Graphene-oxide-modified phenolic-resin-based ultrafine porous carbon fiber and preparation method thereof

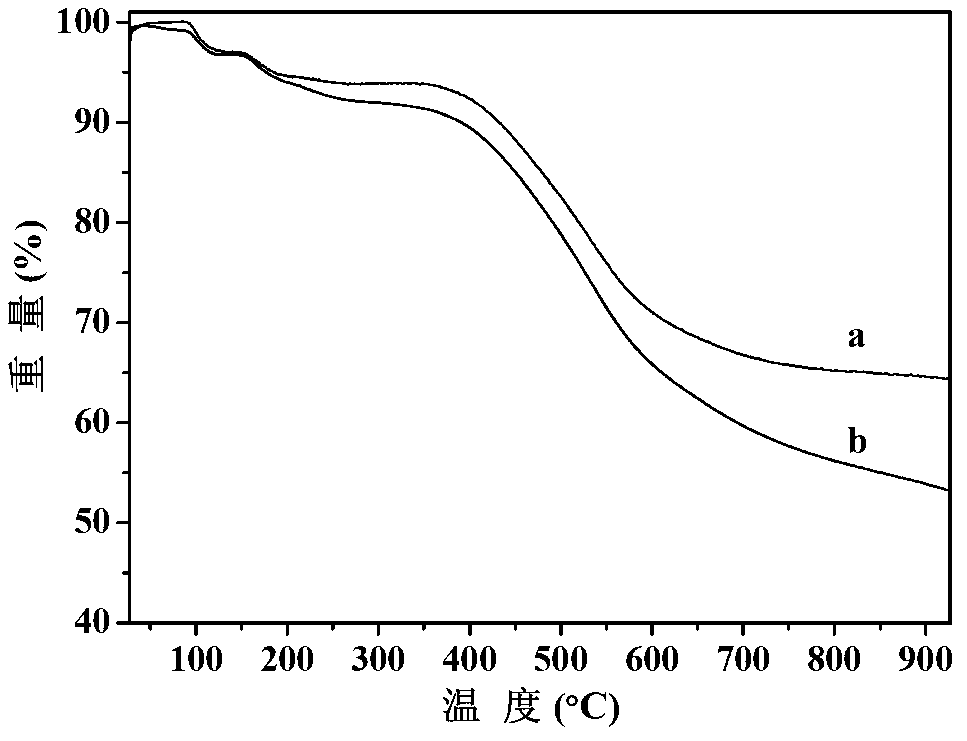

A technology of phenolic resin and graphene, applied in fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of low carbonization yield and low specific surface area of PAN fibers, and achieve improved flexibility, low preparation cost and improved thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment includes the following steps:

[0020] Step 1, adding graphene oxide into acetone, and ultrasonically dispersing to form a graphene oxide acetone solution with a concentration of 7.0 mg / ml;

[0021] Step 2, by thermosetting phenolic resin, polyvinyl butyral and graphene oxide mass ratio is the ratio of 1:0.020:0.03, thermosetting phenolic resin and polyvinyl butyral are added in graphene oxide acetone solution, will The mixed solution is stirred until completely dissolved, and the molecular weight of the thermosetting phenolic resin is 2000;

