Mixed hyaluronic-acid gel and preparation method thereof

A technology of hyaluronic acid and sodium hyaluronate, which is used in pharmaceutical formulations, medical science, prostheses, etc., can solve the problem of not guaranteeing the retention time of hyaluronic acid, and achieve excellent rheological properties, good mechanical properties, and network Strong and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] An embodiment of the present invention provides a method for preparing a mixed hyaluronic acid gel, the method comprising:

[0035] S1, reacting sodium hyaluronate with a cross-linking agent at a pH value of 9-13 to obtain a cross-linked sodium hyaluronate gel;

[0036] S2, reacting the polynucleotide with a cross-linking agent under the condition of a pH value of 2-5 to obtain a cross-linked nucleotide gel;

[0037] S3. After mixing the cross-linked sodium hyaluronate gel and the cross-linked nucleotide gel, react with the cross-linking agent again, adjust the pH value to neutral, and prepare a mixed transparent Hyaluronic Acid Gel.

[0038] Wherein, the implementation of step S1 and step S2 is not limited in order and can be performed at the same time, which can shorten the process cycle and effectively improve production efficiency.

[0039] In practice, hyaluronic acid usually exists in the form of hyaluronate, such as sodium salt, potassium salt, etc., and sodium...

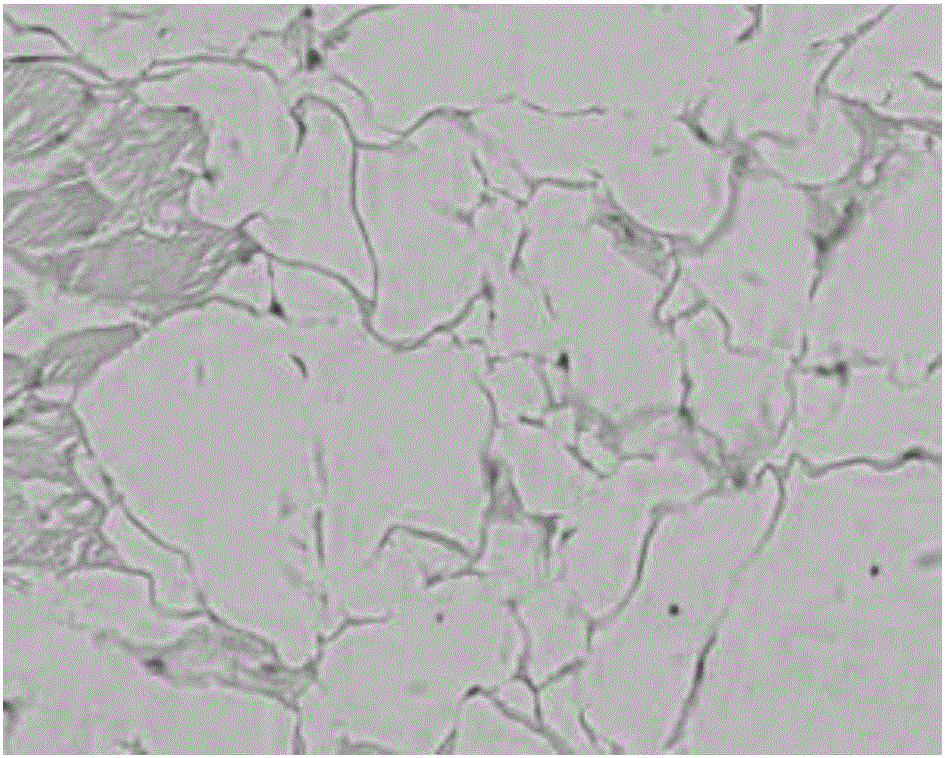

Embodiment 1

[0066] (1) Dissolve 5.0g of sodium hyaluronate in 50mL of NaOH solution with a pH value of 12, stir evenly, add 0.03g of 1,4-butanediol diglycidyl ether cross-linking agent, mix well, and place in a water bath at 40°C After 3 hours, a cross-linked sodium hyaluronate gel was obtained; wherein, the molecular weight of sodium hyaluronate was 2 million Daltons;

