Hydrophobically associating crosslinked polymer microspheres, preparation method and application

A technology of cross-linked polymers and hydrophobic association, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of poor temperature and salt resistance of polymer microspheres, high viscosity and stable volume of polymer microspheres Poor performance and other problems, to achieve significant temperature resistance and salt resistance, large space cross-linking density, and stable network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of described sodium lauryl alcohol maleate comprises:

[0044]Mix dodecyl alcohol, maleic anhydride and an organic solvent, and react under the action of a catalyst at 80-85°C to obtain sodium dodecyl alcohol maleate;

[0045] Preferably, the molar ratio of said lauryl alcohol to said maleic anhydride is 1:1; and

[0046] The catalyst is S 2 o 8 2- / ZrO 2 -SiO 2 .

[0047] Lauryl alcohol sodium maleate used in the present invention is to be by lauryl alcohol and maleic anhydride by esterification synthesis monoester, then add alkali and make reactive emulsifier sodium lauryl alcohol maleate, its preparation method is : Mix dodecyl alcohol and maleic anhydride with a molar ratio of 1:1, and add an organic solvent, such as petroleum ether with a monomer mass of 50%, fully mix it and add it into a four-necked flask, and install a condenser on the four-necked flask. Stirrer, thermometer, 0.8% catalyst S 2 o 8 2- / ZrO 2 -SiO 2 Add it into a...

