Bi-component fluororesin coating and application thereof to photovoltaic module back plates

A two-component coating and photovoltaic module technology, applied in photovoltaic power generation, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor peeling performance, unsatisfactory compatibility, affecting the storage stability of coatings, etc. The network structure is stable and firm, the surface is smooth without spots, and the surface is not sticky

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

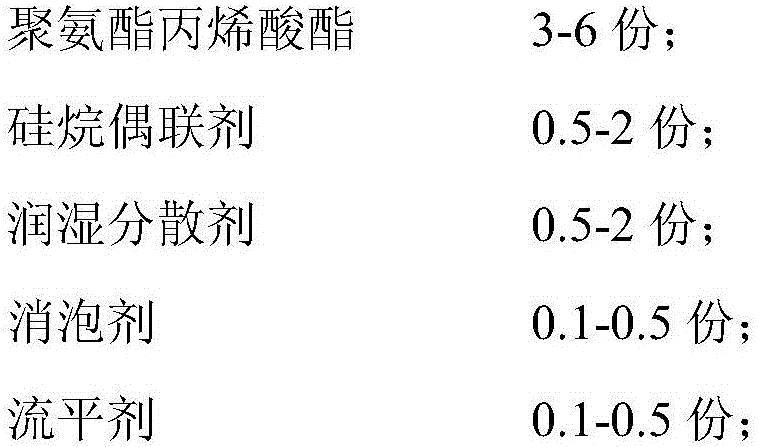

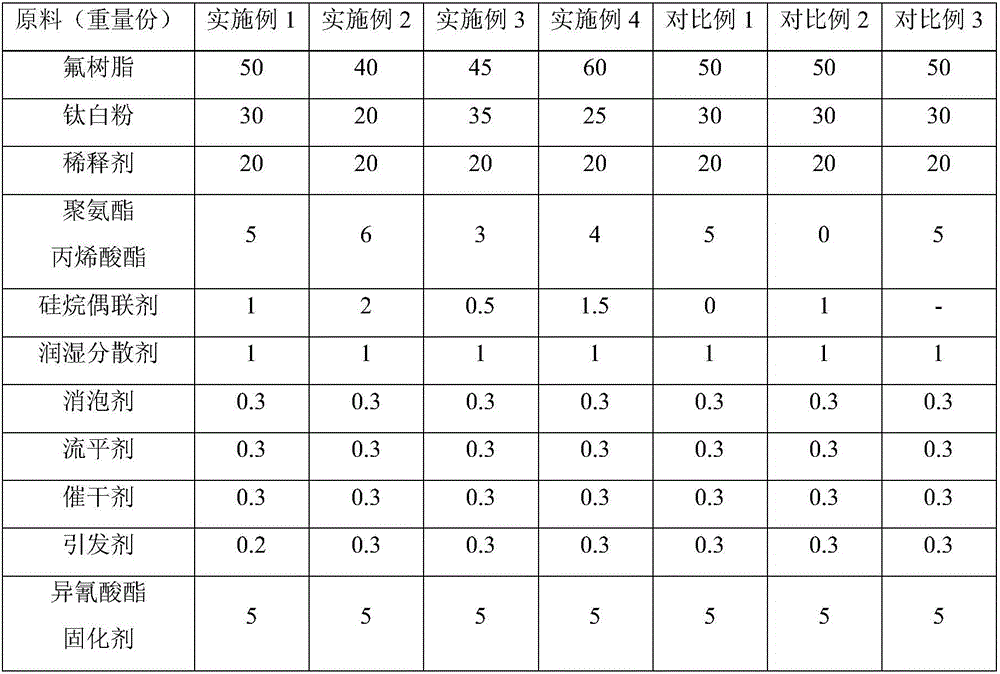

[0040] This embodiment provides a kind of fluororesin two-component paint, and the raw materials and formulations used are shown in Table 1, wherein,

[0041] The fluororesin comes from Changxing Chemical Industry (China) Co., Ltd., and the brand name is 41011.

[0042] Polyurethane acrylate comes from Jiangsu Sanmu Chemical Co., Ltd., and the brand is 6205.

[0043] The silane coupling agent is vinyltrimethoxysilane.

[0044] The initiator is tert-butyl benzoyl peroxide.

[0045] The isocyanate curing agent is HDI trimer.

[0046] In this example, the preparation of component A: According to the formula, mix fluororesin, titanium dioxide, polyurethane acrylate, silane coupling agent, wetting and dispersing agent, defoamer, leveling agent, and diluent evenly, and grind to Particle fineness ≤10μm, as component A, for future use.

[0047] Preparation of component B: According to the formula, mix the isocyanate curing agent, initiator and drier evenly, and use it as component...

Embodiment 2

[0051] This embodiment provides a kind of fluororesin two-component paint, and the raw materials and formulations used are shown in Table 1, wherein,

[0052] The fluororesin comes from Daikin Fluororesin Company of Japan, the brand is GK570.

[0053] Polyurethane acrylate comes from Jiangsu Sanmu Chemical Co., Ltd., and the brand name is 6202.

[0054] The silane coupling agent is γ-methacryloxypropyltrimethoxysilane.

[0055] The initiator is azobisisobutyronitrile.

[0056] The isocyanate curing agent is IPDI.

[0057]In this example, the mass ratio of component A and component B for preparing the photovoltaic module backsheet is 5:1, and the others are the same as in Example 1.

Embodiment 3

[0059] This embodiment provides a kind of fluororesin two-component paint, and the raw materials and formulations used are shown in Table 1, wherein,

[0060] The fluororesin comes from Changxing Chemical Industry (China) Co., Ltd., the brand is 41018.

[0061] Polyurethane acrylate comes from Jiangsu Sanmu Chemical Co., Ltd., and the brand is 6205.

[0062] The silane coupling agent is a combination of vinyltriethoxysilane and vinyltris(β-methoxyethoxy)silane in a mass ratio of 1:1.

[0063] The initiator is azobisisobutyronitrile.

[0064] In this example, the mass ratio of component A and component B for preparing the photovoltaic module backsheet is 5:1, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com