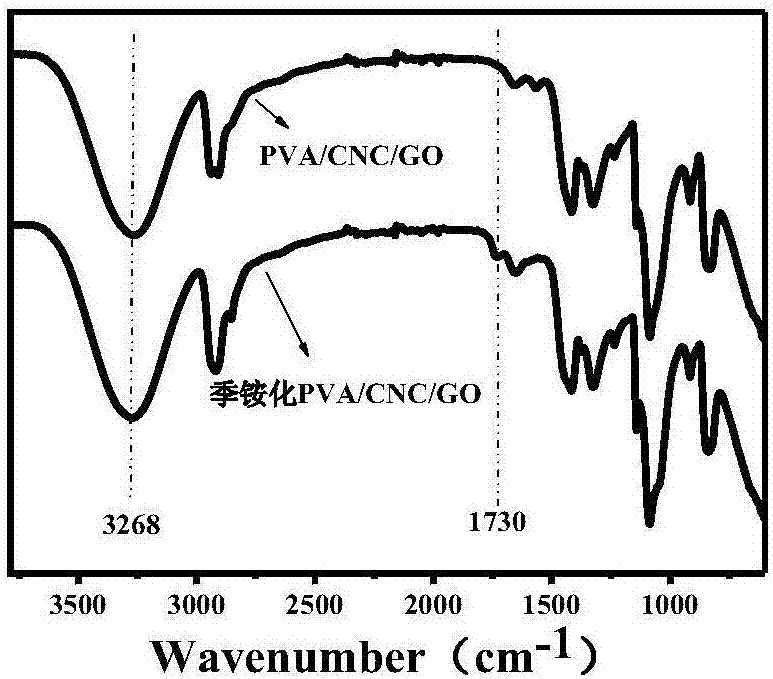

Preparation method of quaternary ammonium salt polyvinyl alcohol-cellulose-graphene oxide composite membrane

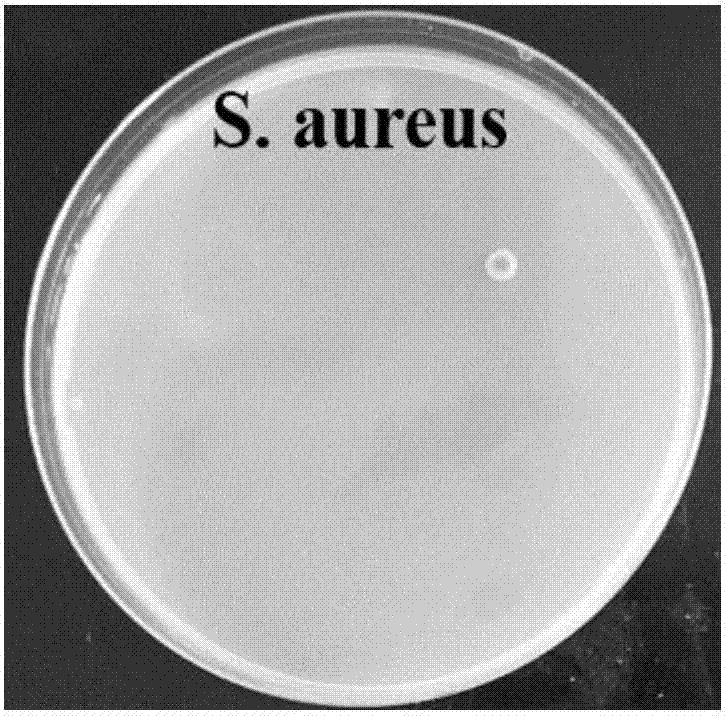

A compound technology of salinized polyvinyl alcohol and graphene, which is applied in the field of polymer materials, can solve the problems of small molecule antibacterial agents such as easy volatilization, difficult processing, and poor chemical stability, and achieve excellent antibacterial activity and improve water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of CNC and GO composite dispersion (CNC / GO): Mix CNC and GO aqueous dispersion at a mass ratio of CNC and GO of 1:2, stir at room temperature for 10 min, and adjust CNC / GO composite liquid with deionized water The concentration is 0.005g / mL, and then ultrasonically dispersed in a 100W ultrasonic cleaner for 30 minutes to obtain a CNC / GO composite dispersion;

[0025] (2) Preparation of PVA / CNC / GO composite membrane: 2g of PVA was stirred and dissolved in 25mL of deionized water at 90°C to obtain a uniform PVA aqueous solution; the CNC / GO composite dispersion obtained in the above step (1) was added to Into the PVA aqueous solution, control the CNC / GO composite nanoparticles to be 3% of the PVA mass, and stir at 50°C to 60°C for 20 minutes to obtain the PVA / CNC / GO composite liquid; after the PVA / CNC / GO mixed liquid is left to defoam Pour it into a glass mold, let it stand at room temperature for 12 hours, and then dry it at 40°C for 3 hours to obtain a PV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com