Tackifier copolymerization associate used for drilling fluid and preparation method of tackifier copolymerization associate

A technology of associates and viscosifiers, applied in the field of drilling fluid polymers and their preparation, can solve the problem of no obvious improvement in salt and calcium resistance, and achieve high temperature and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

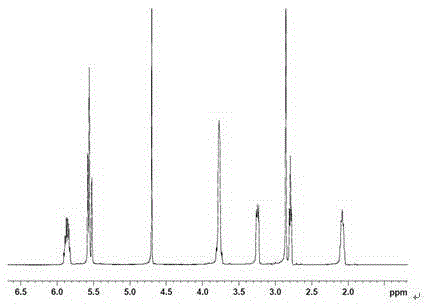

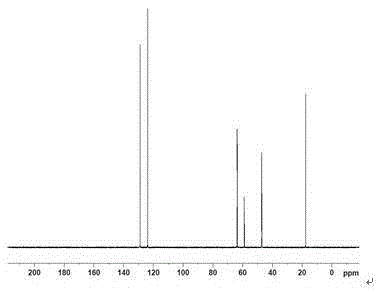

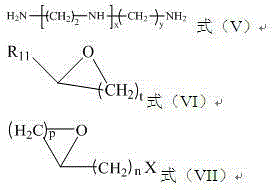

Method used

Image

Examples

Embodiment 1

[0068] Weigh 170g of MAPS, 140g of DMAM and 100g of cornstarch for later use, then weigh 6730g of deionized water and 1758g of NaCl to prepare NaCl solution, and divide the solution into two parts. Add cornstarch to a part of NaCl solution and gelatinize at 80°C for 30min, 2 After 30 min, 3.7 g of potassium persulfate was added, and then DMAM and MAPS were added to the remaining NaCl solution, dissolved and then transferred to gelatinized starch, and reacted at 65°C for 2 h to obtain an intermediate product. Then, 140 g of cationic polyamine 1 was dissolved in 300 g of deionized water to prepare a cationic polyamine solution, and then the cationic polyamine solution was added to the intermediate product, mixed evenly, and the temperature was raised to 75°C at the same time, and the reaction was continued for 4 hours. A precipitate was obtained by washing with acetone, and the precipitate was dried at 70° C. for 12 hours and then pulverized to obtain a grafted starch thickener....

Embodiment 2

[0070] Weigh 150g MAPS, 112g DMAM and 100g potato starch respectively for later use. Then weigh 2870g deionized water and 330g CaCl 2 Formulated as CaCl 2 solution, the solution was divided into two parts with a volume ratio of 6:4. Add potato starch to one more part of CaCl 2 The solution was gelatinized at 70°C for 30min, and N 2 After 30min, add 1.7g sodium persulfate, then add DMAM and MAPS to the remaining CaCl 2 After the solution was dissolved, it was transferred to a gelatinized starch reactor, and an intermediate product was obtained after reacting at 70° C. for 1.5 h. Then, 30 g of cationic polyamine 2 was dissolved in 100 g of deionized water to prepare a cationic polyamine solution, and then the cationic polyamine solution was added to the intermediate product, mixed evenly, and the temperature was raised to 80° C., and the reaction was continued for 3 hours. The precipitate was washed with acetone. The precipitate was dried at 80°C for 12 hours and then pulv...

Embodiment 3

[0072] Weigh 130g MAPS, 168g DMAM and 100g potato starch respectively for later use. Then weigh 1785g deionized water and 105g AlCl 3 Formulated as AlCl 3 solution, divide the solution into two equal parts. Add potato starch to a portion of AlCl 3 The solution was gelatinized at 60°C for 30min, and N 2 After 30min, add 5.3g ammonium persulfate, then add DMAM and MAPS to the remaining part of AlCl 3 After the solution was dissolved, it was transferred to a gelatinized starch reactor, and the intermediate product was obtained after reacting for 2 hours at 60°C. Then, 60 g of cationic polyamine 3 was dissolved in 200 g of deionized water to prepare a cationic polyamine solution, and then the cationic polyamine solution was added to the intermediate product, mixed evenly, and the temperature was raised to 70°C at the same time, and the reaction was continued for 4 hours. The precipitate was washed with acetone. The precipitate was dried at 80°C for 12 hours and then pulveriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com