Milk cubilose can and preparation method thereof

A technology of canned bird's nest and a production method, which is applied in the directions of milk preparations, dairy products, and milk preservation, etc., can solve the problems such as the nutrient components are not easily absorbed by those who eat them, the retained nutrient components are low, and the nutrient absorption effect is poor, so as to achieve good health care. effect, enhance the taste, reduce the effect of the expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

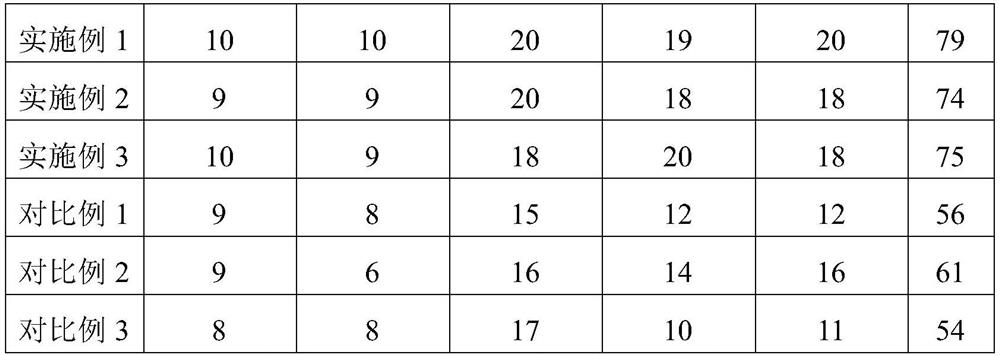

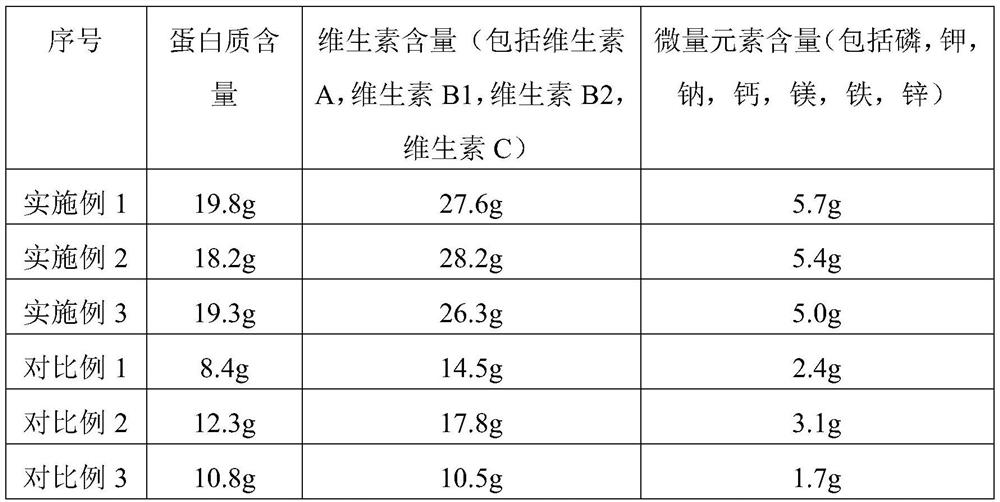

Embodiment 1

[0031] A milk bird's nest can, comprising the following components in parts by weight: 55 parts of milk, 6 parts of bird's nest, 6 parts of rock sugar, 2 parts of starch and 45 parts of distilled water.

[0032] A method for making the above-mentioned milk bird's nest can, comprising the following steps:

[0033] S1: Add rock sugar to distilled water, stir to dissolve to obtain sugar water;

[0034] S2: Stir and mix the starch and half the weight of the syrup obtained in step S1 evenly, and heat to 60-70°C to obtain the starch-based syrup;

[0035] Take milk and add it to the remaining sugar water obtained in step S1 to obtain milk base sugar water;

[0036] S3: Breaking the bird's nest into three-gradient crushed materials, the three-gradient crushed materials include: the first gradient crushed material with a particle size of 150-250 mesh, the second gradient crushed material with a particle size of 50-100 mesh, and a particle size of 0 -50 purpose third gradient crushed ...

Embodiment 2

[0049] A milk bird's nest can, comprising the following components by weight: 45 parts of milk, 2 parts of bird's nest, 2 parts of rock sugar, 1 part of starch and 35 parts of distilled water.

[0050] A method for making the above-mentioned milk bird's nest can, comprising the following steps:

[0051] S1: Add rock sugar to distilled water, stir to dissolve to obtain sugar water;

[0052] S2: Stir and mix the starch and half the weight of the syrup obtained in step S1 evenly, and heat to 60-70°C to obtain the starch-based syrup;

[0053] Take milk and add it to the remaining sugar water obtained in step S1 to obtain milk base sugar water;

[0054] S3: Breaking the bird's nest into three-gradient crushed materials, the three-gradient crushed materials include: the first gradient crushed material with a particle size of 150-250 mesh, the second gradient crushed material with a particle size of 50-100 mesh, and a particle size of 0 -50 purpose third gradient crushed material; ...

Embodiment 3

[0067] A milk bird's nest can, comprising the following components in parts by weight: 50 parts of milk, 4 parts of bird's nest, 4 parts of rock sugar, 1.5 parts of starch and 40 parts of distilled water.

[0068] A method for making the above-mentioned milk bird's nest can, comprising the following steps:

[0069] S1: Add rock sugar to distilled water, stir to dissolve to obtain sugar water;

[0070] S2: Stir and mix the starch and half the weight of the syrup obtained in step S1 evenly, and heat to 60-70°C to obtain the starch-based syrup;

[0071] Take milk and add it to the remaining sugar water obtained in step S1 to obtain milk base sugar water;

[0072] S3: Breaking the bird's nest into three-gradient crushed materials, the three-gradient crushed materials include: the first gradient crushed material with a particle size of 150-250 mesh, the second gradient crushed material with a particle size of 50-100 mesh, and a particle size of 0 -50 purpose third gradient crushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com