Jelly and making method thereof

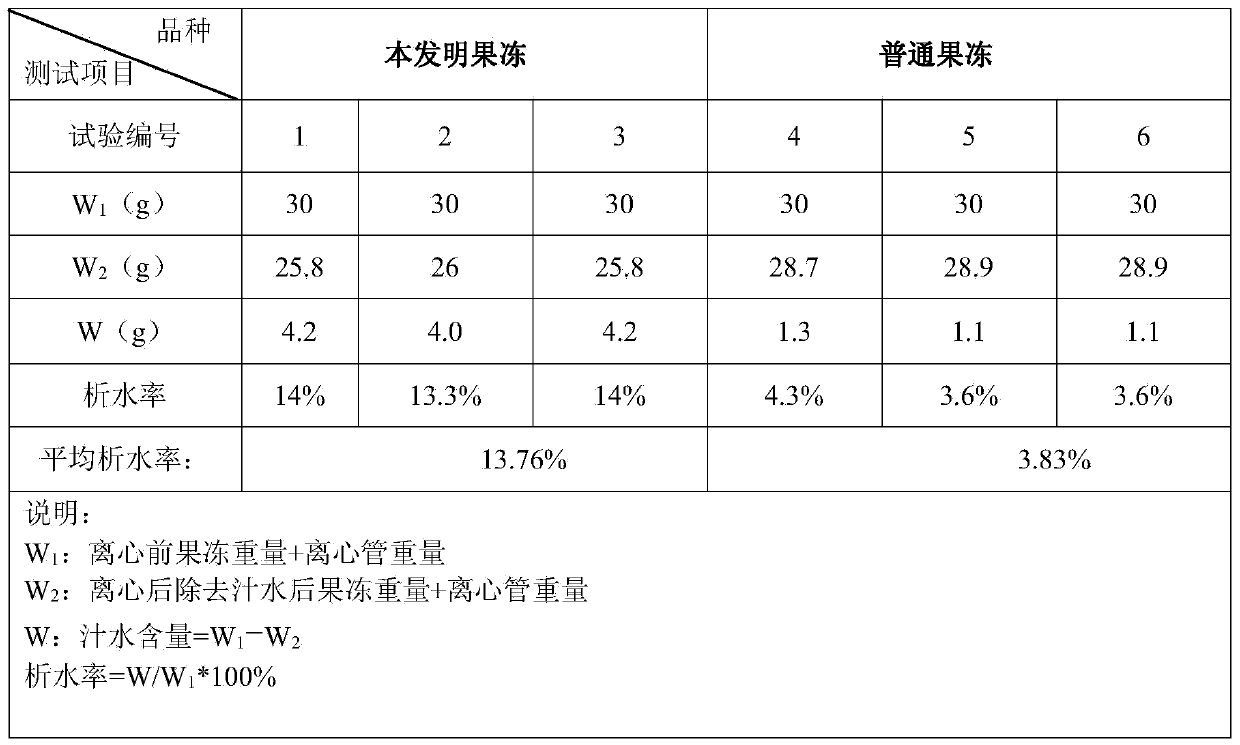

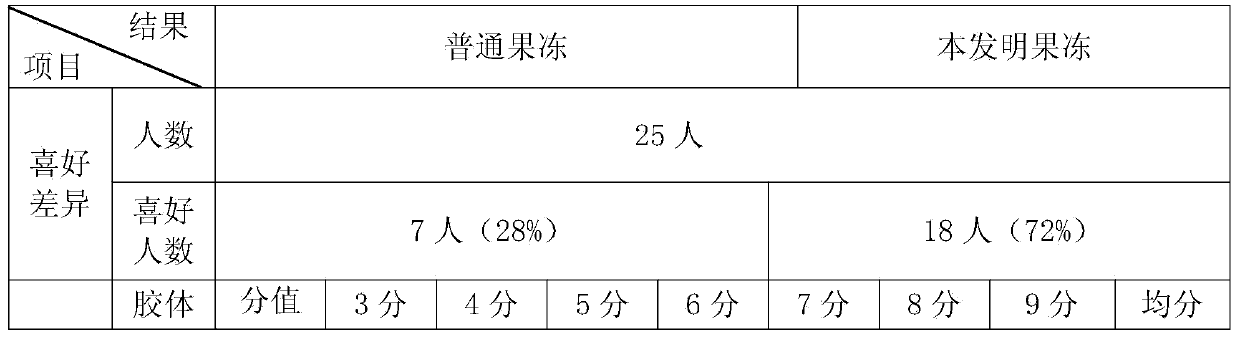

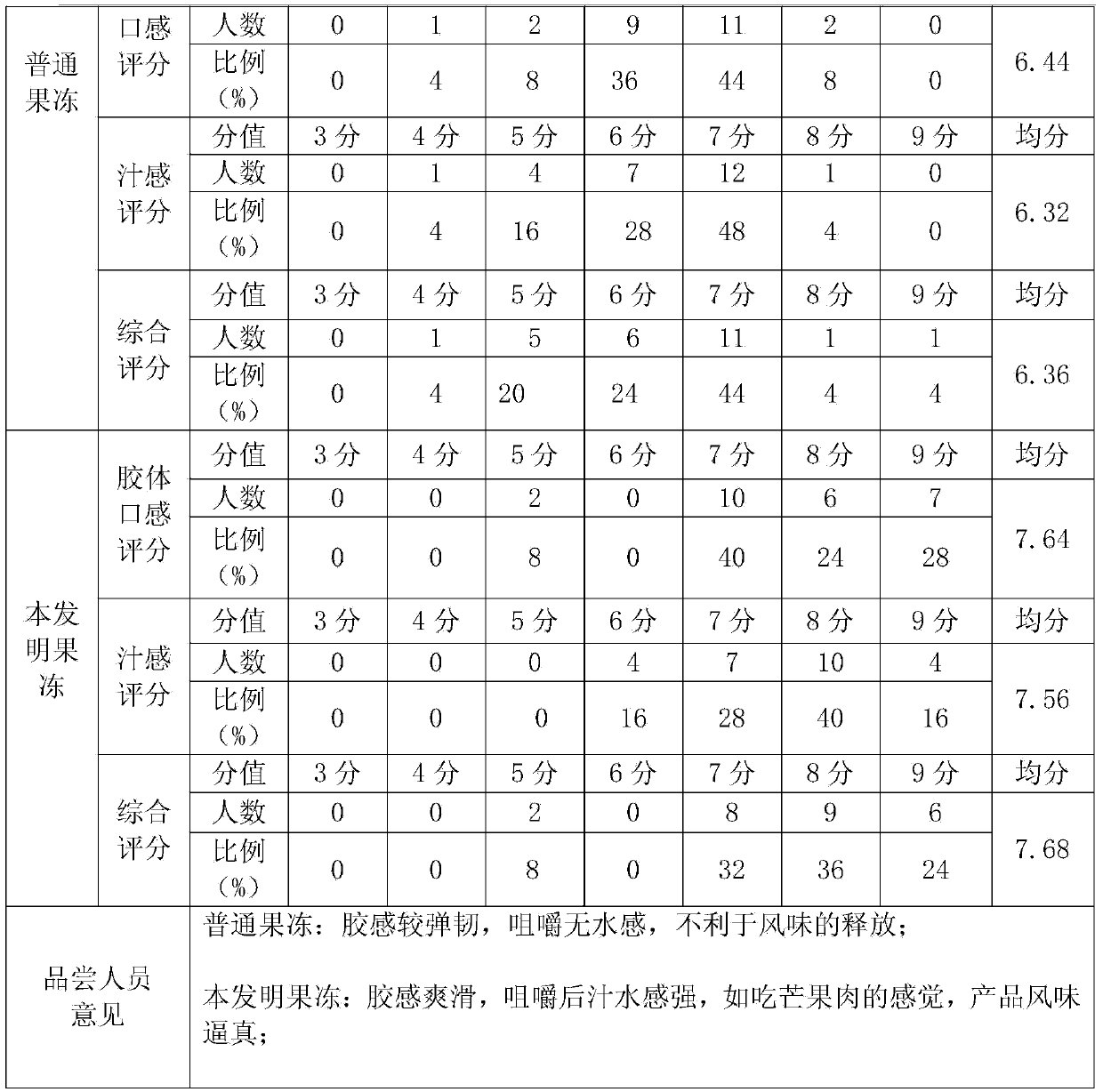

A production method and jelly technology, applied in the field of food processing, can solve the problems of affecting the taste and appearance of products, single taste of jelly products, easy to separate out water, etc., and achieve the effect of enhancing product value and enriching product content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Prepare raw materials by weight:

[0023] 5 parts of compound starch, 1.0 part of compound thickener, 5 parts of fruit pulp, 10 parts of white sugar, 10 parts of fructose syrup, 0.6 part of citric acid, 0.05 part of sodium citrate, 45 parts of process water, 0.001 part of pigment, 0.08 parts of essence and 10 parts of pulp. The weight ratio of the large-grained starch to the small-granular starch in the compound starch is 1:0.6; the particle diameter of the large-granule starch is 40-50 μm, and the particle diameter of the small-granule starch is 5-10 μm; the compound thickener consists of the following Mixing composition by weight ratio: 30 parts of carrageenan, 