Preparation method of high oil-carrying emulsion rich in fibrous polysaccharides

A technology of fiber polysaccharide and oil-in-water emulsion, which is applied in the field of food science, can solve the problems of high oil-carrying emulsion and limited oil phase, and achieve the effect of less dosage, strong emulsification and good viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

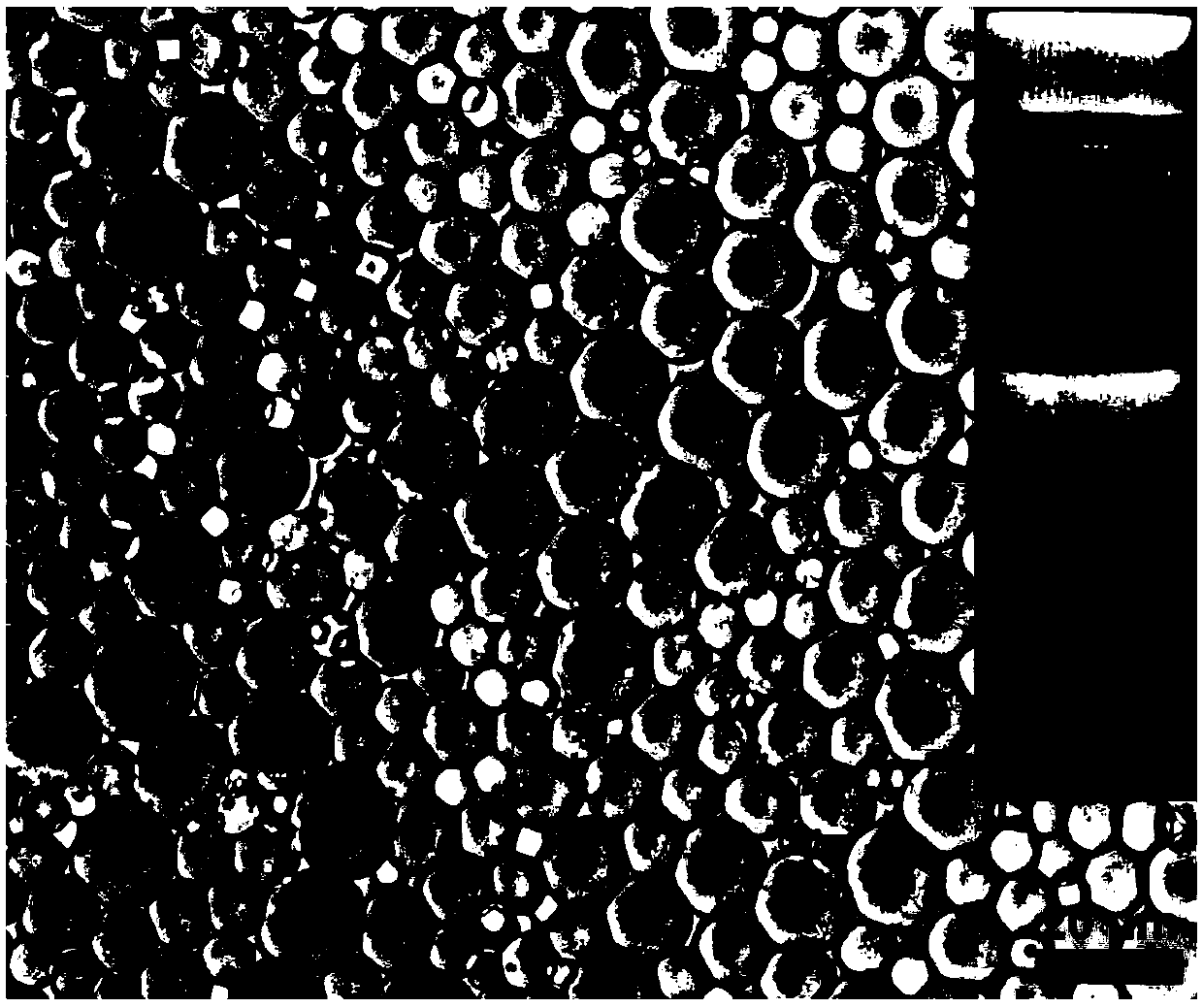

[0043]Example 1. Weigh 1 g of casein powder, add it to 100 mL of distilled water, stir it with a magnetic force at room temperature at 500 rpm for 30 minutes to dissolve evenly, and place it in a refrigerator at 4°C to hydrate to prepare a protein solution. The obtained protein solution was mixed with 0.2 g of microcrystalline cellulose powder prepared from pure wood pulp, and the pH was adjusted to 7 to obtain a uniformly mixed protein / fiber composite. Disperse 100mL of soybean oil in the prepared protein / fiber composite, and shear and disperse for 30 minutes at a shear speed of 5000rpm in a high-speed shearing machine to prepare an oil-in-water Pickering emulsion.

