Complex enzyme preparation and beverage prepared by using complex enzyme preparation

A compound enzyme preparation and beverage technology, applied in the field of food and beverage, can solve the problems of reducing consumers' acceptance of oatmeal beverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] According to one aspect of the present invention, a kind of preparation method of above-mentioned beverage, described preparation method comprises the following steps:

[0061] The above compound enzyme preparation is added to the oat slurry for enzymolysis to obtain an oat enzymatic hydrolysis liquid, which is then formulated to obtain an oat protein beverage.

[0062] The preparation method of the beverage provided by the present invention comprises the following steps: first, adding the above-mentioned compound enzyme preparation to the oat slurry for enzymolysis to obtain an oat enzymatic hydrolyzate, and then blending to obtain an oat protein beverage. The above method has the advantages of simple preparation process and easy operation.

[0063] In a preferred embodiment of the present invention, the enzymolysis is enzymolysis at a temperature of 45-65°C for 40-120 minutes;

[0064] In the preferred embodiment described above, the enzymatic hydrolysis includes the...

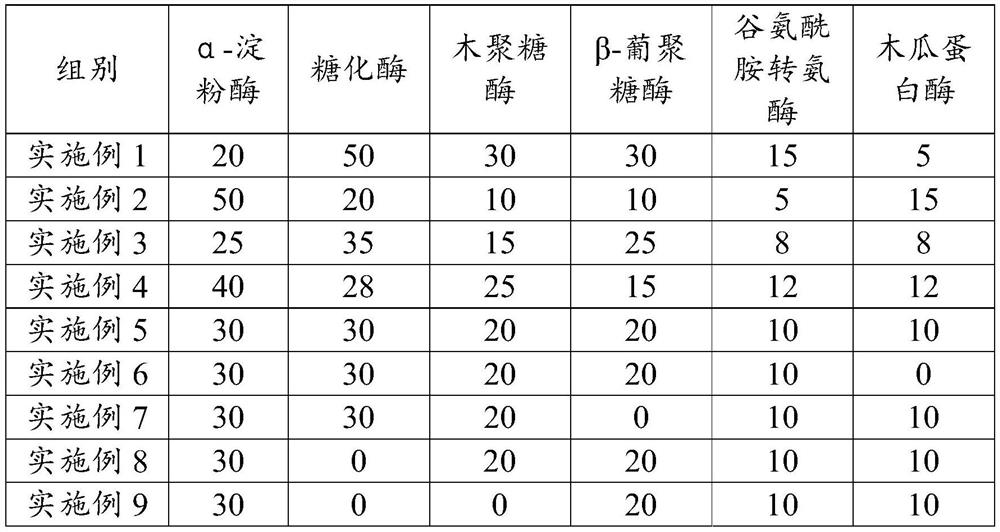

Embodiment 1~9

[0089] A compound enzyme preparation, in parts by mass, said compound enzyme preparation comprises the following raw materials:

[0090]

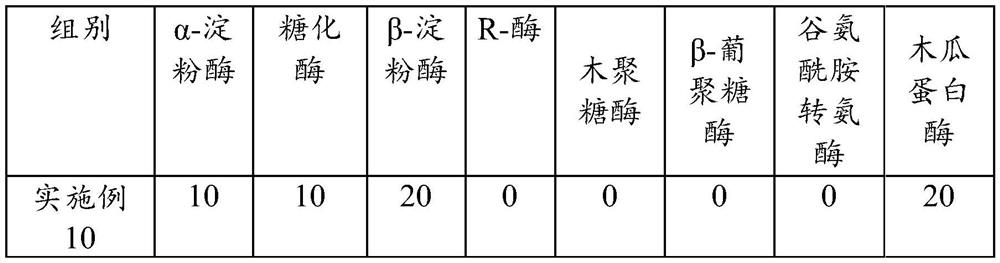

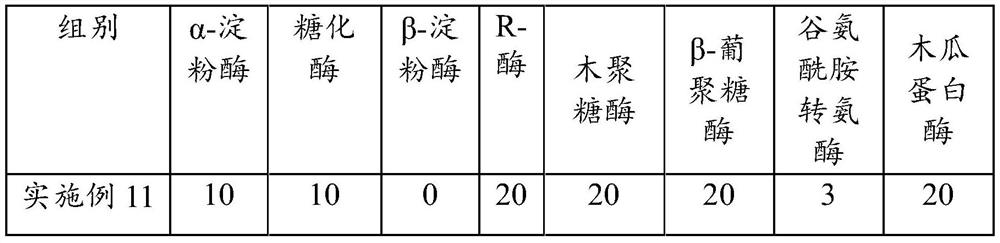

Embodiment 10

[0098] A preparation method of oat protein drink, said method comprising the following steps:

[0099] (a) Pulping: Provide oat grains, incubate the oat grains at 90-110°C for 10-30 minutes to inactivate enzymes, then lower the temperature to 50°C; then mix the enzyme-inactivated oat grains with water at a ratio of 1:3 After mixing and grinding, oatmeal slurry is obtained;

[0100] The temperature of the water is 20°C;

[0101] (b), enzymolysis: the oat slurry obtained in step (a) was heated to 45°C, and then the compound enzyme preparation prepared in Example 1 was added for enzymolysis for 30 minutes to obtain enzymolysis solution A;

[0102] Heat the enzymolysis solution A to 55°C and perform enzymolysis for 30 minutes to obtain enzymolysis solution B;

[0103] Cool the enzymatic solution B to 20°C, remove the precipitate, and obtain the enzymatic solution C;

[0104] Heat the enzymatic hydrolysis solution C to 90°C, inactivate the enzyme for 10 minutes, then cool to 50°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com