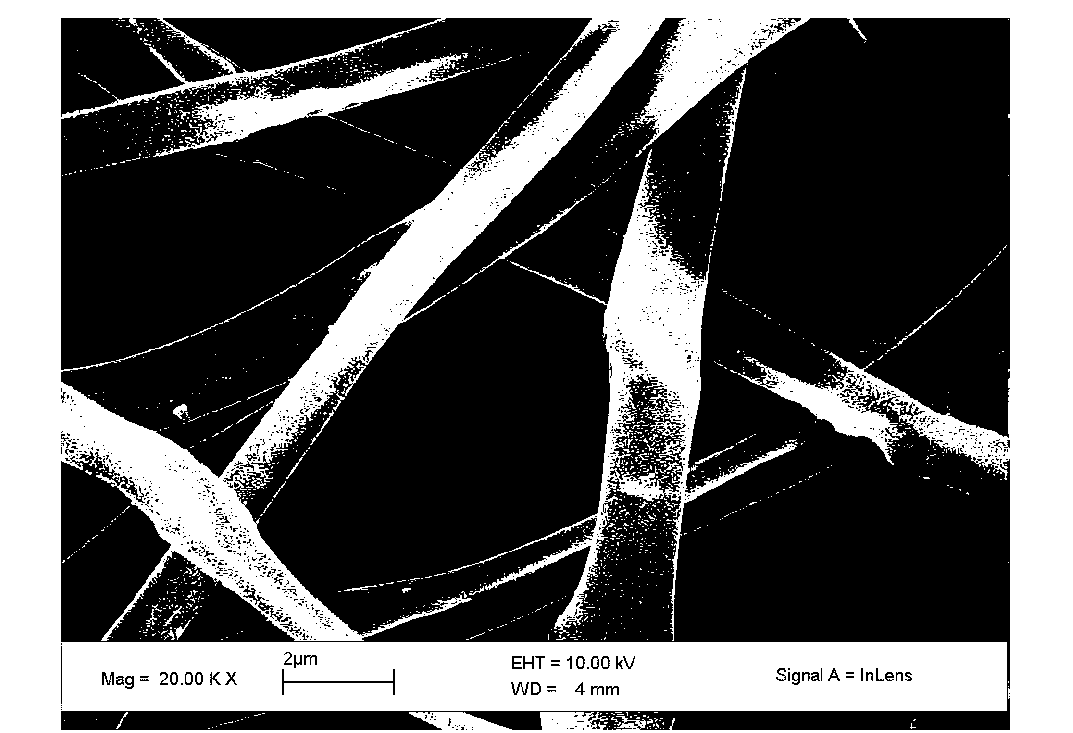

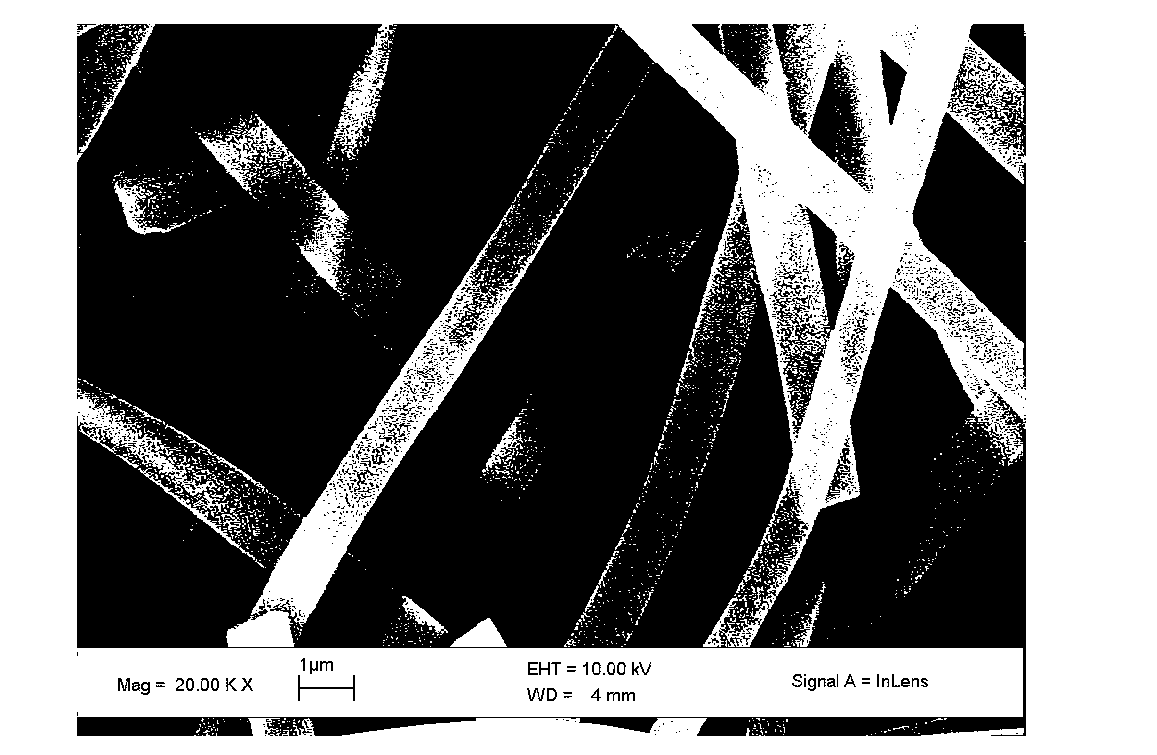

[0022] Step 3, electrospinning the mixed solution in step 2 into composite ultrafine fibers, the spinning voltage is 23kV, the liquid feeding speed is 1ml / h, and the working distance is 24cm;

[0023] Step 4: After the above-mentioned fiber is heated from room temperature to 180°C in a non-uniform stepwise manner, it is cured for another 2 hours. The rate should be lower than 4°C / h. As the temperature rises, the ...

Embodiment 2

[0026] This embodiment includes the following steps:

[0027] Step 1, adding graphene oxide into ethanol, and ultrasonically dispersing to form a graphene oxide ethanol solution with a concentration of 12.1mg / ml;

[0028] Step 2, according to the mass ratio of thermosetting phenolic resin, polyvinylpyrrolidone and graphene oxide is 1:0.024:0.05, adding thermosetting phenolic resin and polyvinylpyrrolidone to the graphene oxide ethanol solution, stirring the mixed solution Until completely dissolved, the molecular weight of the thermosetting phenolic resin is 2300;

[0029] Step 3, electrospinning the mixed solution in step 2 into composite ultrafine fibers, the spinning voltage is 25kV, the liquid feeding speed is 1ml / h, and the working distance is 22cm;

[0030] Step 4: After the above-mentioned fiber is heated from room temperature to 180°C in a non-uniform stepwise manner, it is then cured for 1.5 hours. The rate should be lower than 4°C / h. As the temperature increases, t...

Embodiment 3

[0033] This embodiment includes the following steps:

[0034] Step 1, adding graphene oxide into acetone, and ultrasonically dispersing to form a graphene oxide acetone solution with a concentration of 8.3 mg / ml;

[0035] Step 2, by thermosetting phenolic resin, polyvinyl butyral and graphene oxide mass ratio is the ratio of 1:0.018:0.02, thermosetting phenolic resin and polyvinyl butyral are added in graphene oxide acetone solution, will The mixed solution is stirred until completely dissolved, and the molecular weight of the thermosetting phenolic resin is 2000;

[0036] Step 3, electrospinning the mixed solution in step 2 into composite ultrafine fibers, the spinning voltage is 25kV, the liquid feeding speed is 1ml / h, and the working distance is 24cm;

[0037] Step 4: After the above-mentioned fiber is heated from room temperature to 180°C in a non-uniform stepwise manner, it is cured for another 2 hours. The rate should be lower than 4°C / h. As the temperature rises, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com