[0044] The surface of the emulsion sample prepared in this example has an oil layer precipitated out, the particle size is large and the distribution is uneven, and obvious stratification occurs after standing for 24 hours, and the emulsion is easy to flow.

Embodiment 2

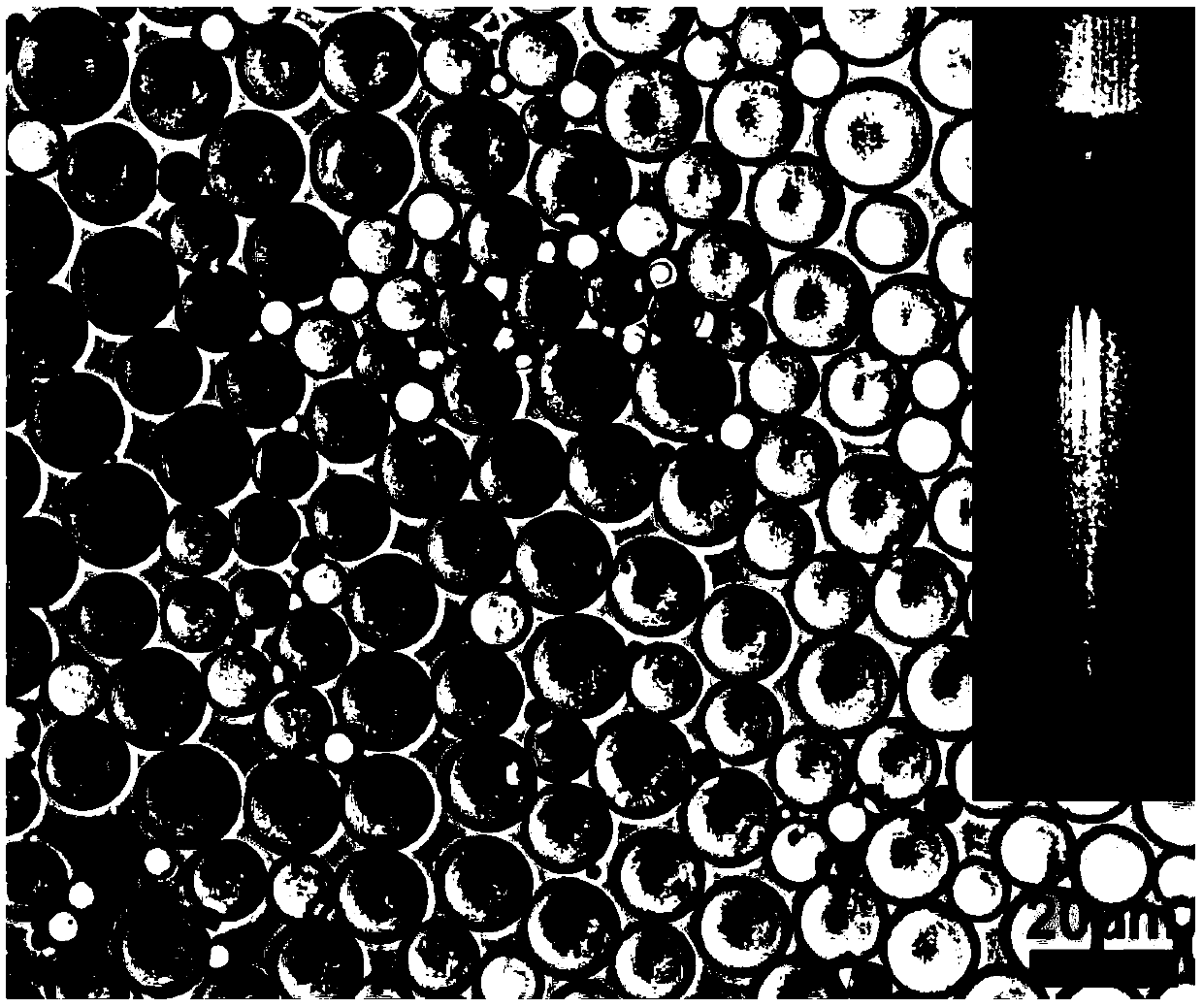

[0045] Example 2. Weigh 3 g of ovalbumin powder, add it to 100 mL of distilled water, stir it with a magnetic force at room temperature at 500 rpm for 30 minutes to dissolve evenly, and place it in a refrigerator at 4°C to hydrate to prepare a protein solution. The obtained protein solution was mixed with 0.15 g of microcrystalline cellulose powder prepared from pure wood pulp, and the pH was adjusted to 7 to obtain a uniformly mixed protein / fiber composite. Disperse 100mL soybean oil in the prepared protein / fiber composite, and shear and disperse for 20 minutes at 10000rpm in a high-speed shearing machine to prepare an oil-in-water Pickering emulsion.

[0046] On the surface of the emulsion prepared in this example, oil flakes were precipitated, the particle size distribution was uneven, and obvious stratification occurred after standing for 24 hours, and the emulsion was easy to flow.