[0067] (2) Dissolve 5.0g of polynucleotide in the HCl solution with a pH value of 3, stir evenly, add 0.025g of 1,4-butanediol diglycidyl ether cross-linking agent, mix evenly, and place at 30°C Submerged in a water bath for 6 hours to obtain a cross-linked nucleotide gel; wherein, the molecular weight of the polynucleotide is 500 Daltons;

[0068] (3) Mix 50 g of cross-linked sodium hyaluronate gel and cross-linked nucleotide gel, adjust the pH to 3-5, add 0.05 g of 1,4-butanediol diglycidyl ether cross-linking agent, and mix After uniformity, put it in a water bath at 30°C for 6 hours, then adjust the pH to 7.0 with so...

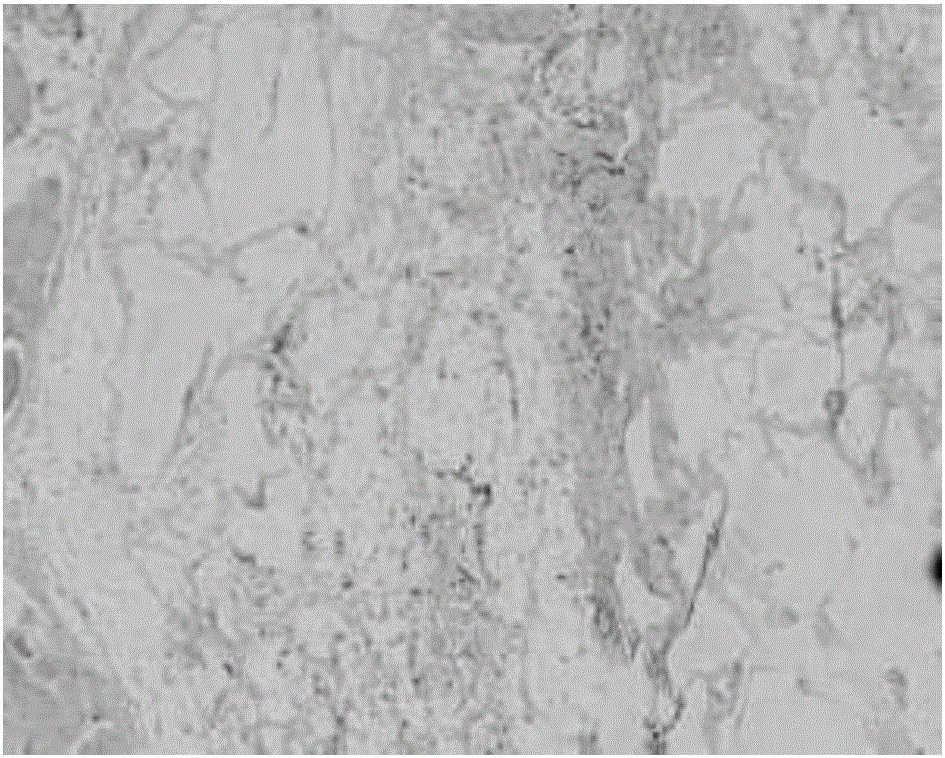

Embodiment 2

[0072] (1) Dissolve 5.0g of sodium hyaluronate in 50mL of NaOH solution with a pH value of 13, stir evenly, add 0.075g of 1,4-butanediol diglycidyl ether cross-linking agent, mix well, and place at 37°C Submerged in a water bath for 12 hours to obtain a cross-linked sodium hyaluronate gel; wherein, the molecular weight of sodium hyaluronate is 2 million Daltons;

[0073] (2) Dissolve 3.0g polynucleotide in HCl solution with pH value of 4, stir well, add 0.006g 1,4-butanediol diglycidyl ether cross-linking agent, mix well and place at 40°C Submerged in a water bath for 3 hours to obtain a cross-linked nucleotide gel; wherein, the molecular weight of the polynucleotide is 10,000 Daltons;

[0074] (3) Take 50 g of cross-linked sodium hyaluronate gel, and then take 20 g of cross-linked nucleotide gel for mixing, adjust the pH to 3-5, add 0.035 g of 1,4-butanediol diglycidyl ether cross-linking agent , after mixing evenly, place in a water bath at 30°C for 6 hours, then adjust the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com