Roll-position-controllable polypropylene super hydrophobic film or block material and their preparing method

A polypropylene film and rolling angle technology, applied in the field of super-hydrophobic polypropylene film or block and its preparation, can solve the problems of high raw material price, difficult application, high price, etc., and achieve simple equipment, low cost and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] After the isotactic polypropylene pellets are cleaned, add decahydronaphthalene to prepare a solution with a concentration of 3 wt%, place it in a sealed glass tube, heat it to about 160°C, and stir it magnetically until it completely dissolves into a transparent and uniform solution. In order to accurately study the shear dependence of contact angle and rolling angle, the solution was introduced into the quartz shear cell of CSS-450 high temperature shear heat station (Linkam Scientific Instruments Ltd., UK), so that the shear and temperature conditions can be precisely controlled . The quartz parallel plate is set up, the plate spacing is 30 microns, the solution is placed on the parallel plate, and the temperature is raised to 110°C; the solution is cooled from 110°C to 40°C at a rate of 15°C / min, and then the application rate is 5s -1 The shearing time is 20s, and it is kept at 40°C until the structure is completely formed. Under such conditions, the polypropylene p...

Embodiment 2

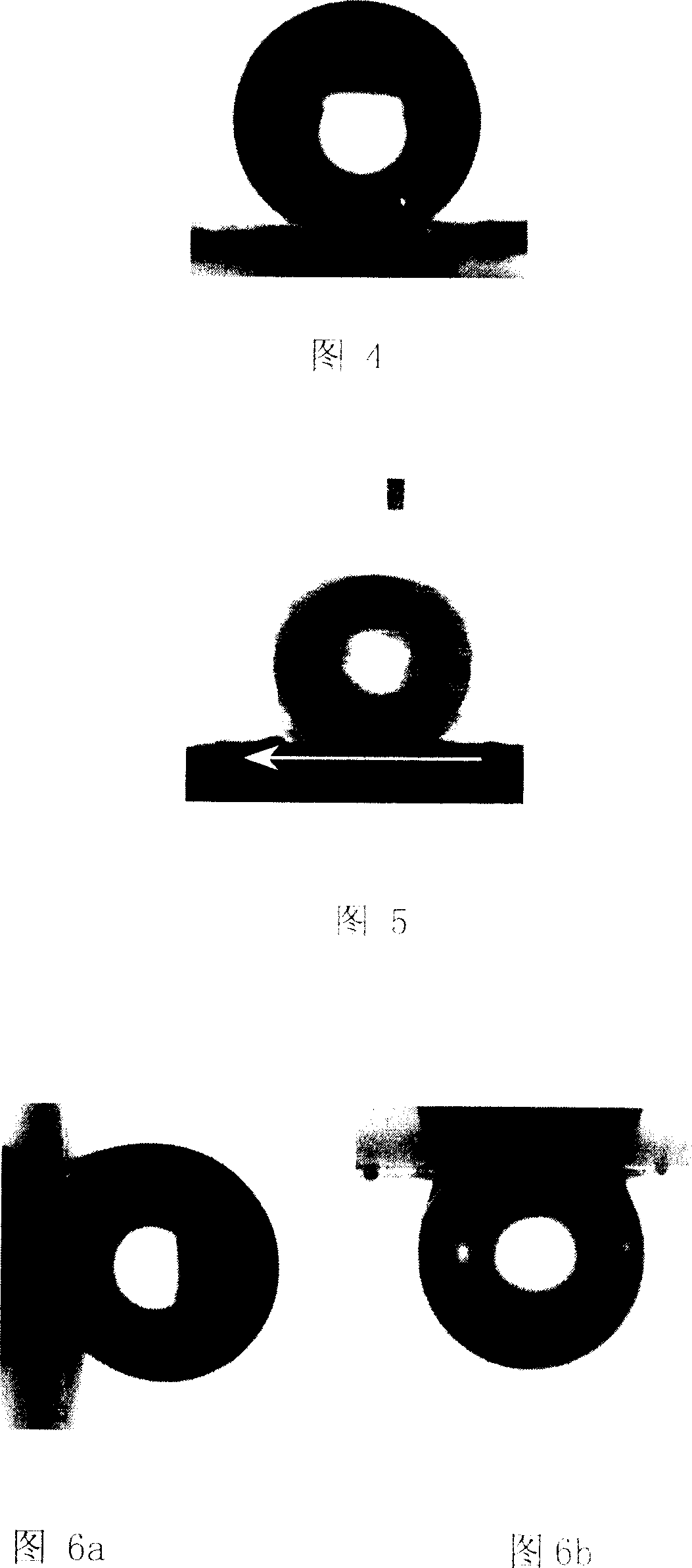

[0039] Use the solution configuration method, experimental equipment and sample drying method of Example 1. Put the 5wt% solution on the parallel plate and raise the temperature to 120°C; -1 While shearing, the temperature is lowered from 120°C to 65°C at a rate of 10°C / min, and then the shear is stopped and kept at 65°C until the structure is completely formed. Under such conditions, the polypropylene phase is separated from the solution, and at the same time The polypropylene in the propylene phase crystallizes to form a crystalline network structure with different morphology of the polypropylene film. The contact angle between the obtained polypropylene film and water is 161° (as shown in Figure 4), and the rolling angle is that the inclination angle of the substrate is less than 1°, and water droplets will roll off (as shown in Figure 5). The polypropylene film is composed of leaf-shaped polypropylene microcrystals as the basic unit to form a network structure, with holes...

Embodiment 3

[0041] With the solution configuration method, experimental equipment and sample drying method of embodiment 1, the solvent used is changed into a mixed solvent (volume ratio of 3: 2) of xylene and decahydronaphthalene, and the 10wt% solution is placed on a parallel plate, and the temperature rises to 100°C; the treatment process is to cool the solution from 100°C to 70°C at a rate of 15°C / min, and then apply at a rate of 2s -1 The shearing time is 10s, and then the temperature is lowered to 40°C at a rate of 15°C / min. Propylene crystallized to form a crystalline network structure with different morphology of the polypropylene film. The contact angle of the obtained polypropylene film with water is 155°, and the rolling angle is 32°. The polypropylene film is composed of crystallized microspheres and leaf-shaped polypropylene microcrystals as basic units to form a network structure, with pores of 2 to 40 microns. , wherein the crystallized polypropylene microspheres have a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com