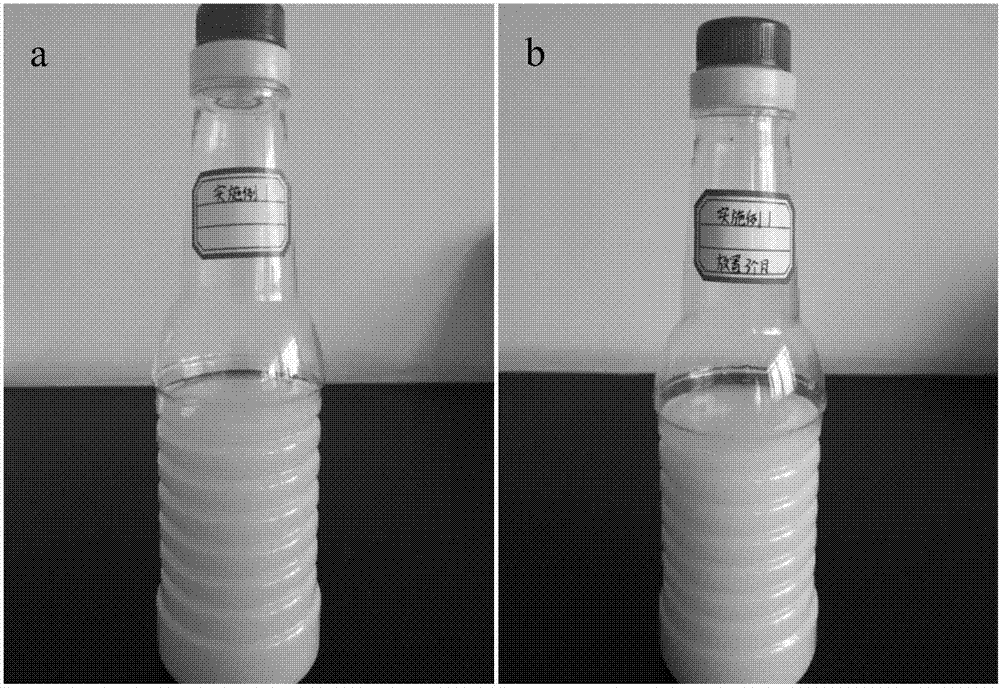

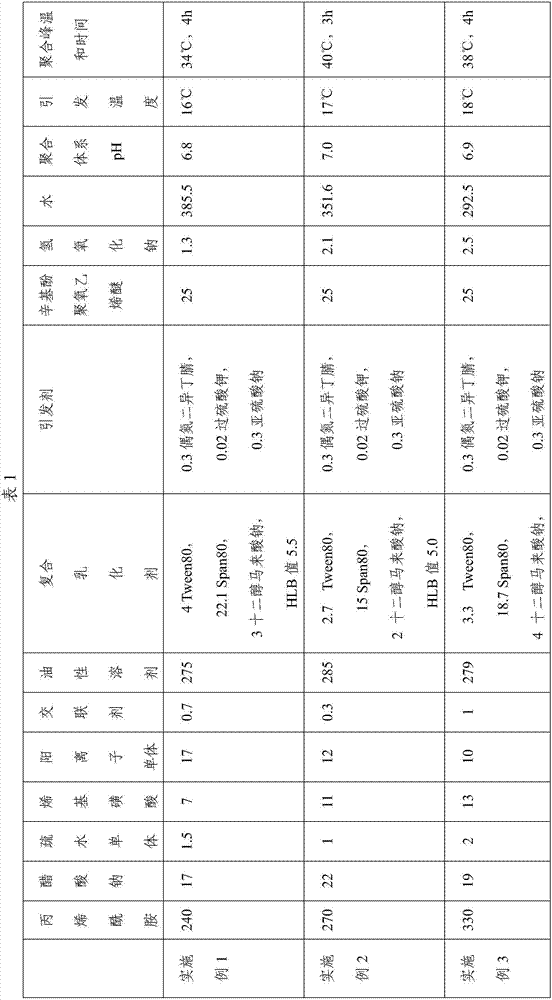

Embodiment 1

[0067] The weight parts of raw materials are: acrylamide 240, sodium acetate 17, N-dodecyl acrylamide 1.5, 2-acrylamide-2-methylpropanesulfonic acid 7, dimethyl diallyl ammonium chloride 17, N , N-methylenebisacrylamide 0.7, sodium hydroxide 1.3, deionized water 385.5, white oil 275, Tween804, Span80 22.1, reactive emulsifier sodium lauryl maleate 3 (Tween80, Span80 and reactive emulsifier The HLB value after mixing the agent is 5.5), octylphenol polyoxyethylene ether 25, azobisisobutyronitrile 0.3, potassium persulfate 0.02, sodium sulfite 0.3.

[0068] The preparation method is: add acrylamide, sodium acetate, N-dodecylacrylamide, 2-acrylamide-2-methylpropanesulfonic acid, dimethyl diallyl ammonium chloride, N,N-methylenebisacrylamide and water, mix well and adjust the pH value to 6.8 with sodium hydroxide, then add white oil, Tween80, Span80, reactive emulsifier and initiator azobisisobutyronitrile , Potassium persulfate, stirred at high speed for 2 minutes, transferred to...

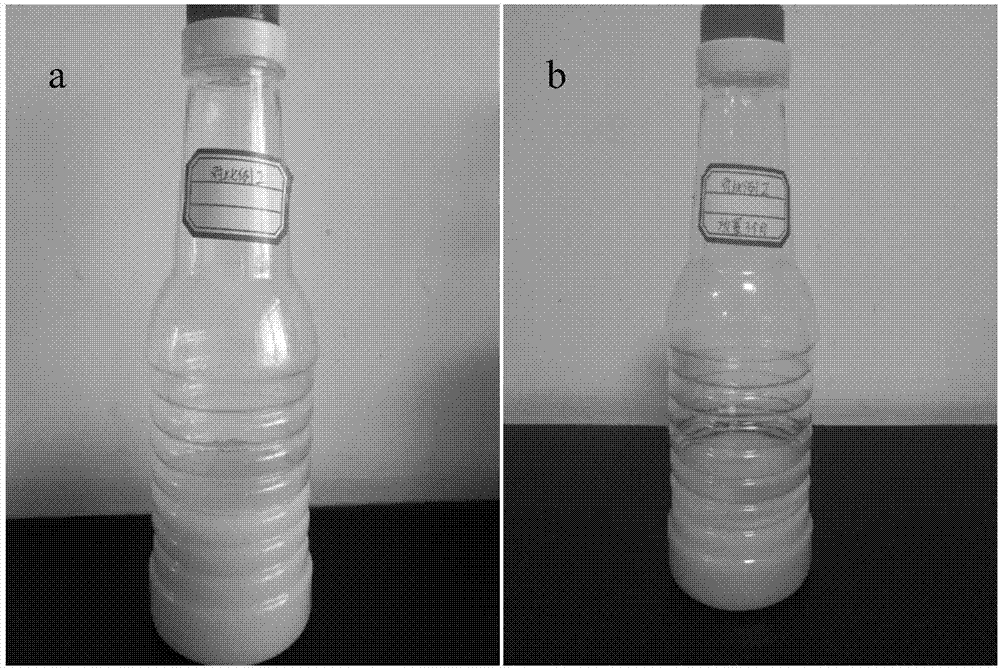

Embodiment 2

[0071] The parts by weight of raw materials are: acrylamide 270, sodium acetate 22, styrene 1, 2-acrylamide-2-methylpropanesulfonic acid 11, dimethyl diallyl ammonium chloride 12, N,N-methylene Bisacrylamide 0.3, sodium hydroxide 2.1, deionized water 351.6, white oil 285, Tween80 2.7, Span80 15, reactive emulsifier sodium lauryl maleate 2 (HLB after mixing Tween80, Span80 and reactive emulsifier Value is 5.0), octylphenol polyoxyethylene ether 25, azobisisobutyronitrile 0.3, potassium persulfate 0.02, sodium sulfite 0.3.

[0072] The preparation method is: add acrylamide, sodium acetate, styrene, 2-acrylamide-2-methylpropanesulfonic acid, dimethyl diallyl ammonium chloride, N,N-methylene base bisacrylamide and water, mix well and adjust the pH value to 7.0 with sodium hydroxide, then add white oil, Tween80, Span80, reactive emulsifier and initiator azobisisobutyronitrile, potassium persulfate Stir for 2 minutes, transfer to the reaction kettle, pass nitrogen to remove oxygen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com