Patents

Literature

102results about How to "Adapt to large-scale industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

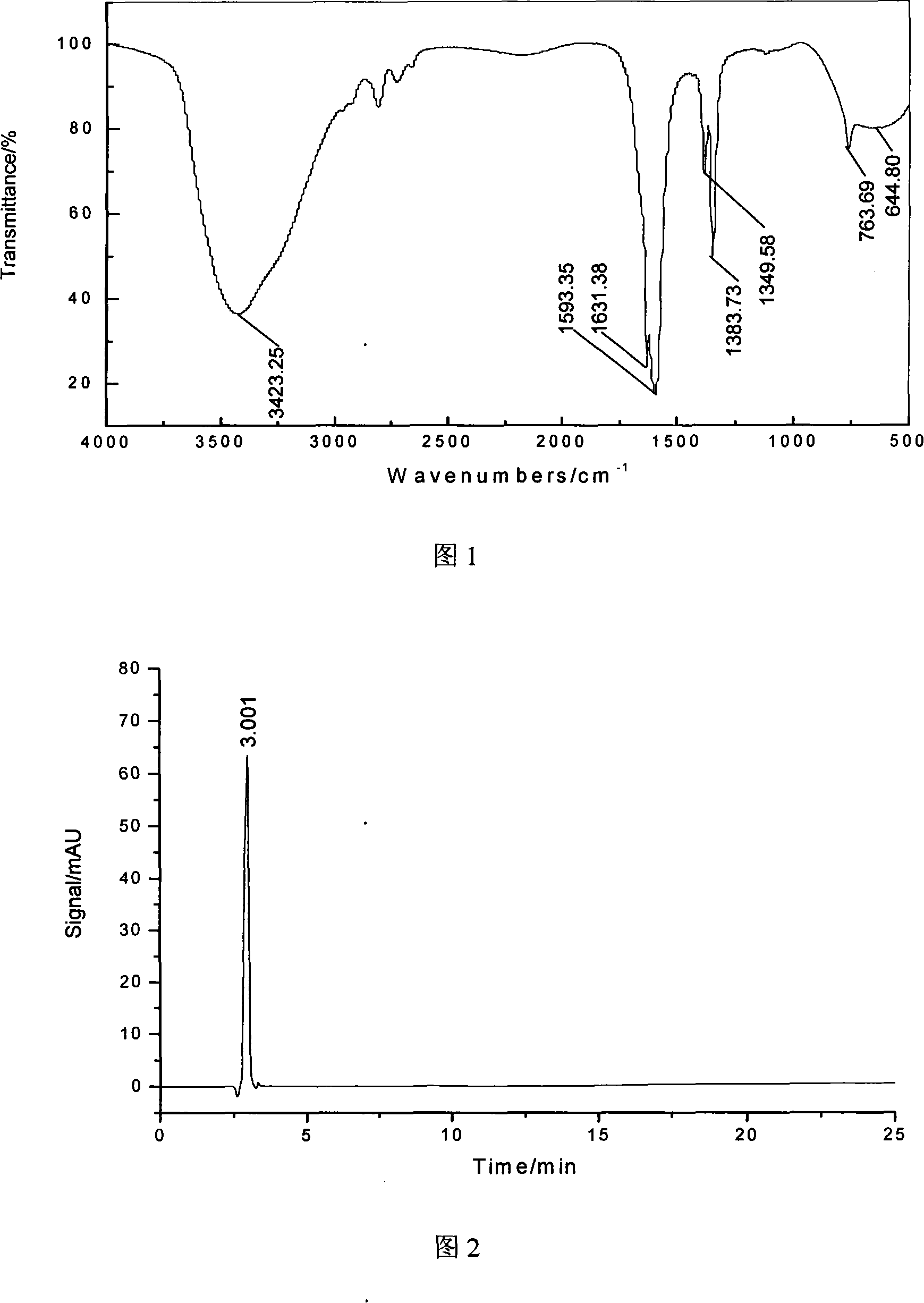

Method for preparing peanut protein composite fiber by using ionic liquid

InactiveCN102586942ADissolve fastReduce solubilityConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentHigh concentrationStrong acids

The invention discloses a method for preparing a peanut protein composite fiber by using ionic liquid. The method comprises the following steps of: dissolving peanut protein and polyvinyl alcohol in imidazole ionic liquid respectively to obtain a peanut protein ionic liquid solution and a polyvinyl alcohol ionic liquid solution; mixing the peanut protein ionic liquid solution and the polyvinyl alcohol ionic liquid solution in a mixed ratio of 1:3-1:5; adding an aid to obtain a spinning solution, and entering a coagulating bath; preparing a peanut protein / polyvinyl alcohol composite fiber by awet spinning method in the coagulating bath; and stretching, washing, performing acetal treatment, applying oil, drying, curling, sizing, and thus obtaining the mixed fiber. By the method, the ionic liquid instead of strong acid and strong alkali is used as a solvent in the process of synthesizing a peanut protein fiber, so that the peanut protein and the polyvinyl alcohol can be quickly dissolved at high concentration and a low temperature, and the preparation process is non-toxic and pollution-free at the same time.

Owner:SHANDONG PEANUT RES INST +1

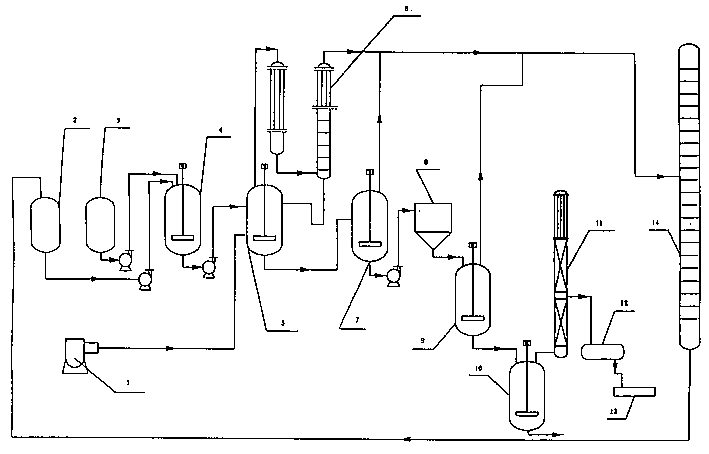

Process for production of trimellitic anhydride by continuous oxidizing process

A process for preparing trimellitic anhydride from metatritoluene, acetic acid as solvent, and catalyst (cobalt acetate, manganess acetate, tetrebromoethane, or hydrogen bromide) by continuous oxidization method includes continuous oxidizing reaction, anhydridization, refining, slicing or granulating and recovering solvent. Its advantages are high yield (up to 120%), high safety, high quality of product, and long service life of equipment.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

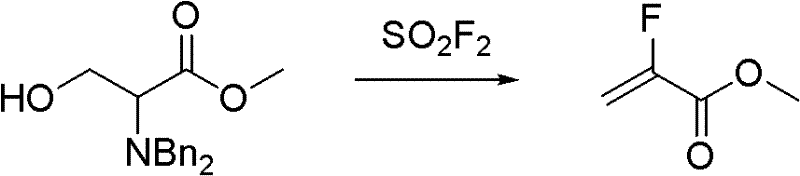

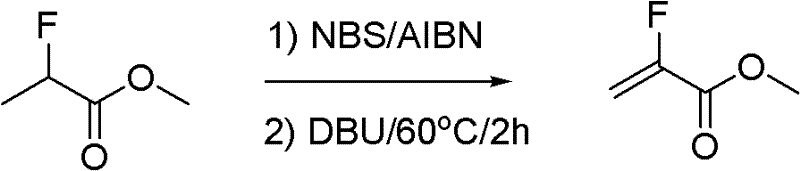

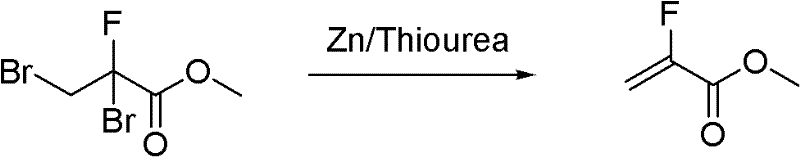

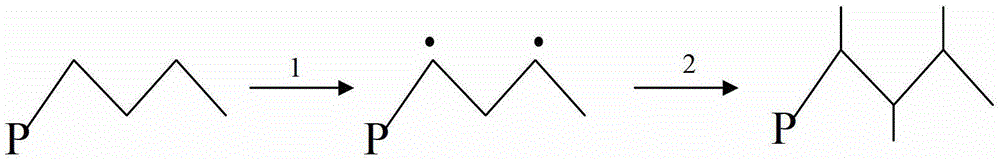

Synthesis method of methyl-alpha-fluoroacrylate and analogues thereof

InactiveCN102211998ALow costReduce manufacturing costOrganic compound preparationCarboxylic acid esters preparationSynthesis methodsSolvent

The invention relates to a synthesis method of methyl-alpha-fluoroacrylate and analogues thereof. The method comprises the following steps: step 1, based on methyl fluoroacrylate and dimethyl oxalate serving as raw materials, dissolving the raw materials in a solvent, and adding base for carrying out condensation reaction so as to generate sodium enolate or potassium enolate intermediate; and step 2, reacting sodium enolate or potassium enolate intermediate with paraformaldehyde or trioxane in the solvent so as to generate methyl-alpha-fluoroacrylate. According to the invention, cheap methyl fluoroacrylate and dimethyl oxalate are used as the raw materials, and the low-cost solvent and other reactants are selected, thus the method has the advantages of low preparation cost and high yield and can be suitable for large-scale industrial production.

Owner:RADIANT PHARMA & TECH

Acanthopanax senticosus effective fraction extract, preparation and application thereof

InactiveCN101214270ASimple and efficient operationReduce environmental pollutionNervous disorderImmunological disordersSoursop extractChemistry

The present invention discloses an extract of acanthopanax effective part, a preparation method thereof and an application thereof. In the acanthopanax extract of the present invention, total glycoside takes 20 to 64wt percent of the gross extract; total flavone takes 20 to 65wt percent of the gross extract; total glycoside total flavone takes 50 to 90wt percent of the gross extract. The preparation method of the acanthopanax effective part of the present invention is simple and convenient and causes little environmental pollution; the extracting and separating carrier can be used repeatedly for a plurality of times; the present invention has low cost and is applied to mass industrialization production.

Owner:HARBIN RENHUANG PHARMA

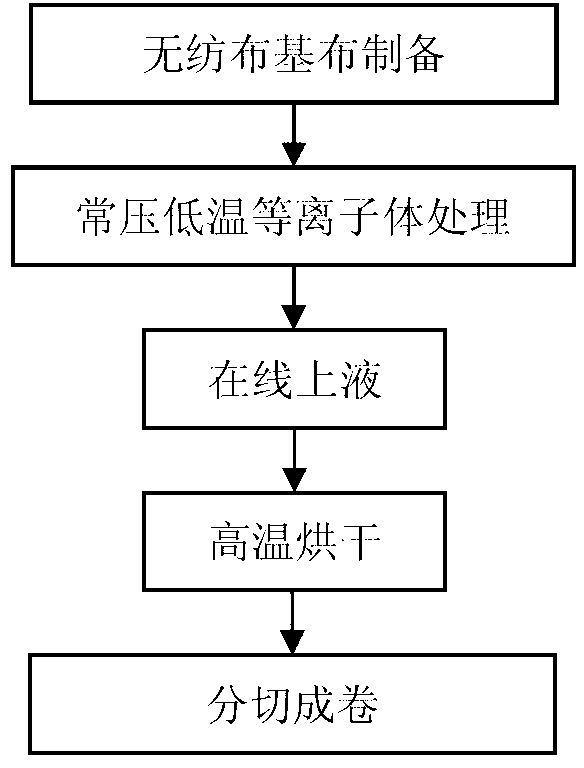

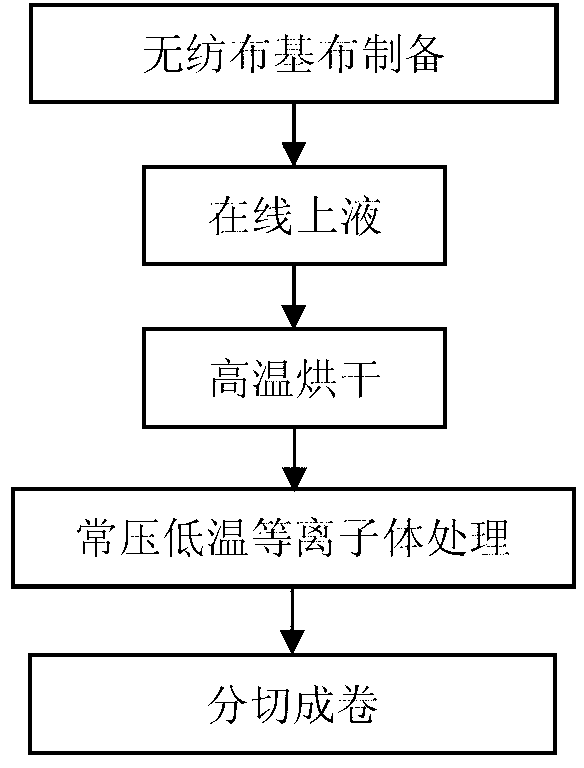

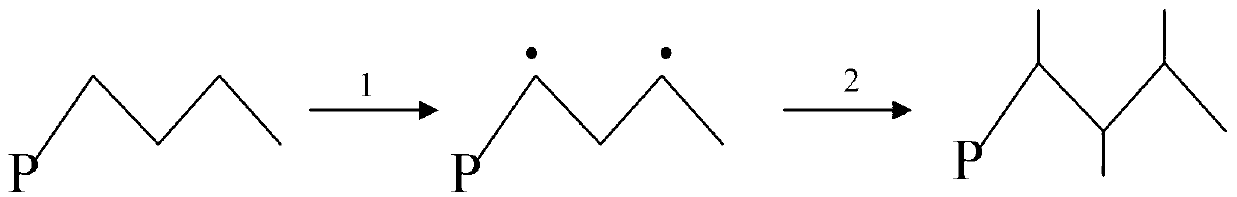

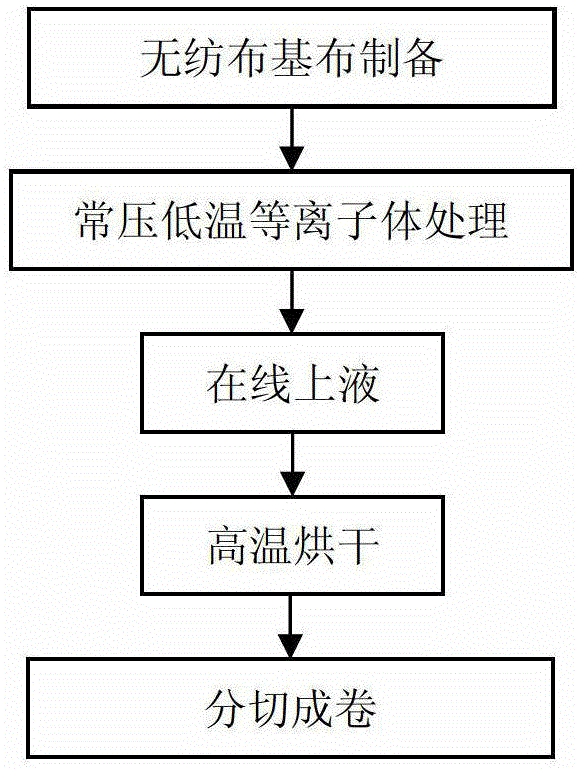

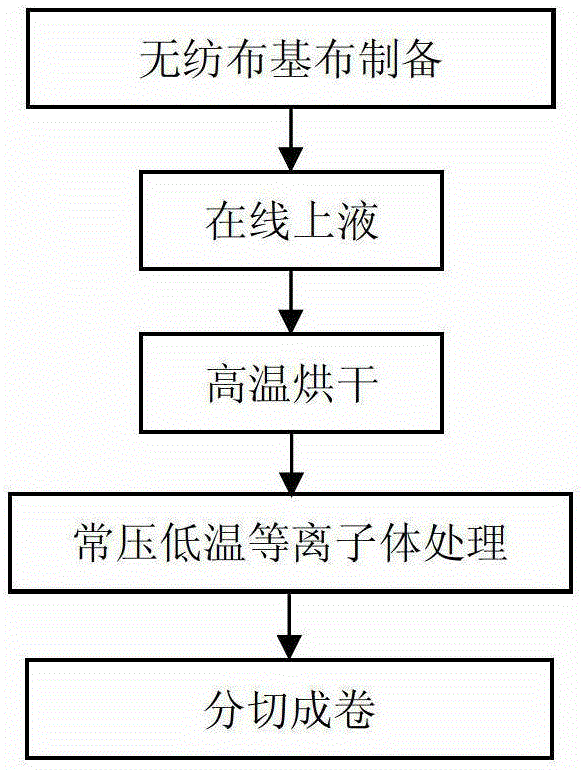

Finishing method for non-woven fabrics with high isolation performance and materials of non-woven fabrics with high isolation performance

