Ion-bridged salt-tolerant polymer thickening agent as well as preparation method and application thereof

A polymer and thickener technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as high viscosity of fracturing fluid and difficulty in injection, improve temperature and salt resistance, reduce side effects, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of ion bridging salt-tolerant polymer thickener, comprising the following steps:

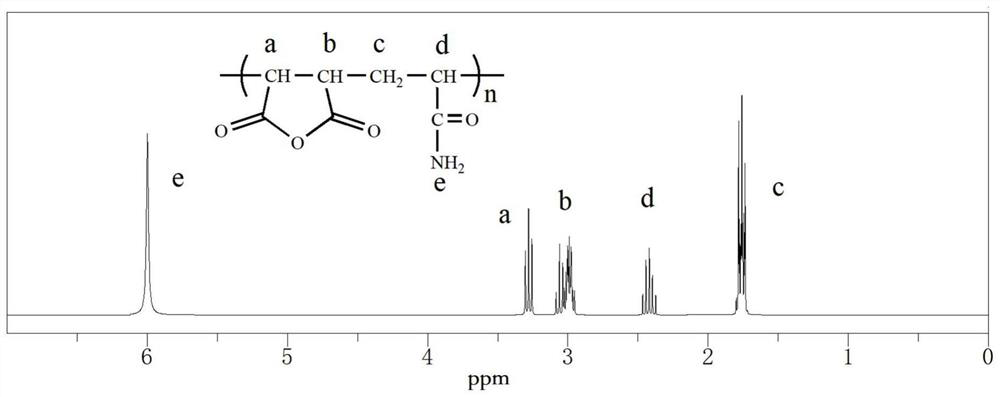

[0042] With 98.06g (1mol) maleic anhydride, 1.69g initiator azobisisobutyronitrile (1wt% of the mass sum of maleic anhydride and acrylamide) and 507.42 dimethylformamide (maleic anhydride quality and acrylamide 3 times of the sum of the masses) mixed, stirred continuously and heated to 80°C, added 71.08g (1mol) of acrylamide to react for 5h, after the reaction was complete, the solvent was distilled off under reduced pressure to obtain an ion bridging salt-tolerant polymer thickener, measured The obtained thickener molecular weight is 4827255, n=28540.

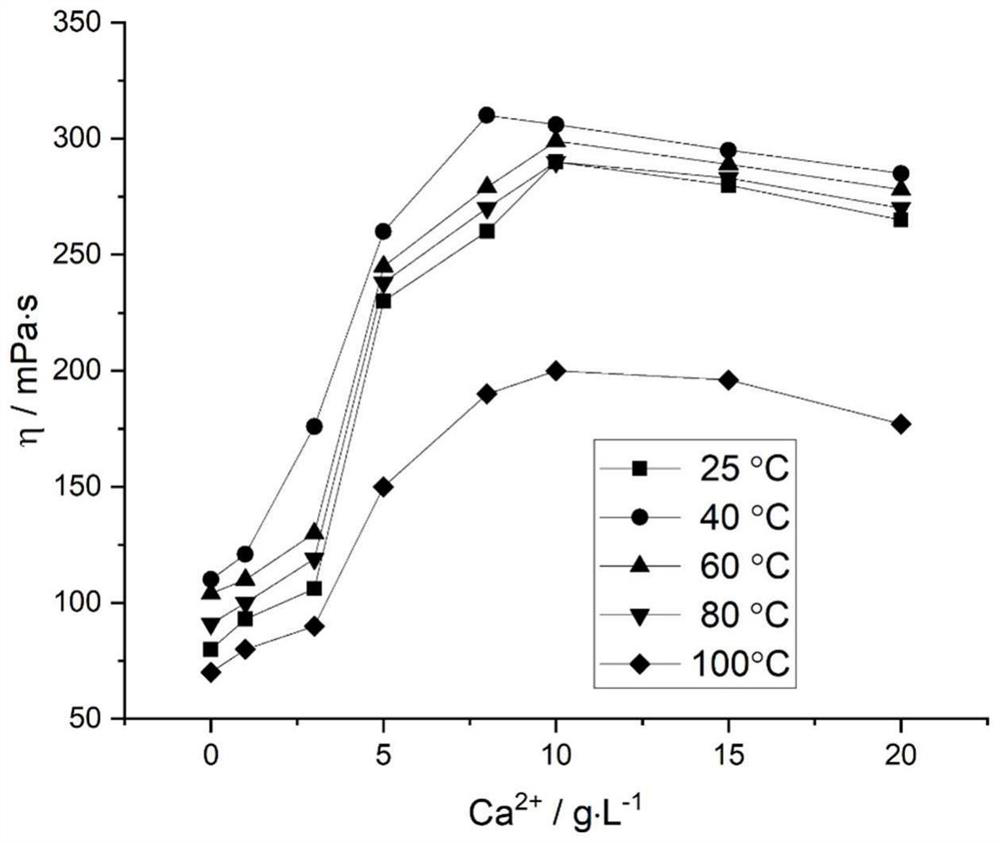

[0043] Dilute the obtained ion bridging salt-tolerant polymer thickener to 1.0wt% to carry sand, inject it into the bottom layer, and simulate the formation Ca 2+ , Mg 2+ Under the action of divalent ions, complexation, bridging and crosslinking are realized.

Embodiment 2

[0045] A preparation method of ion bridging salt-tolerant polymer thickener, comprising the following steps:

[0046] With 98.06g (1mol) maleic anhydride, 2.54g initiator azobisisobutyronitrile (1.5wt% of the mass sum of maleic anhydride and acrylamide) and 507.42 dimethylformamide (maleic anhydride quality and propylene 3 times the sum of the mass of amides) mixed, stirred continuously and heated to 75°C, added 71.08g (1mol) of acrylamide to react for 3h, after the reaction was complete, the solvent was distilled off under reduced pressure to obtain an ion bridging salt-tolerant polymer thickener. The measured molecular weight of the thickener is 3589150, n=21220.

[0047] Dilute the obtained ion bridging salt-tolerant polymer thickener to 0.8wt% sand-carrying agent, inject it into the bottom layer, and simulate the formation Ca 2+ , Mg 2+ Under the action of divalent ions, complexation, bridging and crosslinking are realized.

Embodiment 3

[0049] A preparation method of ion bridging salt-tolerant polymer thickener, comprising the following steps:

[0050] With 98.06g (1mol) maleic anhydride, 3.38g initiator azobisisobutyronitrile (2wt% of the mass sum of maleic anhydride and acrylamide) and 507.42 dimethylformamide (maleic anhydride quality and acrylamide 3 times of the sum of the masses) mixed, stirred continuously and heated to 80°C, added 71.08g (1mol) of acrylamide to react for 5h, after the reaction was complete, the solvent was distilled off under reduced pressure to obtain an ion bridging salt-tolerant polymer thickener, measured The obtained thickener molecular weight is 2650423, n=15670.

[0051] Dilute the obtained ion bridging salt-tolerant polymer thickener to 1.0wt% to carry sand, inject it into the bottom layer, and simulate the formation Ca 2+ , Mg 2+ Under the action of divalent ions, complexation, bridging and crosslinking are realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com