Preparation method of antibacterial polyvinyl alcohol/cellulose nanocrystal-graphene oxide (PVA/CNC-GO) composite film

A technology of polyvinyl alcohol and composite film, which is applied in the field of adding CNC, GO, Ag to obtain water-resistant and antibacterial composite materials, which can solve the problems of limited application, barrier property, and strength decline, and achieve excellent antibacterial activity and improve water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

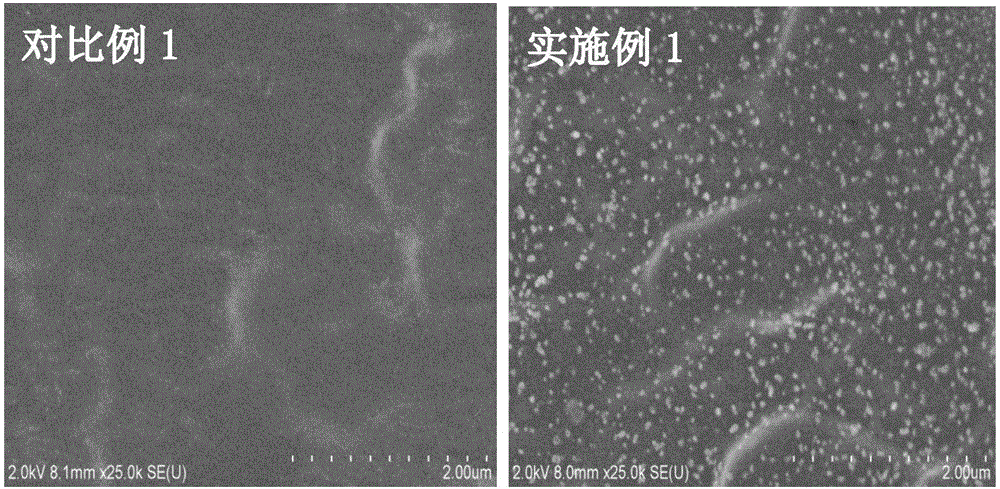

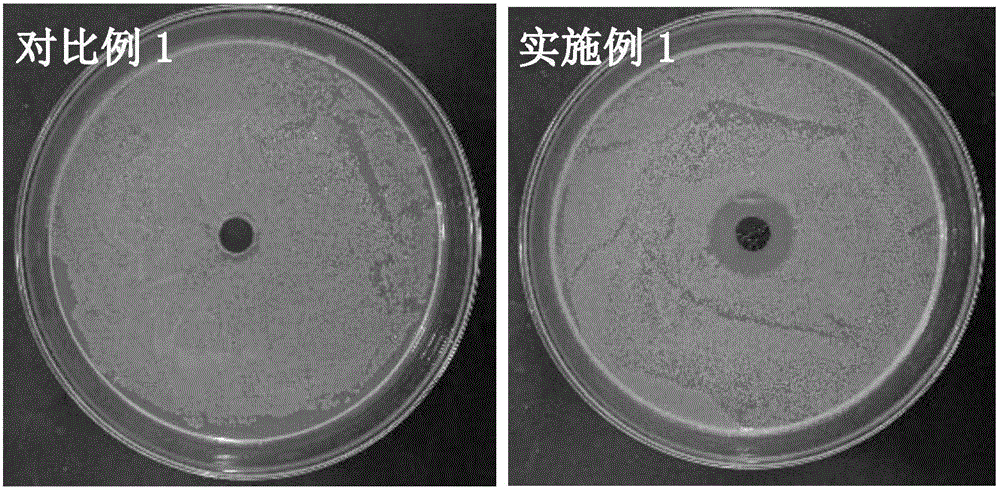

[0024] (1) Preparation of CNC and GO composite dispersion liquid CNC-GO: Mix CNC and GO water dispersion liquid according to the mass ratio of CNC and GO at 1:2, stir at room temperature for 10 min, and adjust the concentration of CNC-GO composite liquid with deionized water to 0.005g / mL, and then in a 100W ultrasonic cleaning machine, ultrasonically disperse for 30min to obtain a composite dispersion with a mass ratio of CNC and GO of 1:2, which is denoted as (CNC:GO-1:2);

[0025] (2) Preparation of PVA / CNC-GO composite membrane: 2g of PVA was stirred and dissolved in 25mL of deionized water at 90°C to obtain a uniform PVA aqueous solution; 12mL of the PVA / (CNC:GO obtained in the above step (1) -1:2) The composite dispersion liquid is added to the PVA aqueous solution, and stirred at 50°C for 20 minutes to obtain a PVA / 3% (CNC:GO-1:2) mixed solution; PVA / 3% (CNC:GO-1:2) ) the mixed solution was left to stand for defoaming and then poured into a glass mold, left at room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com