20 parts of konjac gum, 20 parts of locust bean gum, 1 part of gellan gum, 10 parts of xanthan gum, 2 parts of agar, 5 parts of potassium chloride, and 10 parts of calcium lactate.

[0024] The production method is as follows:

[0025] S1 Add the compound starch to the process water at room temperature to sti...

Embodiment 2

[0030] Prepare raw materials by weight:

[0031] 10 parts of compound starch, 2 parts of compound thickener, 10 parts of fruit pulp, 20 parts of white sugar, 15 parts of fructose syrup, 0.8 parts of citric acid, 0.1 part of sodium citrate, 75 parts of process water, 0.002 parts of pigment, 0.1 parts of essence, 20 parts of pulp. The weight ratio of large granule starch to small granule starch in the compound starch is 1:2.5; the particle size of the large granule starch is 50-65 μm, and the particle size of the small granule starch is 10-20 μm; the compound thickener consists of the following Mixing composition in parts by weight: 60 parts of carrageenan, 50 parts of konjac gum, 50 parts of locust bean gum, 3 parts of gellan gum, 20 parts of xanthan gum, 10 parts of agar, 9 parts of potassium chloride, and 30 parts of calcium lactate.

[0032] The production method is as follows:

[0033] S1 Add the compound starch to the process water at room temperature to stir and dispers...

Embodiment 3

[0038] Prepare raw materials by weight:

[0039] 8 parts of compound starch, 1.5 parts of compound thickener, 8 parts of fruit pulp, 15 parts of white sugar, 12 parts of fructose syrup, 0.7 parts of citric acid, 0.08 parts of sodium citrate, 60 parts of process water, 0.001 part of pigment, 0.1 parts of essence, 15 parts of pulp. The weight ratio of large granule starch to small granule starch in the compound starch is 1:1.6; the particle size of the large granule starch is 45-55 μm, and the particle size of the small granule starch is 8-15 μm; the compound thickener consists of the following Mixing composition in proportion by weight: 45 parts of carrageenan, 35 parts of konjac gum, 35 parts of locust bean gum, 2 parts of gellan gum, 15 parts of xanthan gum, 6 parts of agar, 7 parts of potassium chloride, and 20 parts of calcium lactate.

[0040] The production method is as follows:

[0041] S1 Add the compound starch to the process water at room temperature to stir and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com