place the semi-finished product in step (3) in a freezing environment for pre-freezing, the pre-freezing temperature is -10°C, and the ti...

Embodiment 2

[0068] A preparation method of plant polysaccharide airgel air-purifying material, comprising the following steps:

[0069] (1) Sol-gel ingredients

[0070] Mix 2g of starch, 2g of gelatin and 92.3g of water, stir at 80°C for 20min, and rotate at 600rpm; then add 1.5g of konjac glucomannan, 2g of wheat straw powder and 0.2g of nano-calcium carbonate, at a temperature of 80°C, Under the condition of a stirring speed of 900 rpm, after stirring for 90 min, degassing treatment was performed to obtain a mixed sol.

[0071] (2) Film injection

[0072] The mixed sol sample was poured into a mold at 80°C for molding, and the molding thickness was 5 mm.

[0073] (3) Aging treatment

[0074] The mold filled with the mixed sol was placed in an environment of 20°C for aging, and the aging time was 6 hours.

[0075] (4) Pre-freezing

[0076] Place the semi-finished product in step (3) in a freezing environment for pre-freezing, the pre-freezing temperature is -15°C, and the time is 10...

Embodiment 3

[0083] A preparation method of plant polysaccharide airgel air-purifying material, comprising the following steps:

[0084] (1) Sol-gel ingredients

[0085] Mix 3g starch, 2g gelatin and 90.7g water, stir at 90°C for 20min, and rotate at 600rpm; then add 1g konjac glucomannan, 3g corn straw powder and 0.3g nano-silicon dioxide to it, at a temperature of 90°C, Under the condition of a stirring speed of 1000 rpm, after stirring for 90 min, vacuum degassing treatment was performed to obtain a mixed sol.

[0086] (2) Film injection

[0087] Pour the mixed sol into a mold at 90°C for molding, and the molding thickness is 5 mm.

[0088] (3) Aging treatment

[0089] The mold filled with the mixed sol was placed in an environment of 15°C for aging, and the aging time was 10h.

[0090] (4) Pre-freezing

[0091] Place the semi-finished product in step (3) in a freezing environment for pre-freezing, the pre-freezing temperature is -20° C., and the time is 10 h.

[0092] (5) freeze-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com