ActiveCN102995400ALittle impact on air permeabilityReduce consumptionFibre treatmentAlcoholEngineering

The invention relates to a finishing method for non-woven fabrics with high isolation performance and materials of the non-woven fabrics with the high isolation performance. The finishing method combines on-line liquid feeding and normal-pressure low-temperature plasma processing, carries out normal-pressure low-temperature plasma processing before or after on-line liquid feeding, and forms a fluorine-containing polymer layer on the surface of the non-woven fabrics, so as to realize high isolation performance. The invention provides the finishing method for the non-woven fabrics which is novel, simple in process and good in finishing effect. Compared with the traditional saturated steeping, the finishing method has small influences on the non-woven fabrics, is high in production efficiency and has low energy consumption; compared with the existing plasma processing method, vacuum conditions are not needed, on-line liquid feeding is directly carried out, and low-temperature plasma processing is directly carried out under normal pressure, and other additional equipment conditions are not needed; and the contact angle between the prepared non-woven fabrics with high isolation performance and water can reach 120-160 degrees, and the prepared non-woven fabrics with high isolation performance has good air permeability and soft and comfortable feel, can reach requirements for resisting alcohol, oil and blood of each industry, and can well meet the large-scale industrial production.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

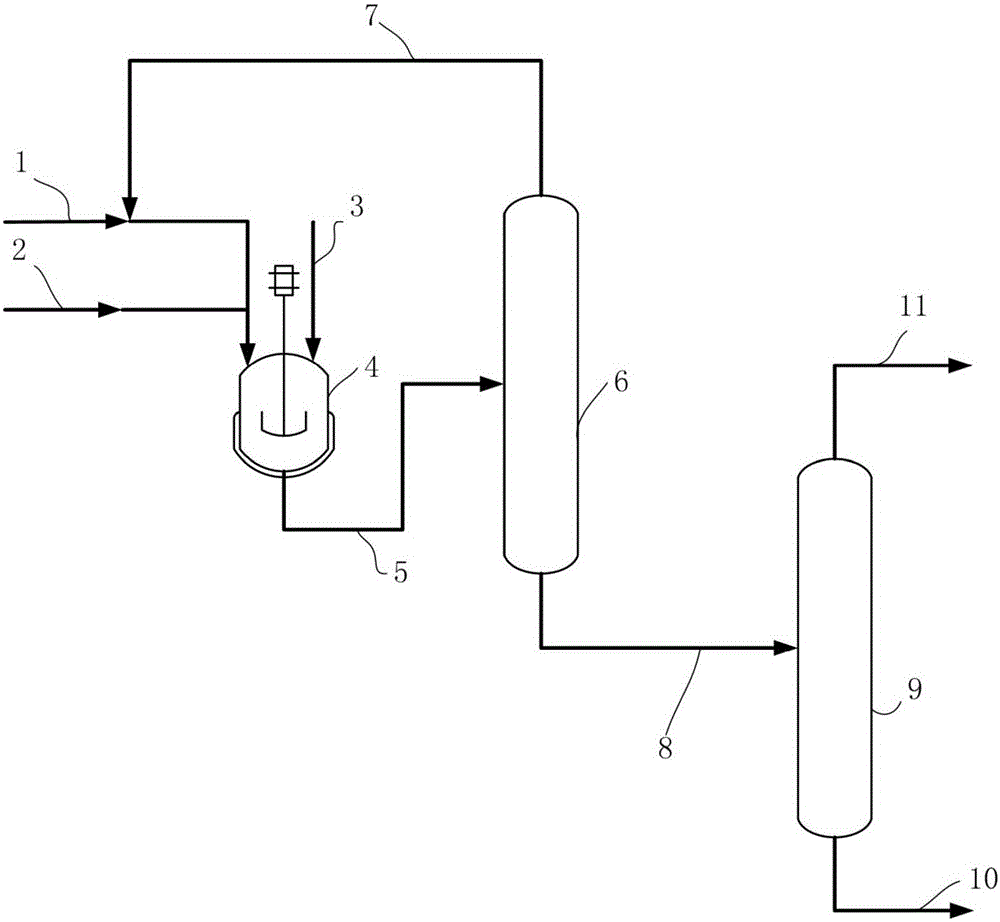

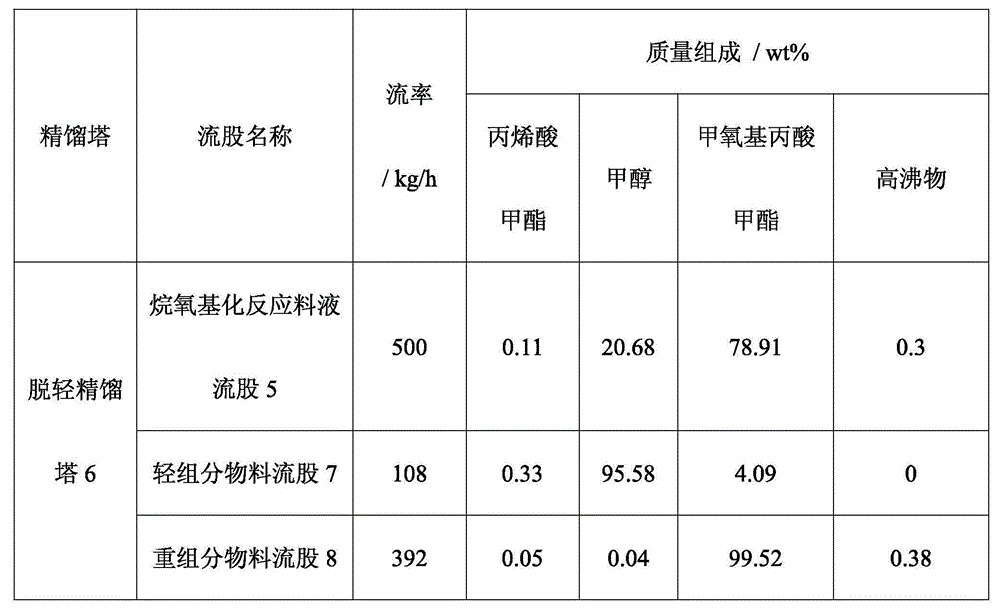

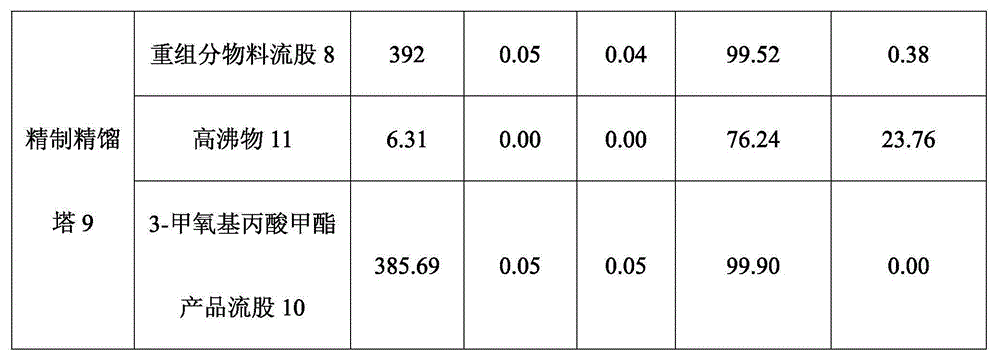

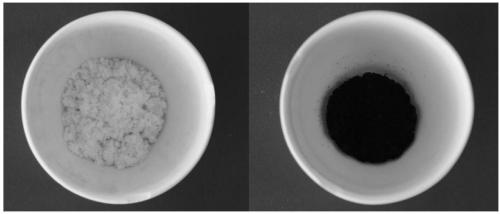

Preparation method of 3-alkoxy alkyl propionate

ActiveCN105037151AConvenient amountOptimizationOrganic compound preparationCarboxylic acid esters preparationChemical synthesisPropionate

The invention belongs to the technical field of chemical synthesis and provides a preparation method of 3-alkoxy alkyl propionate. The method is characterized by using solid alkali as a catalyst and alkyl acrylate and lower alcohol as raw materials to carry out heterogeneous catalytic alkoxylation reaction, and comprises the steps that an alkoxylation reaction product enters a light component removal rectifying tower to be separated, and lower alcohol and an alkyl acrylate light component, which are recovered from the tower top, are cycled into the step of alkoxylation reaction; a heavy component mainly containing a product 3-alkoxy alkyl propionate is obtained in a tower reactor; the heavy component material in the light component removal rectifying tower reactor is separated by a refined rectifying tower, the product 3-alkoxy alkyl propionate is obtained at the tower top and a few high-boiling substances are obtained in the tower reactor. The preparation method has the beneficial effects that after being separated and recovered by the rectifying tower, the used raw materials and solid alkali serving as the catalyst can be directly put into reaction again without being reprocessed, thus greatly improving the utilization efficiency of the raw materials and the catalyst, reducing the production cost and avoiding environmental pollution.

Owner:南京资环工程技术研究院有限公司

Preparation method of radiation-proof cement clinker mineral phase system

The invention discloses a preparation method of a radiation-proof cement clinker mineral phase system, which comprises the following steps of: (1) raw material preparation: raw materials are uniformly mixed according to a ratio, and are ground until the amount of residues on a 180-mesh square hole sieve is less than or equal to 10%; and (2) high temperature sintering: the ground powder in the step 1 is pressed into cylindrical test pieces, and the cylindrical test pieces are placed in a corundum crucible and are calcinated for 1 to 3 hours at a high temperature in a reheating test furnace to obtain the desired mineral phase system. The raw materials are calcium carbonate, alumina, and boron oxide, or calcium carbonate, alumina, boron oxide, and iron oxide. Through the mineral phase systemprepared by the preparation method disclosed by the invention, neutrons can be absorbed, the heat consumption of a cement clinker preparation process is reduced, the normal setting and hardening of cement are promoted, the strength of cement is improved, the mass concrete cracks can be inhibited, and the durability of concrete is improved. The method provided by the invention is simple in process, is easy to control and adapts to large-scale industrial production.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

