Preparation method for high-barrier water-resistant polyvinyl alcohol (PVA)/cellulose nanocrystal (CNC)/graphene oxide (GO) composite film

A technology of nanocrystalline cellulose and polyvinyl alcohol, which is applied in the field of polymer materials, can solve the problems of poor water barrier properties and decreased barrier properties, and achieve the effects of improving dispersibility, enhancing mechanical properties and processing properties, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of CNC aqueous dispersion: Disperse 1g of CNC in 200mL of deionized water, prepare a CNC solution with a concentration of 0.005g / ml, and disperse it ultrasonically for 30min in a 100W ultrasonic cleaning machine;

[0022] (2) Preparation of GO aqueous dispersion: Disperse 1 g of GO in 200 mL of deionized water, prepare a GO solution with a concentration of 0.005 g / mL, and ultrasonically disperse for 30 min in a 100W ultrasonic cleaner;

[0023] (3) Preparation of CNC and GO composite aqueous dispersion: Mix CNC and GO aqueous dispersion in the above steps (1) and (2) according to the mass ratio of 1:2, 1:1, 2:1, and stir at room temperature for 10 minutes , the concentration of the CNC and GO composite solution was obtained as 0.005g / mL, and then ultrasonically dispersed in a 100W ultrasonic cleaner for 30min to obtain composite dispersions with different mass ratios of CNC and GO;

[0024] (4) Preparation of PVA / CNC / GO composite solution: Dissolve 1g of...

Embodiment 2

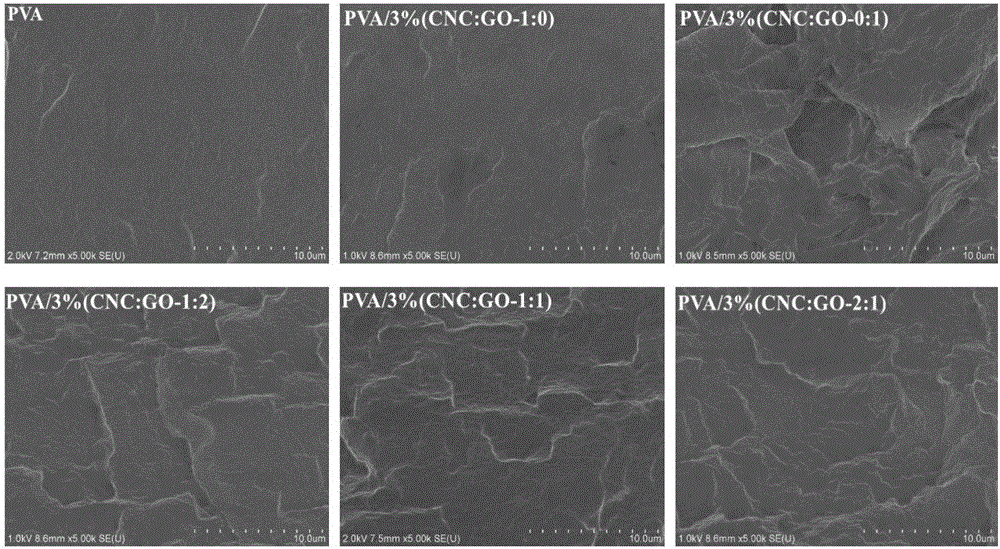

[0027] The scanning electron microscope (SEM) characterization was carried out under the S-4800 field emission scanning electron microscope, and the PVA and PVA / CNC / GO composite film samples to be observed were brittlely broken in liquid nitrogen to obtain the cross-section of the sample. After spraying gold on the sample, select a voltage of 2.0kV and a current of 10μA. Under different magnifications, observe the cross-section with a scanning electron microscope to obtain the SEM of the sample. figure 1 .

[0028] figure 1 It is the cross-sectional SEM image of PVA and PVA composite film. It can be seen from the figure that the cross-section of pure PVA film is relatively smooth without obvious wrinkles. From the SEM image of the fracture surface of the binary PVA / 3% (CNC:GO-1:0) composite film, it was found that there was no particle agglomeration, indicating that CNC was well dispersed in the PVA matrix. Comparing the SEM image of the cross-section of the PVA / 3% (CNC:GO-0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com