Embodiment 3

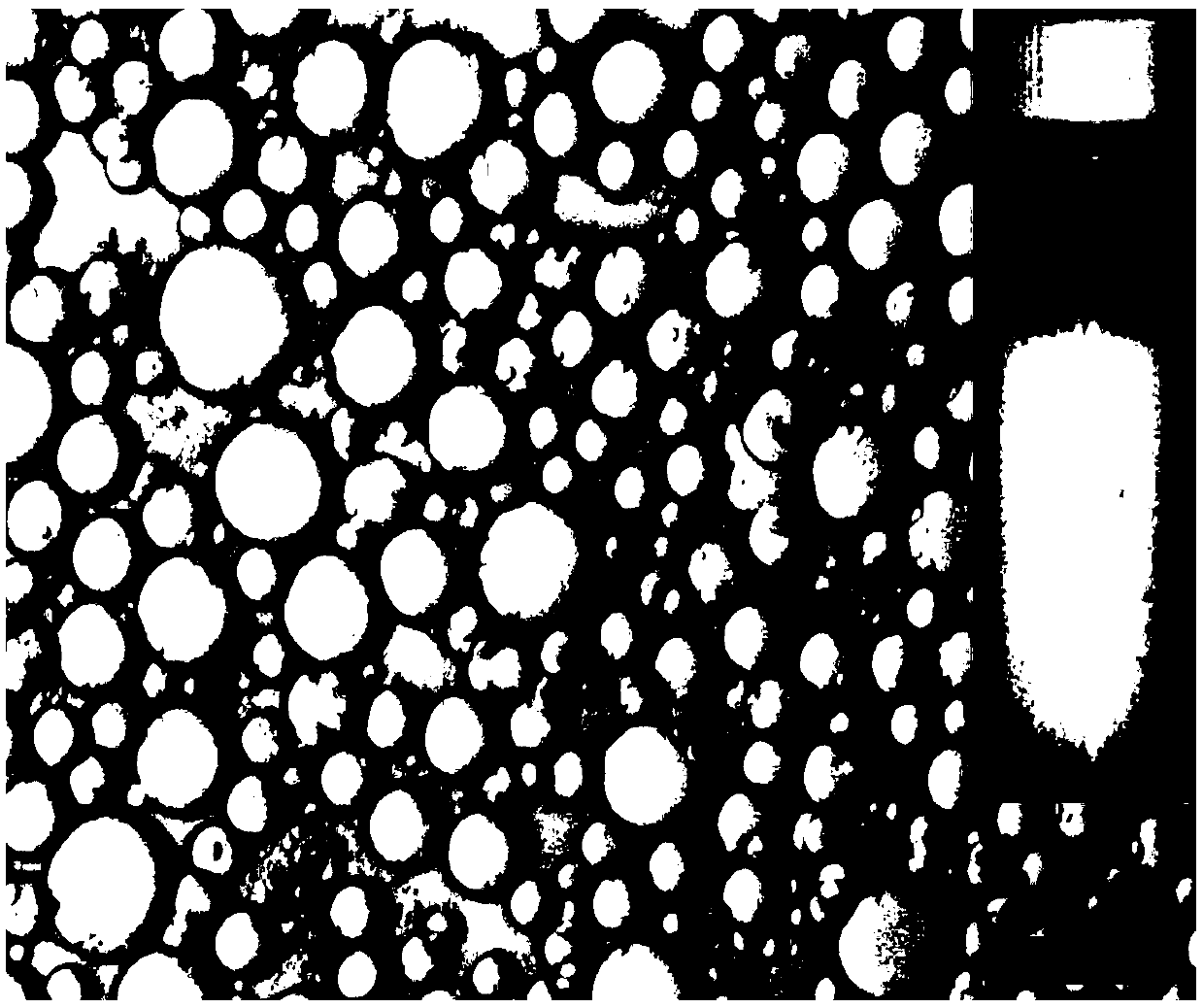

[0047] Example 3. Weigh 5 g of whey protein isolate powder, add it to 100 mL of distilled water, stir it with a magnetic force at room temperature at 500 rpm for 30 minutes to dissolve evenly, and place it in a refrigerator at 4°C to hydrate to prepare a protein solution. The obtained protein solution was mixed with 0.25 g of microcrystalline cellulose powder prepared from pure wood pulp, and the pH was adjusted to 7 to obtain a uniformly mixed protein / fiber composite. Disperse 100mL soybean oil in the prepared protein / fiber composite, and shear and disperse for 20 minutes at a shear speed of 12000rpm in a high-speed shearing machine to prepare an oil-in-water Pickering emulsion.

[0048] The emulsion sample prepared in this example has no oil precipitation, the emulsion particle size is large and the distribution is uneven, and obvious stratification occurs after standing for 24 hours, and the emulsion is easy to flow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com