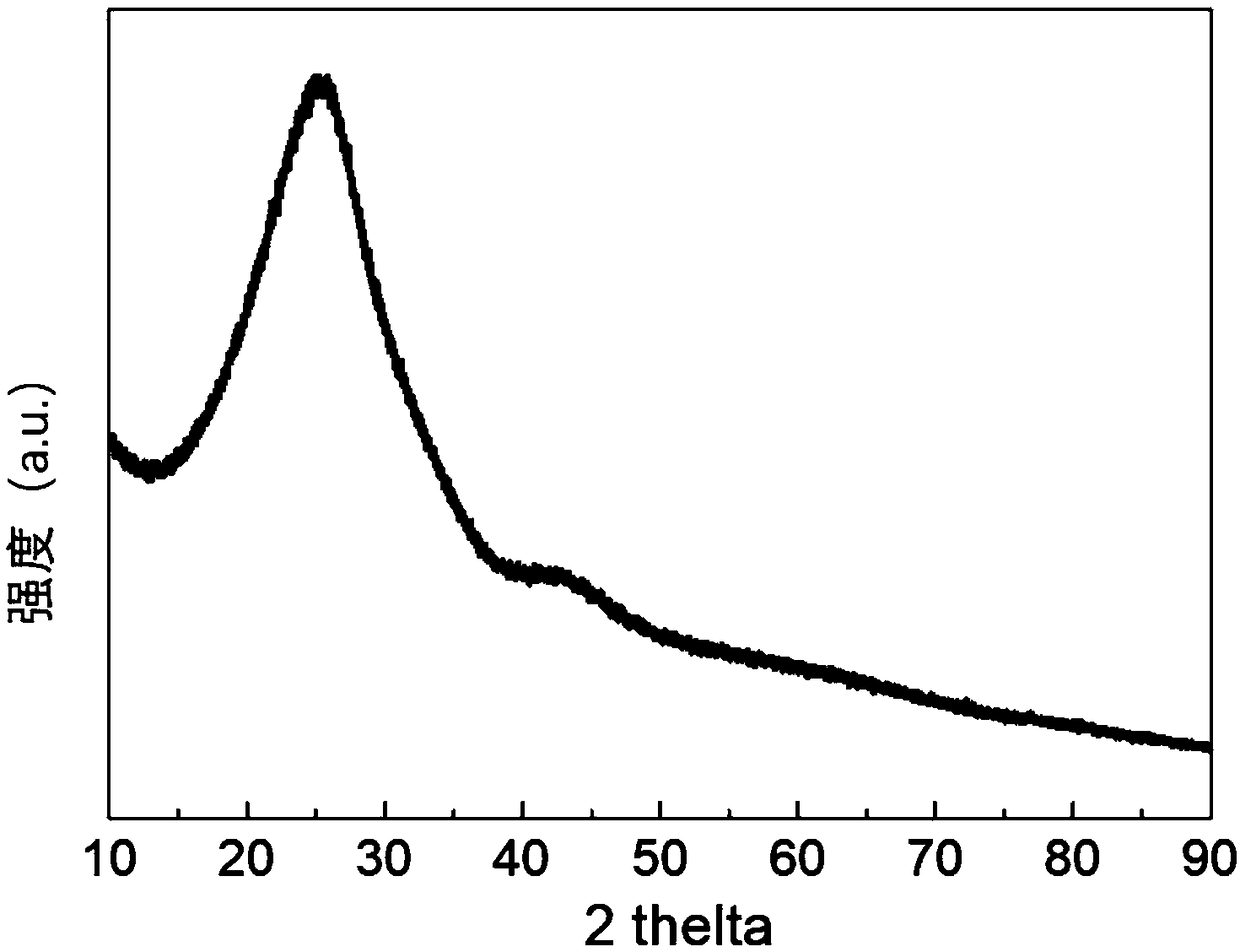

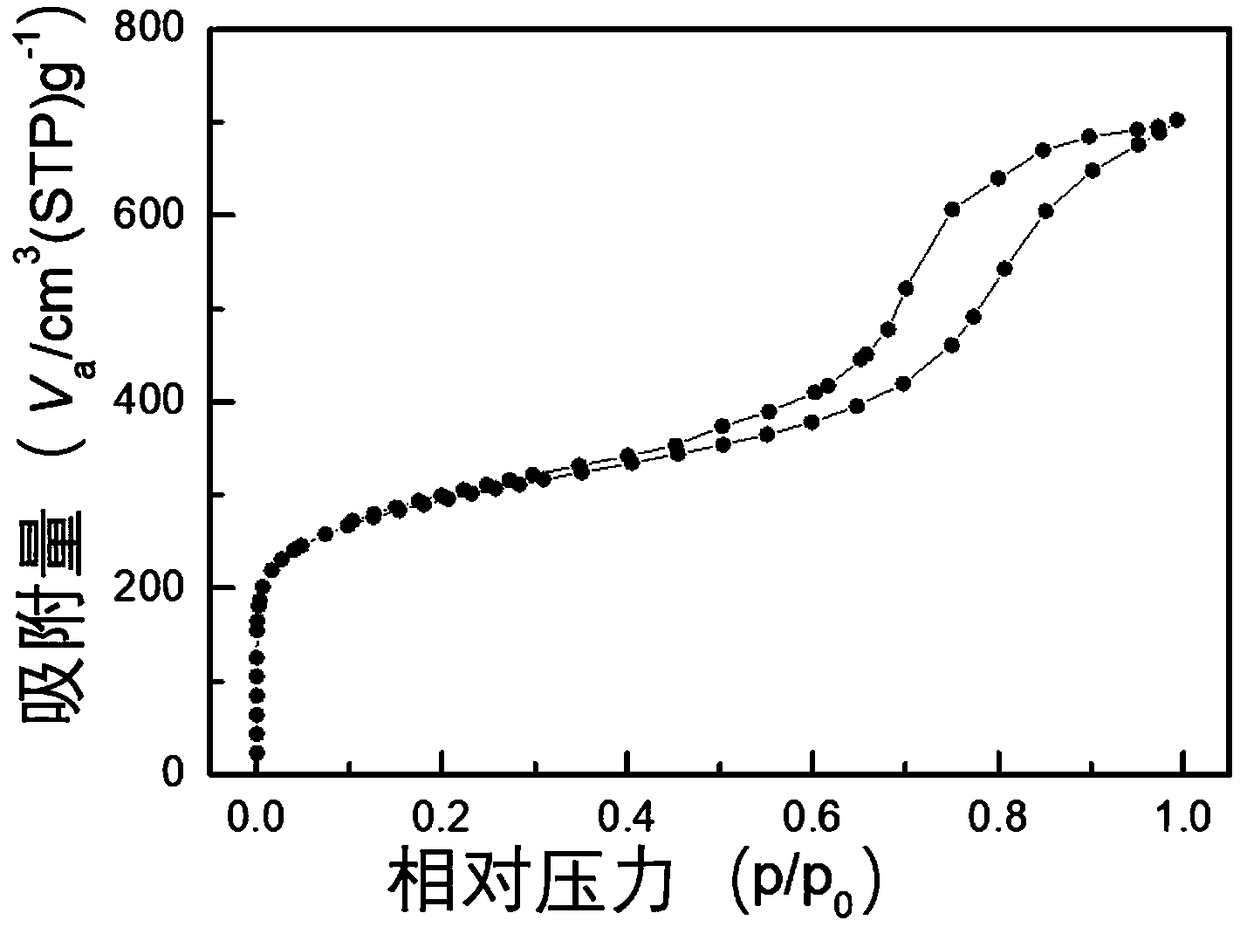

Carbon material preparation method

InactiveCN109081325AReaction conditions are easy to controlEasy to prepareCarbon preparation/purificationBulk chemical productionAir atmosphereCarbonization

The invention discloses a carbon material preparation method which is characterized in that a precursor is placed into a crucible or a container with a crucible function and covered with a crucible cover, the precursor and the crucible or the container are placed into a muffle furnace or a similar muffle furnace environment, the precursor is directly carbonized at high temperature, insulated for aperiod of time at the carbonization temperature, cooled to room temperature and finally washed and dried to obtain a needed carbon material. High-temperature carbonization is directly performed in air atmosphere in the muffle furnace, reaction conditions are easily controlled, severe conditions such as a tubular furnace and inert gases such as argon or nitrogen are omitted, the preparation methodis simple, fewer in steps, strong in operability, easy in amplification preparation and adaptable to large-scale industrial production. The nitrogen-oxygen doped mesoporous carbon material prepared by the method is high in specific surface area, large in pore volume, narrow in mesoporous size distribution, strong in hydrophily and stably dispersed in water.

Owner:HUNAN UNIV

Rapid propagation method for holcoglossum flavescens

ActiveCN104996301ASolve protection problemsSolve the problems of industrial development and applicationPlant tissue cultureHorticulture methodsGrowth coefficientHolcoglossum

The invention discloses a rapid propagation method for holcoglossum flavescens. Rapid propagation of holcoglossum flavescens is completed through the steps of seed germination, induction of protocorm, differentiation culture, strong seedling culture, rooting culture, acclimatization and transplant and the like. Compared with a traditional division method, the growth coefficient of holcoglossum flavescens is improved by more than 5 times, the planting percent reaches 95%, the survival rate of transplanting reaches more than 85%, meanwhile, the method has the advantages of being large in increment coefficient, strong in tillering capacity, high in growth speed, strong in plant, low in browning ratio, high in survival rate of transplanting, and low in cost, culture medium is easy to prepare, and the method can be applied to large scale industrial production.

Owner:FLOWER RES INST OF YUNNAN ACAD OF AGRI SCI

Solvent-free heating-free method for synthesizing potassium diformate

InactiveCN101125809ASave energyReduce lossesCarboxylic acid salt preparationSynthesis methodsPotassium

A non-solvent and non-heating method for synthesizing potassium diformate relates to a compound preparation method, which is a one-step potassium diformate synthesis method that takes potassium hydroxide and formic acid as raw materials and requires no solvent and no heating. A normal atmospheric pressure refluxing reaction method is adopted, and the solid potassium hydroxide is added into the formic acid by a molar ratio of 1:2.0-3.0 between the solid potassium hydroxide and the formic acid; the reaction temperature is kept between 50-90 DEG C when the materials are added; the reaction continues when the materials adding stops and is not stopped until the temperature falls to 20-50 DEG C; the reaction product is cooled and crystallized at room temperature, and the crystallized product is dried at a temperature of 50-60 DEG C and finely grinded, then the potassium diformate is acquired. No heating is required in the reaction, thereby the reaction intensity is well controlled while the reaction heat is fully utilized; the product is synthesized without solvent, thereby saving the evaporating and concentrating processes, shortening the production period and improving the production efficiency; the yield of the potassium diformate is as high as 99 percent or over. The method is suitable for large scale industrial production.

Owner:XIAMEN UNIV

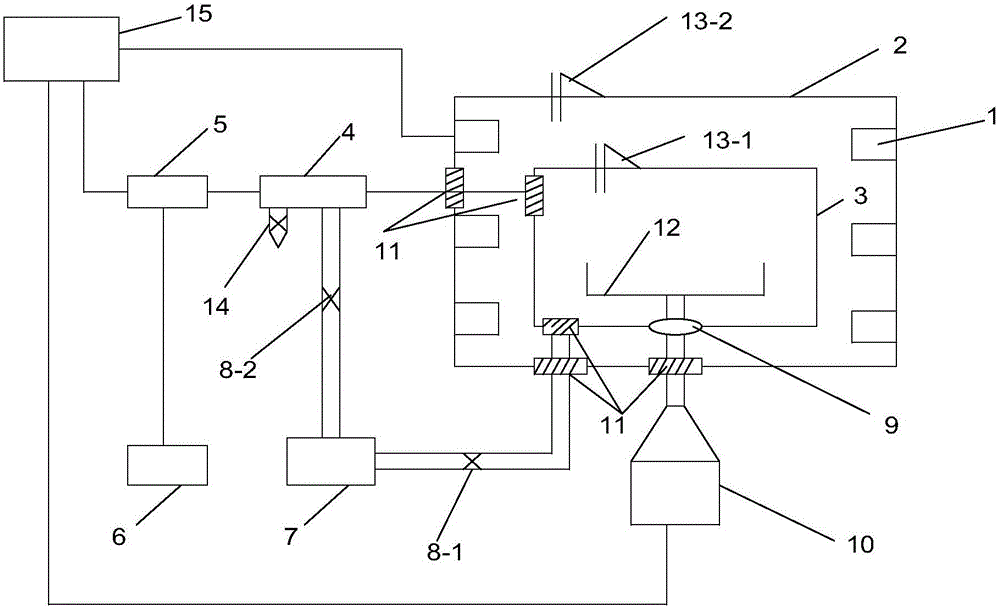

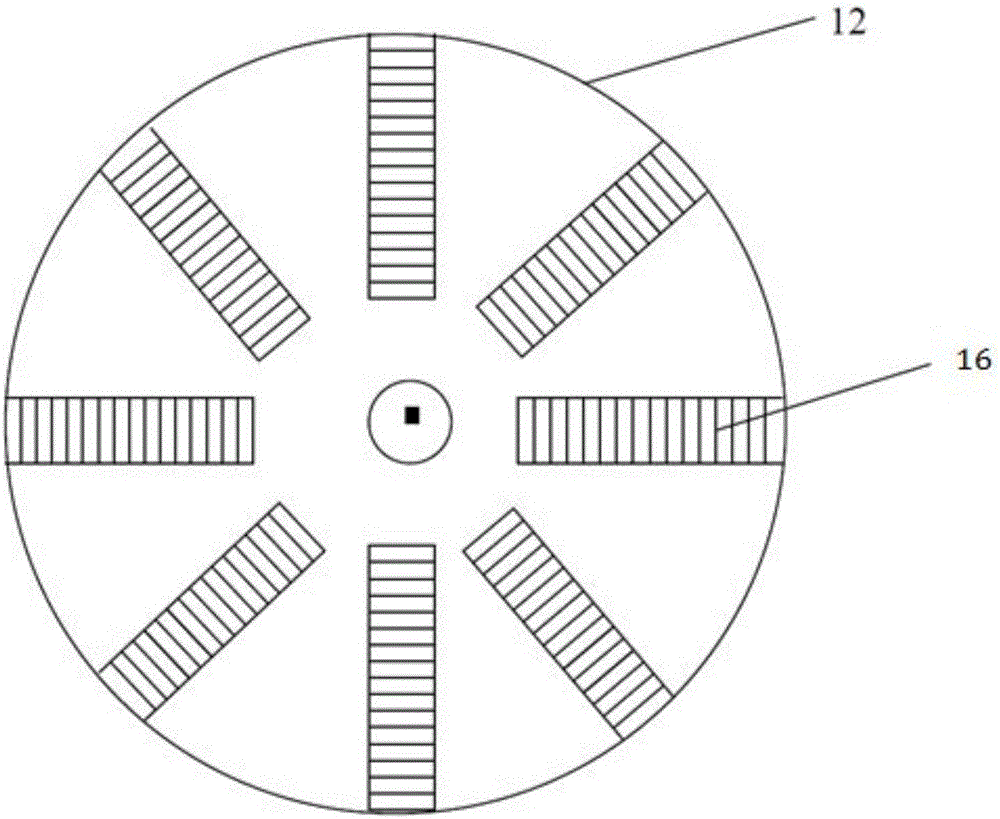

Microwave vacuum freeze drying equipment and material drying method

ActiveCN106839661AEfficient dryingHeating evenlyDrying solid materials without heatControl systemFreeze-drying

The invention provides microwave vacuum freeze drying equipment and an aerogel material drying method. The microwave vacuum freeze drying equipment comprises a microwave cabin, a freeze drying cabin, microwave generators of which the transmitting power can be continuously adjusted, a refrigerating system, a vacuum water-catching system, a pressure adjusting system, a vacuum pump and a micro-computer central control system, wherein the freeze drying cabin is arranged in the microwave cabin; the microwave generators of which the transmitting power can be continuously adjusted are fixed to the side wall of the microwave cabin and are uniformly and crossly arranged around the freeze drying cabin; the refrigerating system is connected with the freeze drying cabin and the vacuum water-catching system; the vacuum water-catching system is connected with the vacuum pump and the freeze drying cabin; the pressure adjusting system is connected with the vacuum pump and the freeze drying cabin; the pump is connected with the freeze drying cabin; and the micro-computer central control system is connected with the microwave generators and the pressure adjusting system so as to control microwave power and pressure.

Owner:优澎(嘉兴)新材料科技有限公司

Water-based nano high-coverage 3D printing coating and preparation method thereof

InactiveCN107057028AIncrease coverageIncrease elasticityAdditive manufacturing apparatusDyeing processWater basedChemistry

The invention provides a water-based nano high-coverage 3D printing coating which is prepared from water-based polyurethane resin, water-based nanoscale color paste, ionized water and propylene glycol at the mass ratio of (75-90):(6-10):(9-11):(1-3), wherein the solid content of the water-based polyurethane resin is 50-60%; and the fineness of the water-based nanoscale color paste is 85-100nm. The preparation method of the water-based nano high-coverage 3D printing coating comprises the main steps of preparing the water-based polyurethane resin and the water-based nanoscale color paste separately, and then fully mixing the water-based polyurethane resin, the water-based nanoscale color paste, the ionized water and the propylene glycol at the mass ratio; and adding a polyurethane thickening agent for viscosity control to prepare the water-based nano high-coverage 3D printing coating. The water-based nano high-coverage 3D printing coating has the characteristics of high coverage rate, high elasticity and high third dimension, can adapt to the diversity of printing materials, and is relatively low in production cost and suitable for large-scale industrial production, therefore, the water-based nano high-coverage 3D printing coating has potential market values and wide application prospects.

Owner:深圳凯奇化工有限公司

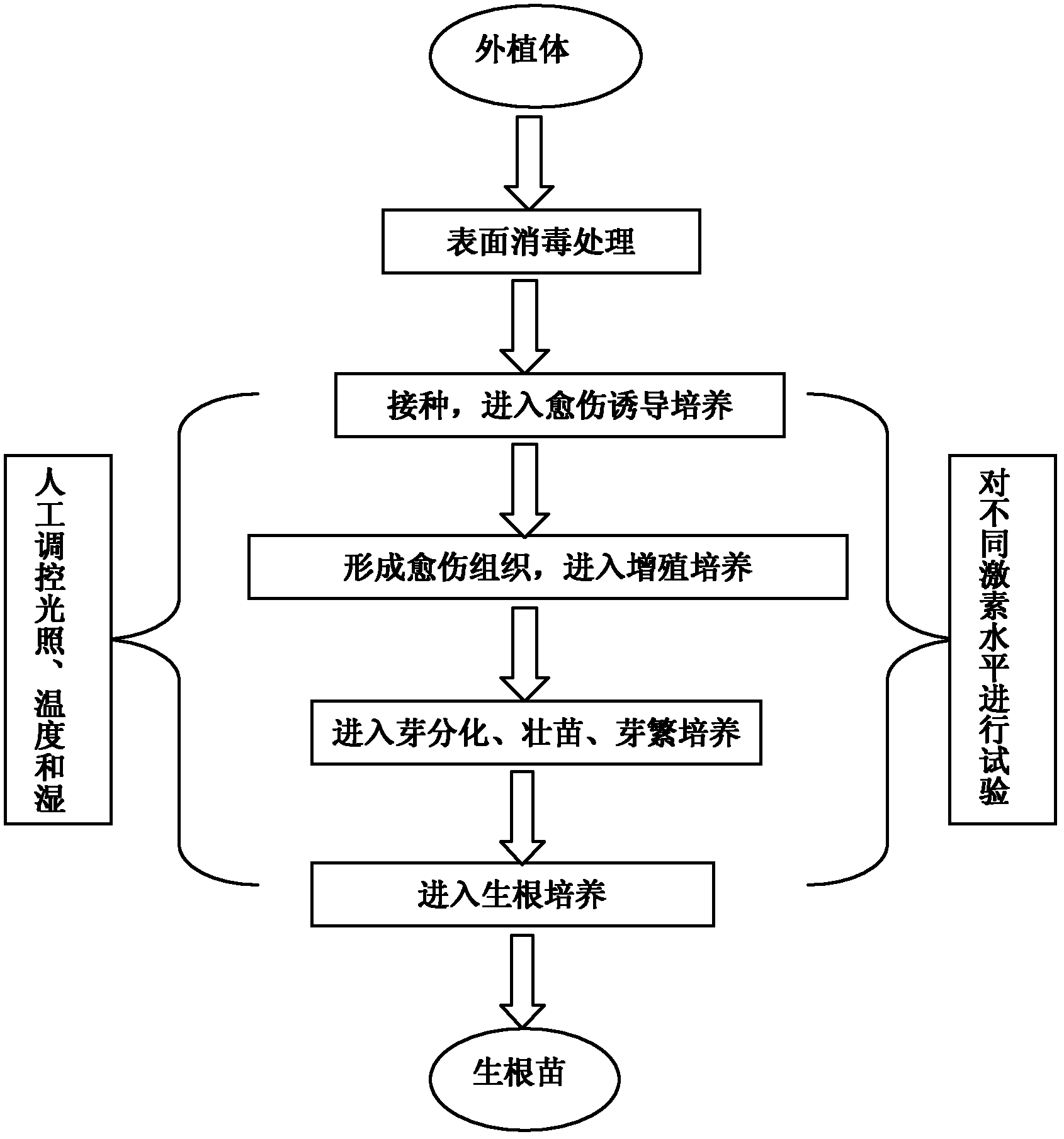

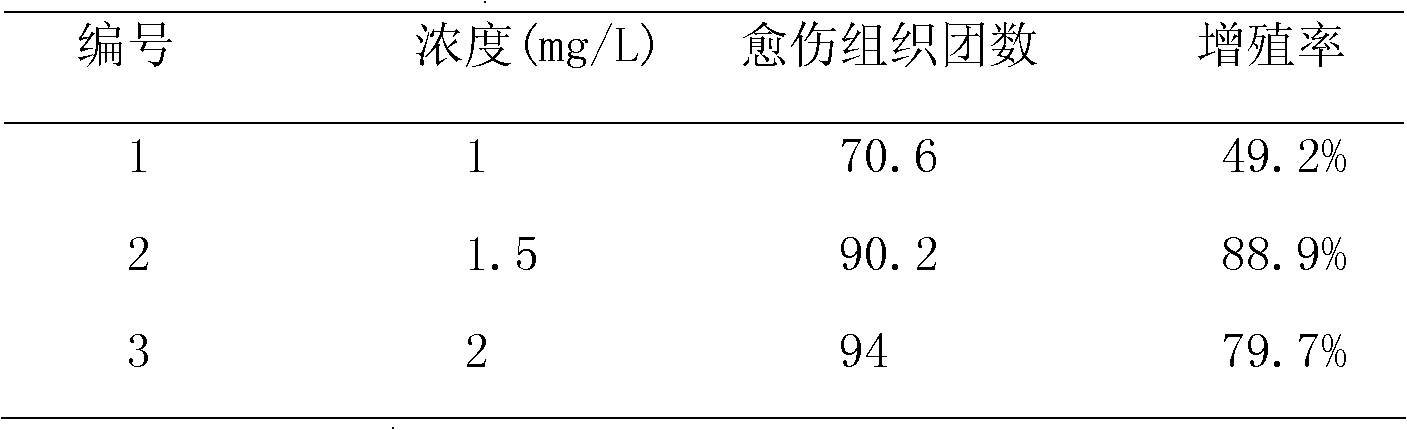

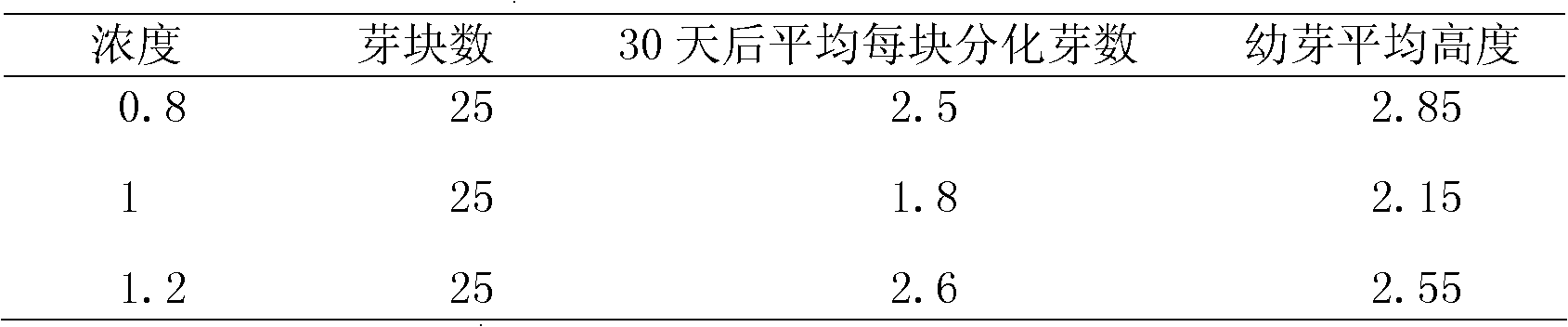

Method for tissue culture of hoya kerrii

InactiveCN102577972AGuaranteed to be uniformEasy to transplantHorticulture methodsPlant tissue cultureAdditive ingredientSeedling

The invention relates to a method for tissue culture of a plant, in particular to a method for tissue culture of hoya kerrii, which belongs to the technical field of agricultural cultivation and includes the steps of sterilization, induced culture of calluses, enrichment culture, bud differentiation culture, seedling strengthening and bud propagation culture and rooting culture. By the aid of the tissue culture technology, when the hoya kerrii is propagated by means of plant tissue culture, the rapid propagation advantage is exerted, and a lot of seedlings can be obtained in a short period; and the plant tissue culture serves as a vegetative propagation method, seedlings are uniform, so that later uniform transplantation and planting management are facilitated, and the consistencies of various characters of grown commercial adult plants and potted plants are also guaranteed. Compared with former propagation methods, according to ingredients of the culture medium and the matched culture methods involved in the method for tissue culture of hoya kerrii, cost can be reduced, the propagation coefficient and the propagation speed can be increased, and the method is applicable to large-scale industrial production.

Owner:云南山里红生物科技有限公司

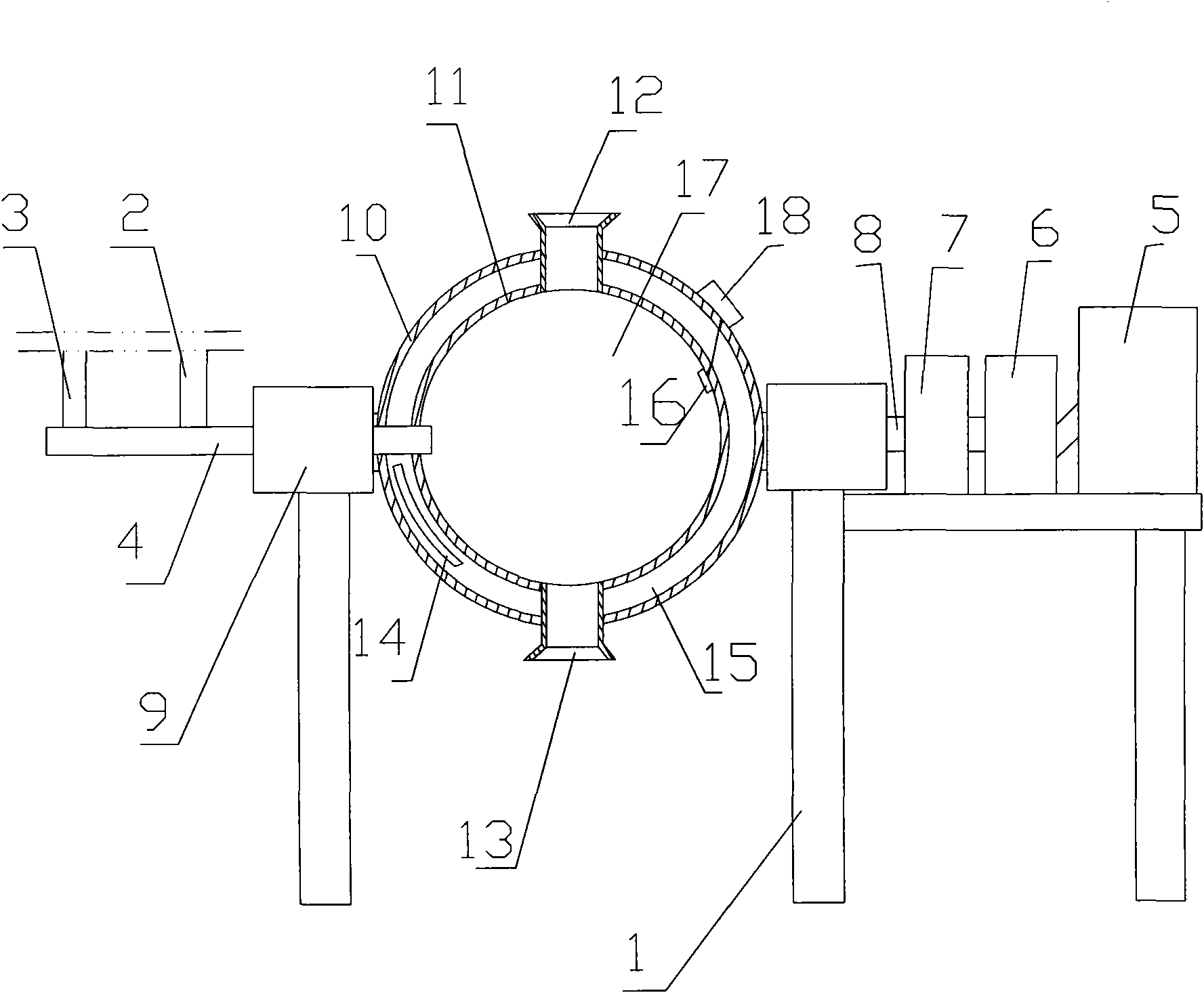

Automatic rotary microbial spore incubator

InactiveCN102212472AStable and uniform qualityReduce labor intensityBioreactor/fermenter combinationsBiological substance pretreatmentsWater storageTemperature control

The invention discloses an automatic rotary microbial spore incubator. The incubator contains a rack, a sterile air adding tube, a steam adding tube, a vent pipe, an incubation box, an electric motor controller, an electric motor, a reduction gearbox and a temperature controller. The automatic rotary microbial spore incubator is characterized in that the incubation box is composed of an outer box body and an inner box body; a water storage cavity is between the outer box body and the inner box body; a heating rod is fixed in the water storage cavity; the inner wall of the incubation cavity is provided with a temperature-sensing probe; the heating rod and the temperature-sensing probe are connected with the temperature controller through wires; rotation shafts on the outer walls of both sides of the outer box body are fixed in two positioning bases of the rack through bearings respectively; the driving shaft of the reduction gearbox is fixedly connected with one rotation shaft on the outer box body; and the end part of the vent pipe passes through the other rotation shaft of the outer box body to enter the incubation cavity. By adopting the automatic rotary microbial spore incubator, spores can be produced automatically; and the produced spores have uniform and stable quality and can be widely used in microbial fermentation production enterprises.

Owner:LAIWU TAIHE BIOCHEM

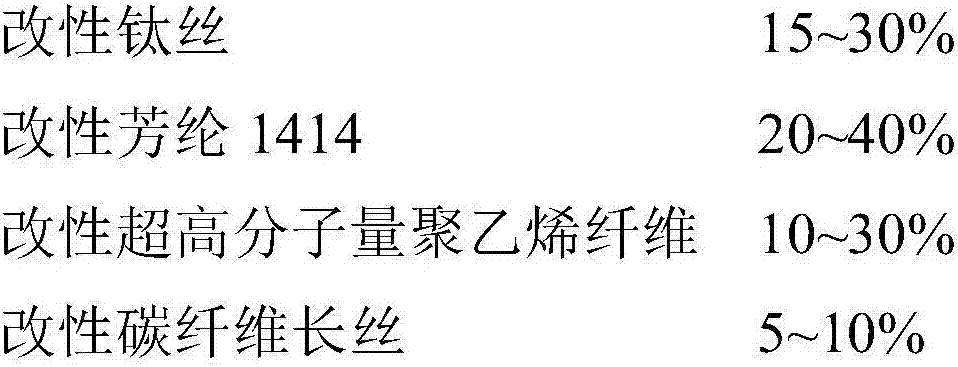

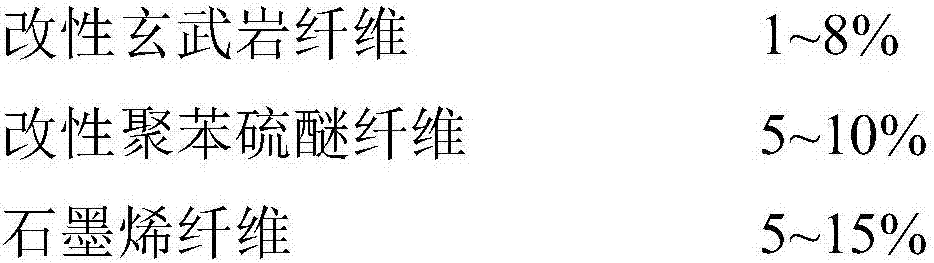

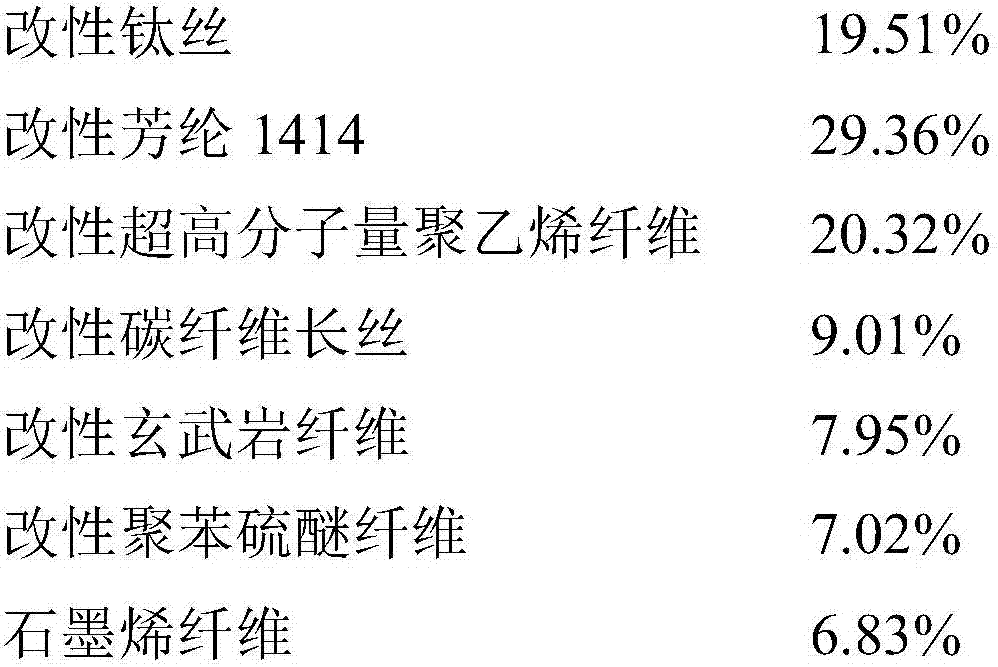

Non-combustible acid-and-alkali-resistant high-temperature-resistant bulletproof fabric and preparation method thereof

ActiveCN107059201AHigh strengthSynergistic bulletproofProtective fabricsHeat resistant fibresYarnPolymer science

The invention relates to a non-combustible acid-and-alkali-resistant high-temperature-resistant bulletproof fabric and a preparation method thereof, and belongs to the technical field of textile materials and protection materials. Five-strand wires M are prepared from covering yarns A, covering yarns B, covering yarns C and covering yarns D according to the number ratio of the yarns of 1:1:1:2, five-strand wires N are prepared from covering yarns A, covering yarns B, covering yarns C and covering yarns E according to the number ratio of the yarns of 1:1:1:2, the five-strand wires M serve as warp, the five-strand wires N serve as weft, the five-strand wires M and the five-strand wires N are woven to form a fabric, and the fabric is treated to prepare the non-combustible acid-and-alkali-resistant high-temperature-resistant bulletproof fabric. The fabric has collaborative bulletproof function of multiple materials and multiple structures by the aid of yarn structures and special fabric structures, and the fabric is high in strength, good in bulletproof effect and excellent in impact resistance.

Owner:广东军铠防护科技有限公司

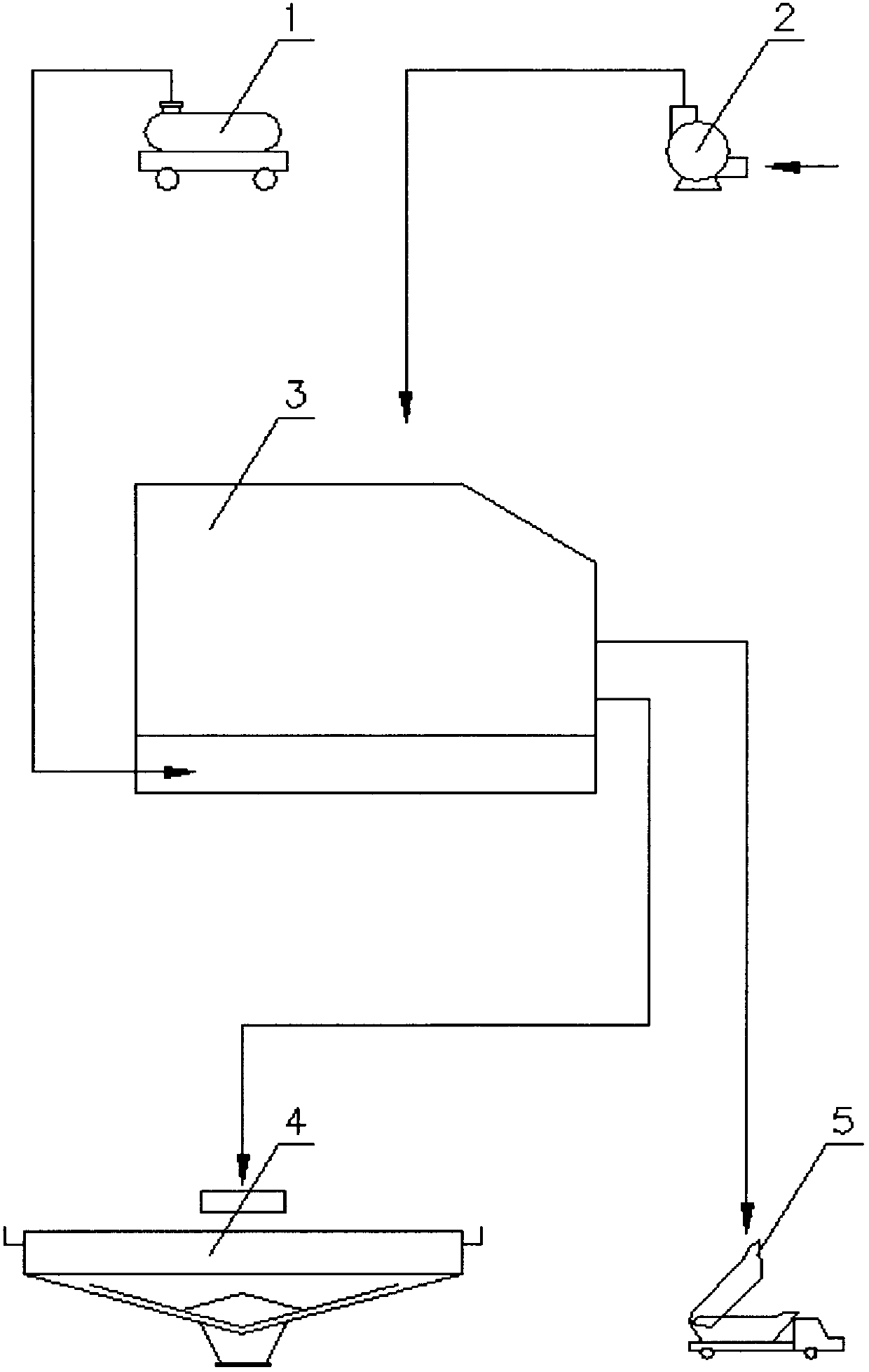

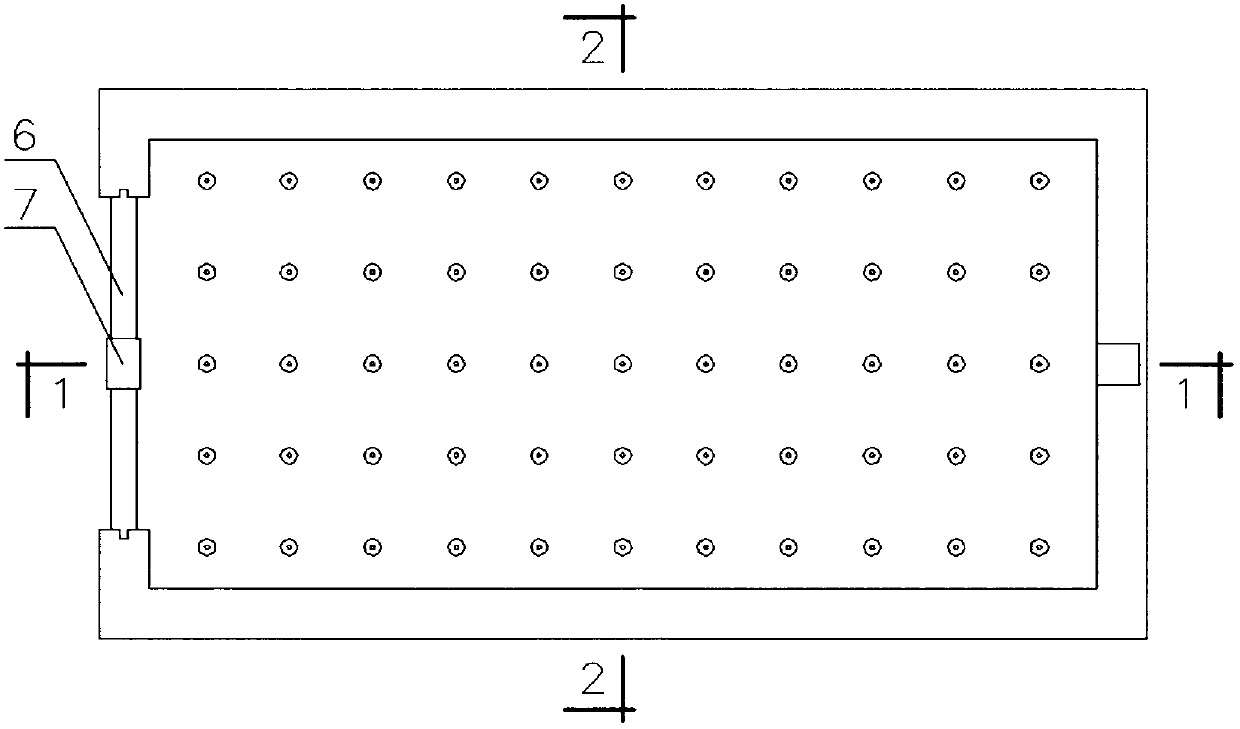

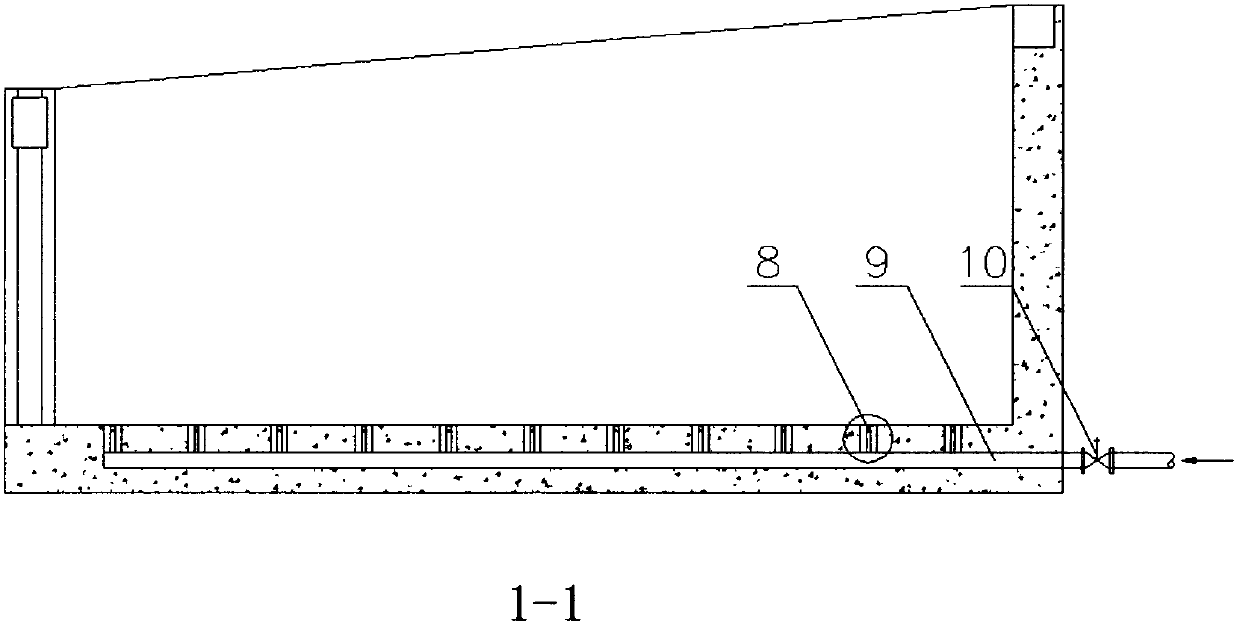

Concentrate dehydrating technology and device

InactiveCN103212223AMoisture content is stableSimple processSedimentation separationPrillFilter media

The invention provides a concentrate dehydrating technology and a device, which is composed of a set of dehydrating pools (3) with special devices (3) and a high pressure air supply system (1) which are manually matched, a dehydration task comprising three processes: settling dehydration, vibration dehydration and pneumatic dehydration, is completed by utilizing self characteristics of concentrate slurry. The concentrate slurry, after natural settling dehydration in the dehydrating pool (3), is blown into a bottom surface of the dehydrating pool (3) by a high pressure blast to generate a big blasting force and a big vibration force, to make solid particles be dehydrated from a hydration membrane package and generate settlement and compaction, and water is extruded out and blown into a water return system (4) by high pressure blast, thereby making a water content of a concentrate product reach a standard requirement. The concentrate product is loaded, transported and sold by a concentrate loading and transporting system (5). The technology and device has advantages of simple flow, small equipment, no intermediate material conveying and transferring link, no filtering medium, energy saving, consumption reduction and low labor intensity, is suitable for dehydration of the concentrate of various metal and nonmetal ores, and is suitable for large scale industrialization production.

Owner:济南友龙建筑安装有限公司

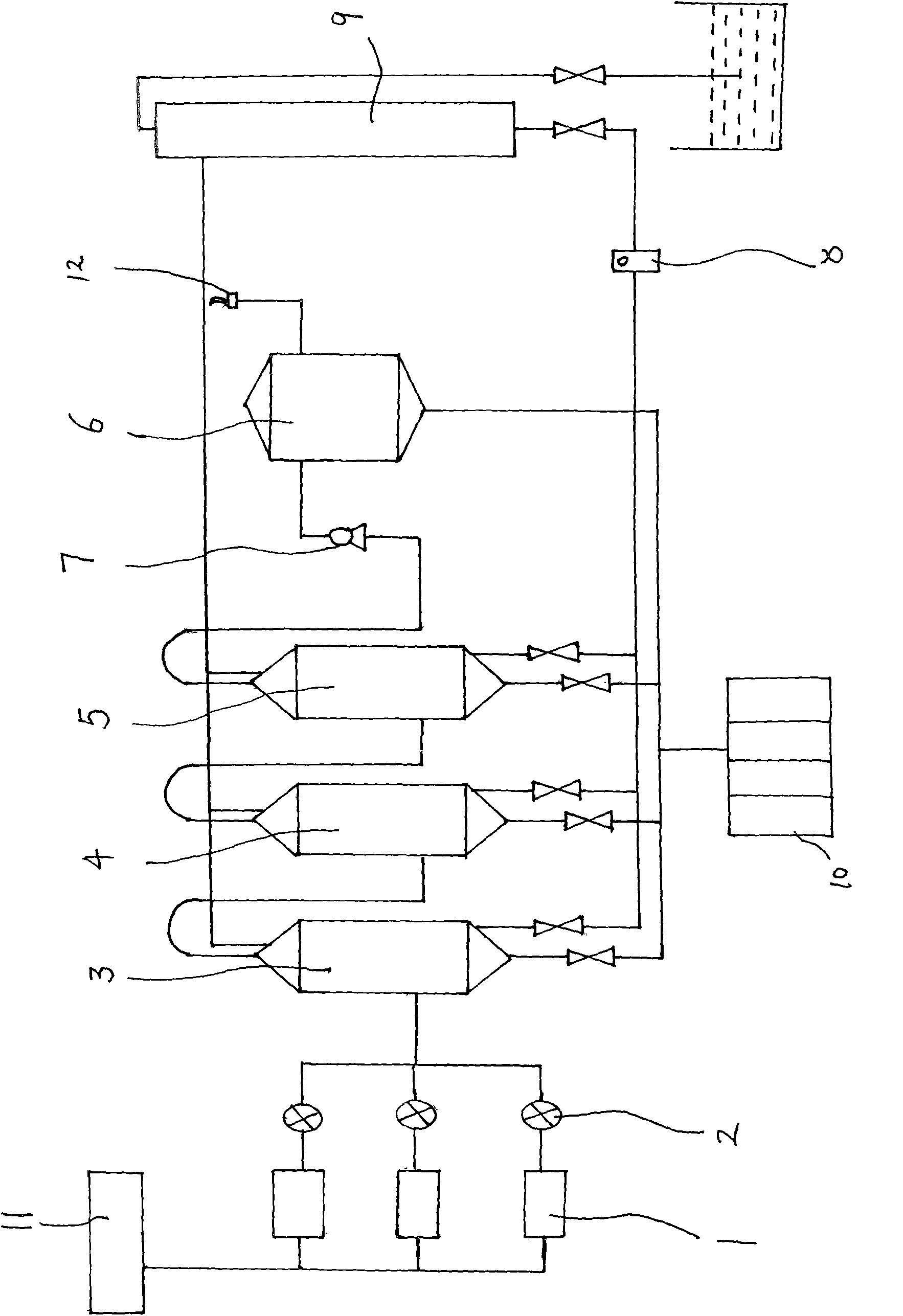

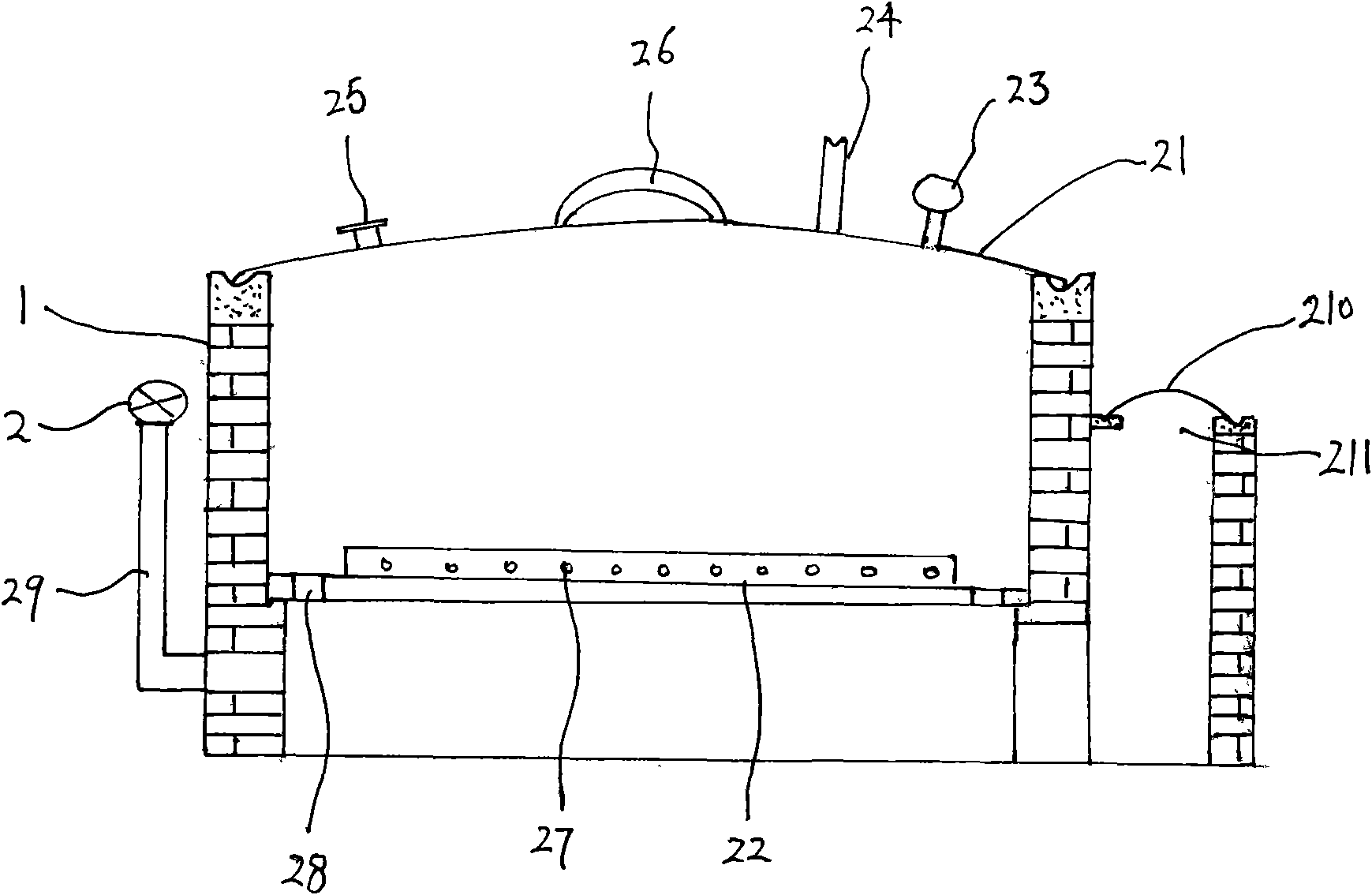

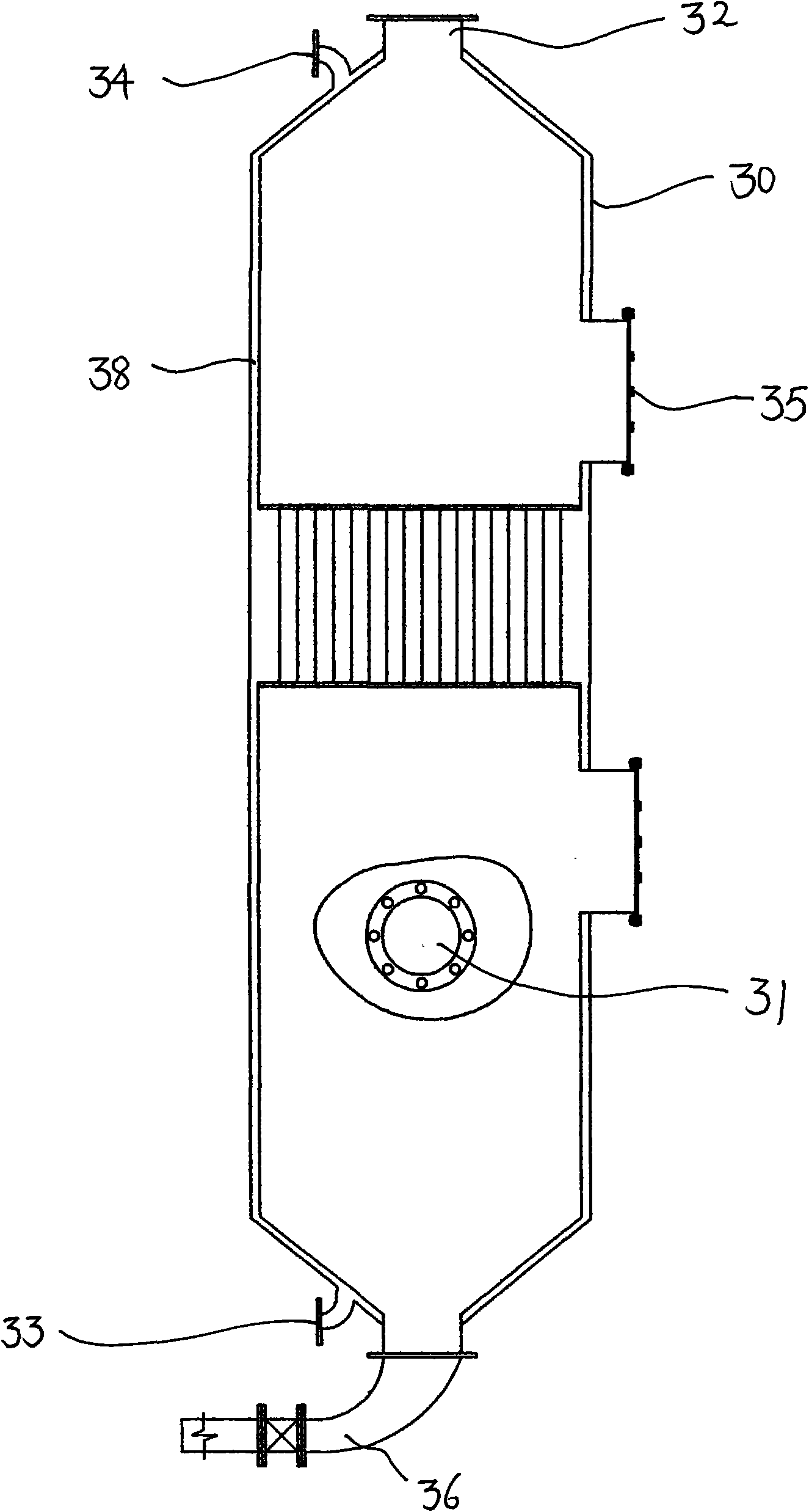

Biomass carbonizing and vaporizing equipment and technology thereof

ActiveCN101570691AThe amount of extraction is easy to controlEasy extractionChemical industryBiofuelsCarbonizationRaw material

The invention belongs to the technical field of biomass comprehensive utilization and discloses biomass carbonizing and vaporizing equipment and a technology thereof. The invention has the following main technical characteristics: the biomass carbonizing and vaporizing equipment comprises a furnace body with a control valve; the furnace body is orderly connected with a condensing tower, a screening tower, a centrifugal tower and a purifying tower, wherein, a frequency conversion fan is arranged between the centrifugal tower and the purifying tower; the condensing tower, the screening tower andthe centrifugal tower are connected with a separation cell and a water cooling tower with a temperature control circulating pump; and the furnace body is also connected with a gas separation unit which is used for rapidly extinguishing fire. The biomass carbonizing and vaporizing equipment and the technology thereof have high mechanization degree; the biomass carbonization and smoke-gas separating, extracting and purifying process are carried out in a fully-closed environment; all raw materials are converted into products; the whole process has no pollution or waste; and the invention realizes energy saving and environmental protection and changes wastes into valuables. The invention has the advantages of safe performance, high carbonizing speed, high extraction quantity and good quality.

Owner:河北序然环保工程有限公司

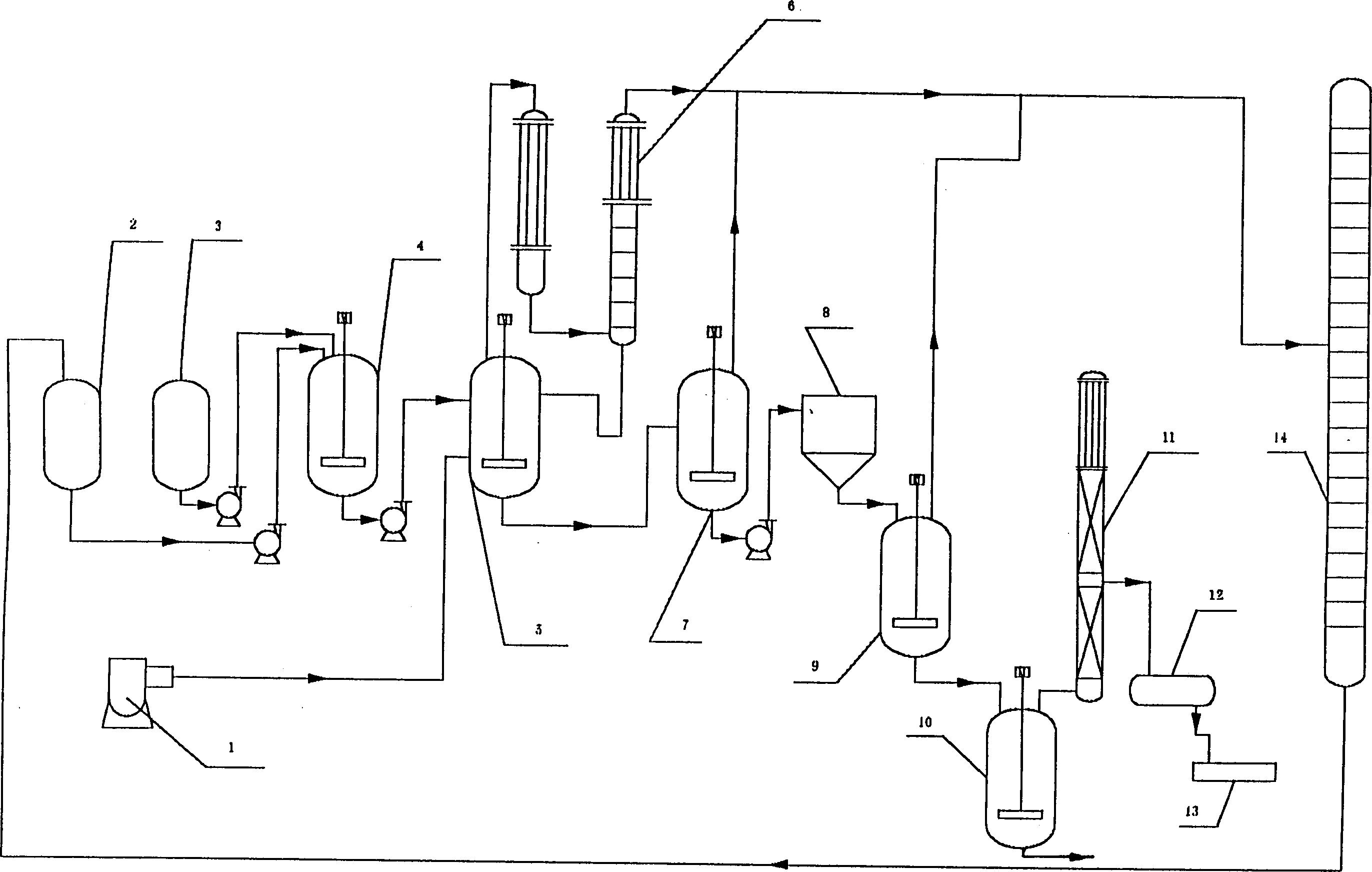

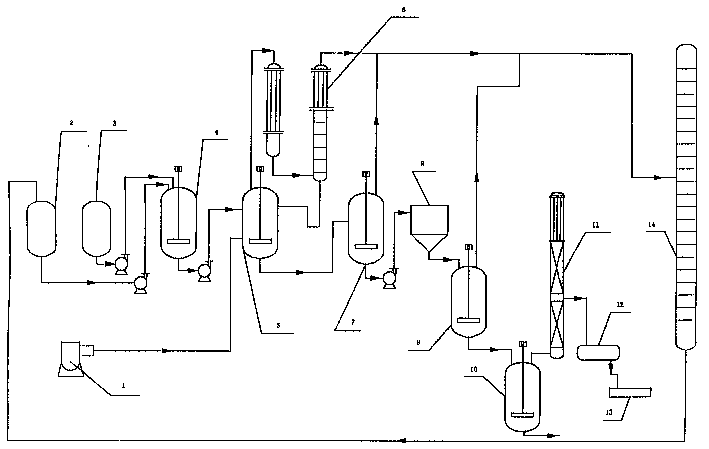

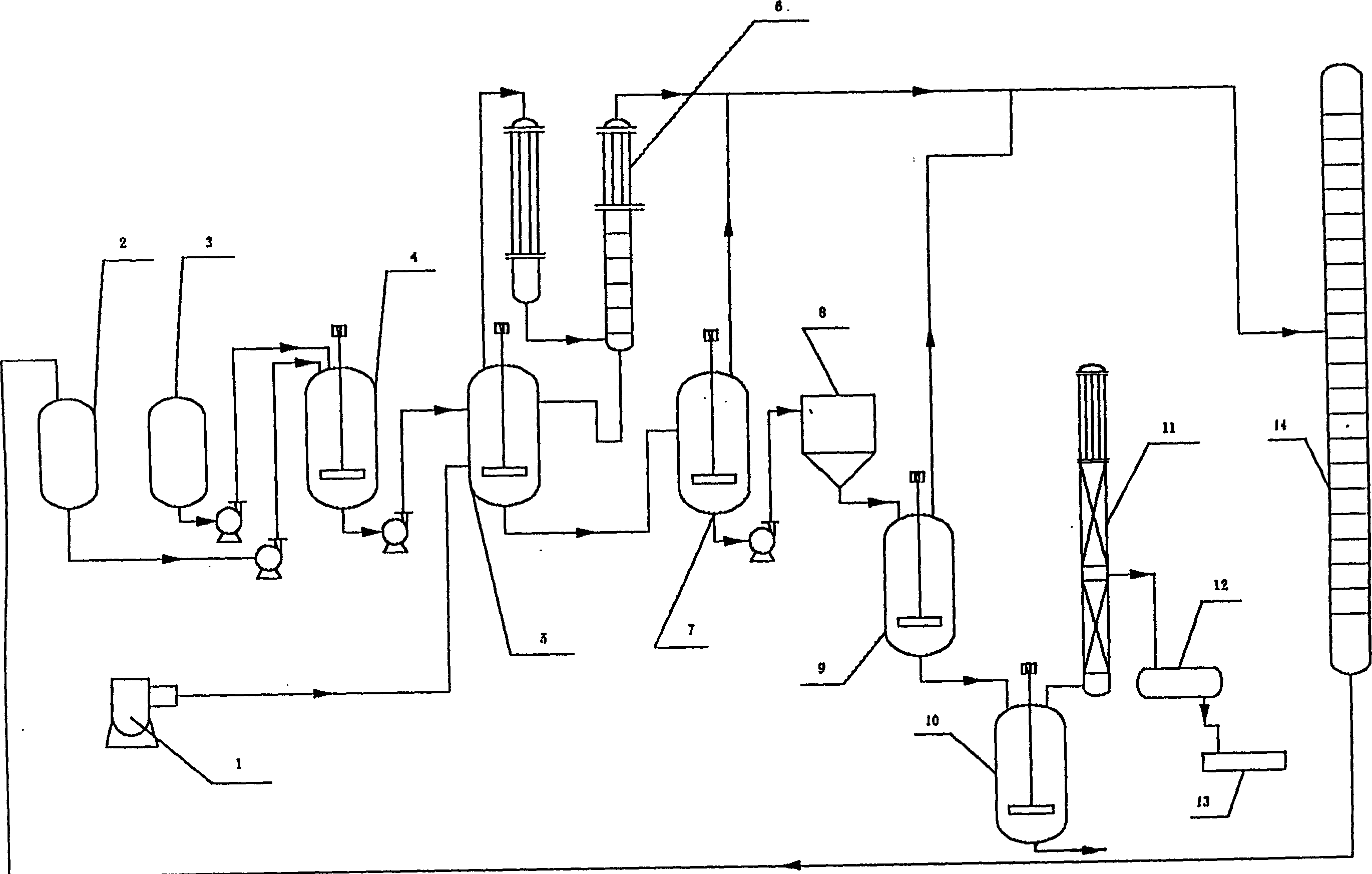

Process for producing trimellitic anhydride by continuous oxidizing process

The invention relates to a method for producing trimellitic anhydride by a continuous oxidation process, which uses trimellitic acid as a raw material, acetic acid as a solvent, and cobalt acetate, manganese acetate, tetrabromoethane or hydrogen bromide as a catalyst. The production process includes the following process: (1) continuous oxidation reaction process of the above mixed material; (2) anhydride forming process; (3) refining process; (4) slicing or granulating process; (5) solvent recovery process. Its advantage is that it adopts continuous oxidation technology and advanced refining technology, so that the yield of the product can reach 120%. Compared with the batch oxidation process, this process has the characteristics of high production safety, complete oxidation reaction, stable product quality, low consumption of raw and auxiliary materials, long service life of equipment, and is suitable for large-scale industrial production. In the production technology, the production scale is small, the product quality fluctuates greatly, the product yield is low, the energy consumption is high, and the service life of the equipment is short. Therefore, the process of the present invention has good promotion value.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

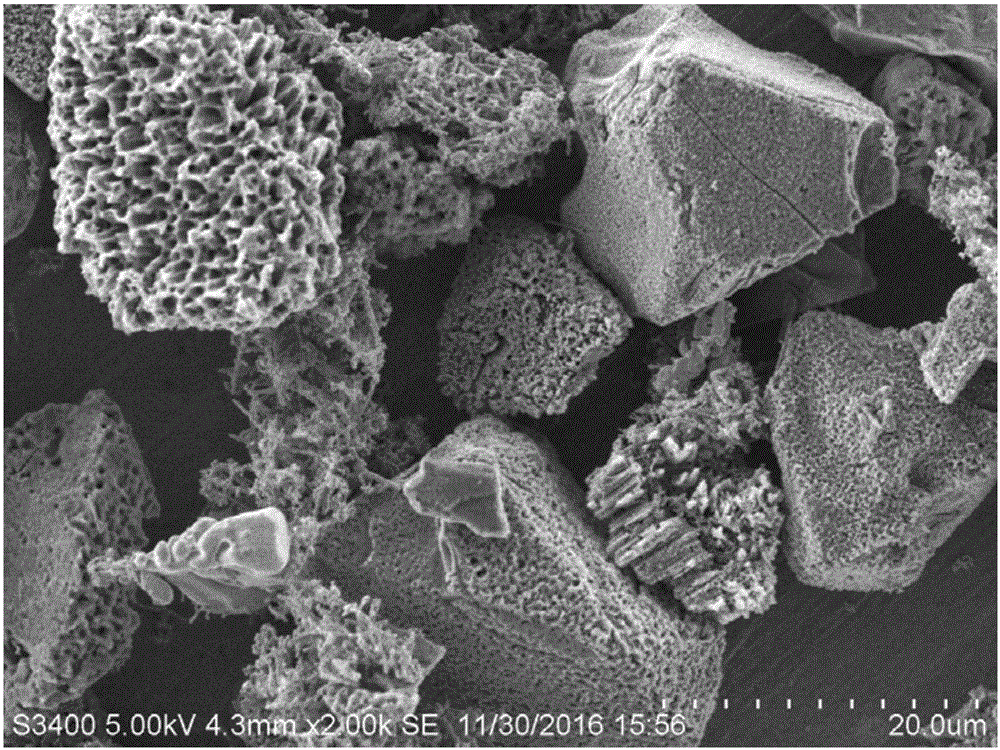

Preparation method of low-cost nano-porous silica powder

InactiveCN106672975AOptimal Control StructureLow costMaterial nanotechnologySilicon compoundsNanoporous siliconRoom temperature

The invention discloses a preparation method of low-cost nano-porous silica powder. The method comprises the following steps of etching of silica powder, namely etching the pretreated silica powder by using an etchant, etching for 1-600 minutes to obtain porous silicon containing nanoscale channels, wherein the apertures are 1-1,000nm and the etchant is a mixed solution prepared from HF, a metal salt, ethanol and water; and treatment of the silica powder, soaking the porous silicon containing nanoscale channels into an acid solution for soaking, and cleaning and removing impurities to obtain the nano-porous silica powder. According to the preparation method, the metal salt is introduced as the etchant, and the shape and form, the aperture, the pore-forming speed and the like of the porous silica powder can be controlled through controlling the concentration of a corrosive solution. Preparation of porous silicon is achieved by using reaction heat release at a room temperature, heating equipment is avoided, meanwhile, the reaction speed is high and the porous silicon can be prepared within a few of minutes in general.

Owner:ZHEJIANG UNIV

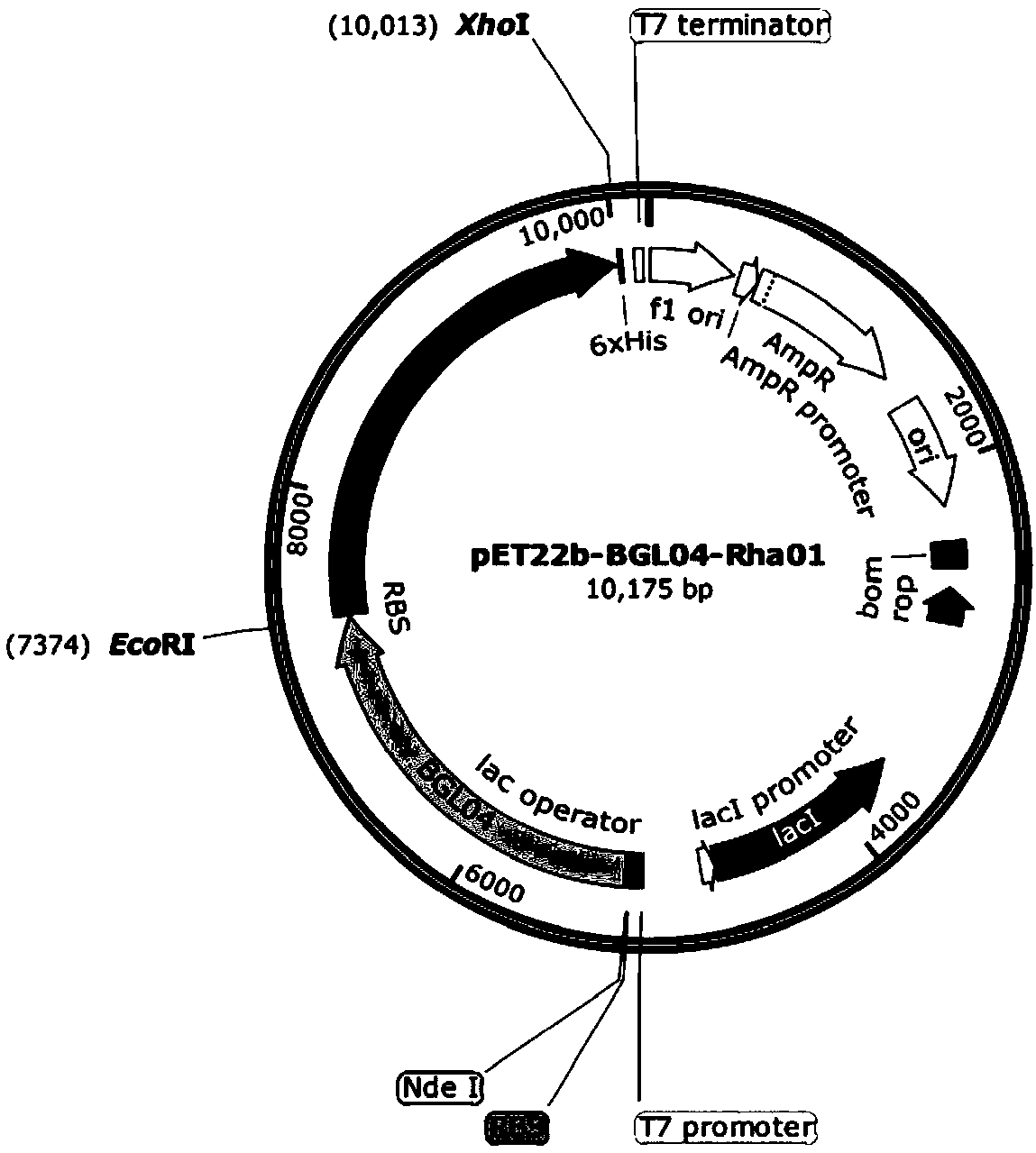

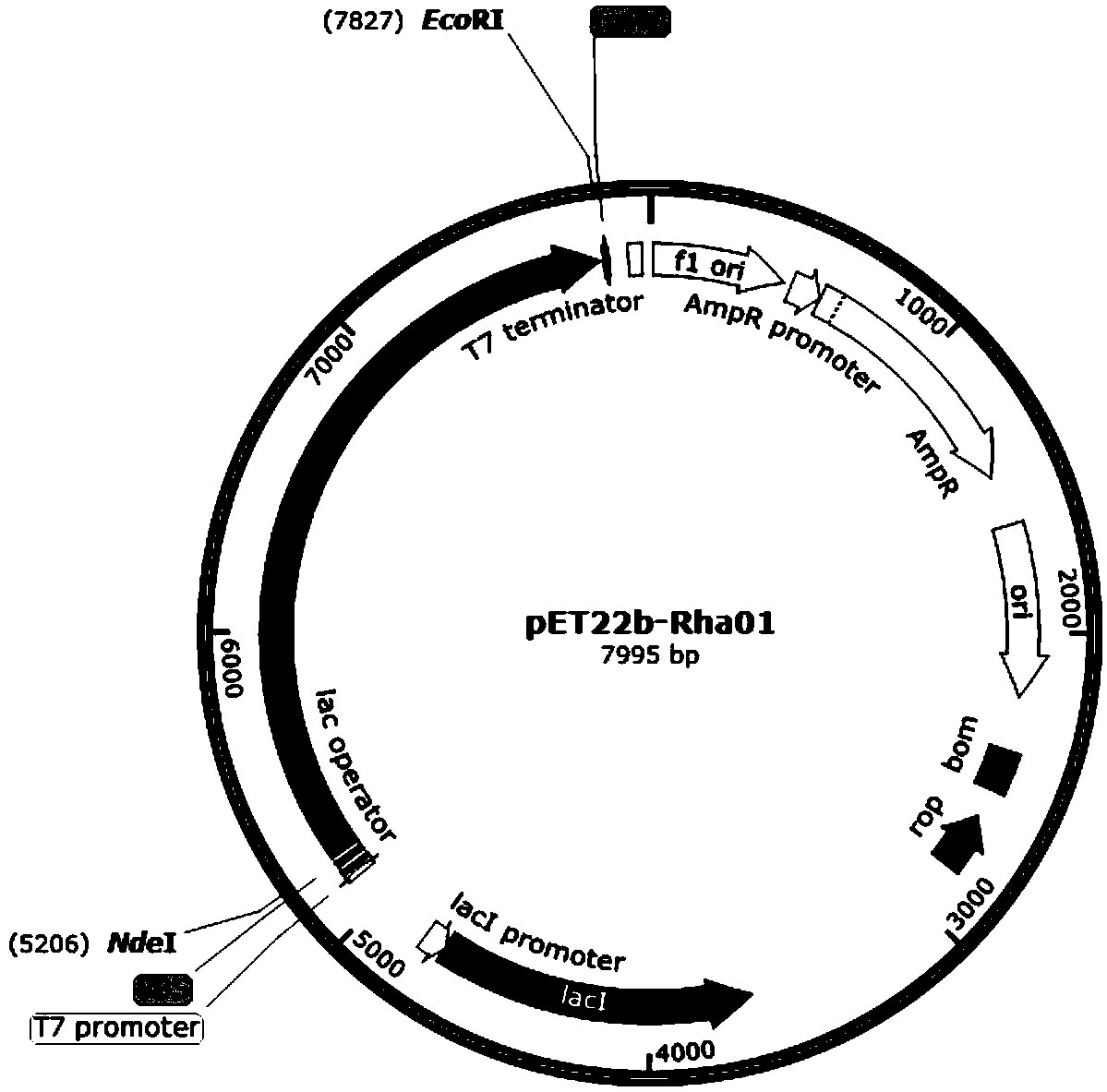

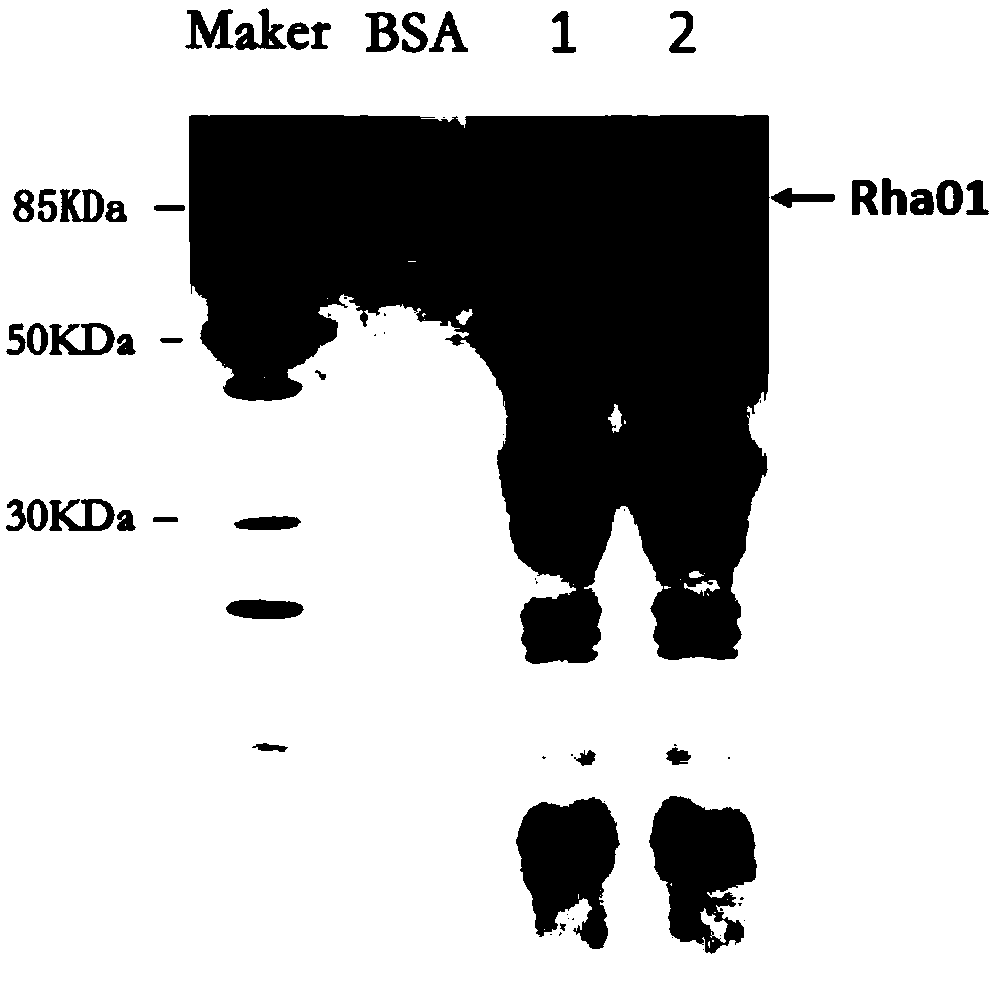

Method for preparing hesperetin, preparation method of hesperetin intermediate and biological enzyme for preparing hesperetin

The present invention provides a method for preparing hesperetin, comprising: suspending hesperidin or neohesperidin in water, and adding a sodium hydroxide solution until the hesperidin or the new hesperidin is completely dissolved, and btaining a substrate preparation solution; adding the substrate preparation solution to a buffer containing alpha-L-rhamnosidase and beta-glucosidase at a rate of0.1 to 1 mL / min for stirring at a flow rate of 0.1 to 1 mL / min to obtain a reaction solution, and after the completion of the addition, continuing the reaction for 0.5 to 1 h, the pH of the reactionsolution is 6.0 to 7.0, and the reaction temperature is maintained at 45 to 65 DEG C. The alpha-L-rhamnosidase is derived from Streptomyces, and the beta-glucosidase is derived from the genus Thermotoxin; adjusting the pH of the reaction solution to 3.0 to 5.0 to completely precipitate the solid product, and collecting the solid product to obtain the hesperetin. The method is efficient, simple, green and environmentally friendly, and can be applied to industrial mass production.

Owner:BONTAC BIO ENG SHENZHEN

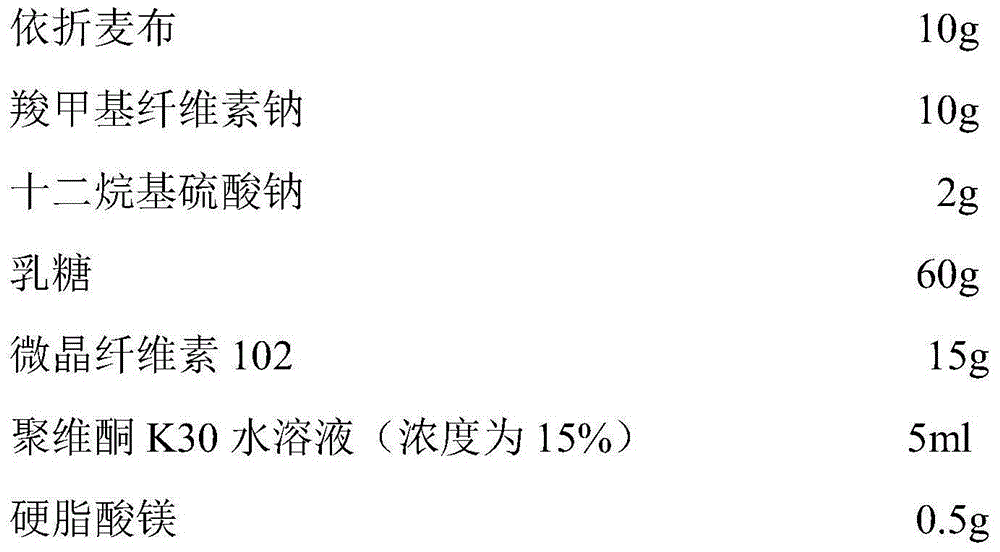

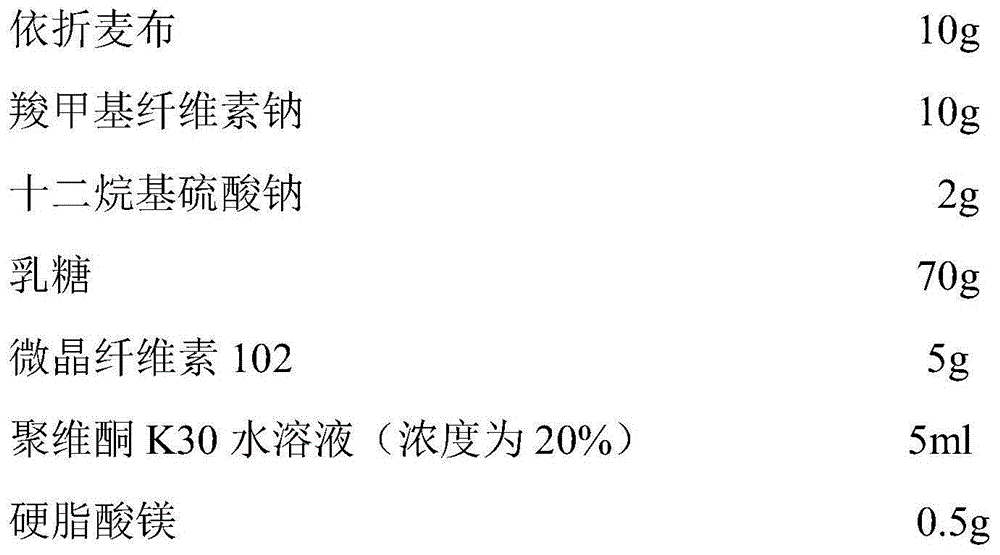

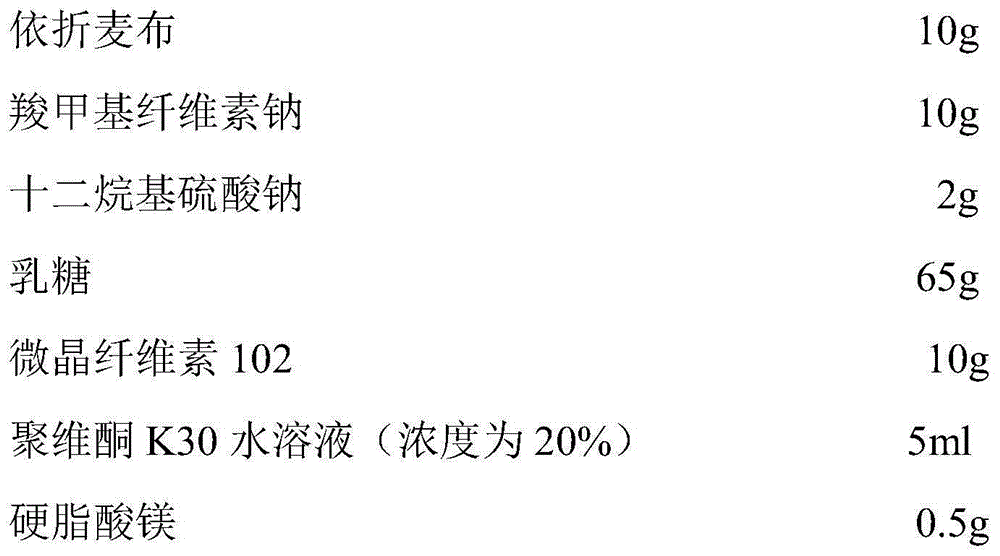

Ezetimibe tablet and preparation method thereof

InactiveCN105213340AReduce fluctuations in dissolutionImprove securityOrganic active ingredientsMetabolism disorderIn vivo absorptionDissolution

The invention provides an ezetimibe tablet and a preparation method thereof. The ezetimibe tablet is prepared from the following components in parts by weight: 10 parts of ezetimibe, 10 parts of a disintegrating agent, 2 parts of a solubilizing agent, 55 to 70 parts of a filling agent, 5 to 15 parts of microcrystalline cellulose, 5 parts of an adhesive and 0.5 parts of a lubricant. According to the ezetimibe tablet disclosed by the invention, the fluctuation of the dissolution of the ezetimibe tablet can be effectively reduced, the dissolution difference is reduced, the safety of the ezetimibe tablet in a medicine using process is improved, and the fluctuation of in-vivo absorption of the ezetimibe tablet is reduced; meanwhile, according to the preparation method of the ezetimibe tablet, a production process is simplified, and the method can adapt to large-scale industrial production.

Owner:WUXI FORTUNE PHARMA

Sodium Diacetate production method

InactiveCN1765867AChange volatilityReduce volatilityCarboxylic acid salt preparationAcetic acidState of art

The invention relates to method to produce sodium diacetate by acetic acid and soda, which comprises: with one-step synthesis method, adding soda slowly into stirring acetic acid and additive in reaction process; with normal-pressure inverse flow reaction mean, obtaining the objective product. In this method, the reaction material can contact sufficiently to form even solution system, changes slabby state of materials, reduces reaction temperature below 110Deg to decrease acetic acid volatilization and energy consumption, increases yield to more than 95%, and fit to industrial production in large scale.

Owner:中盐湖南株洲化工集团有限公司

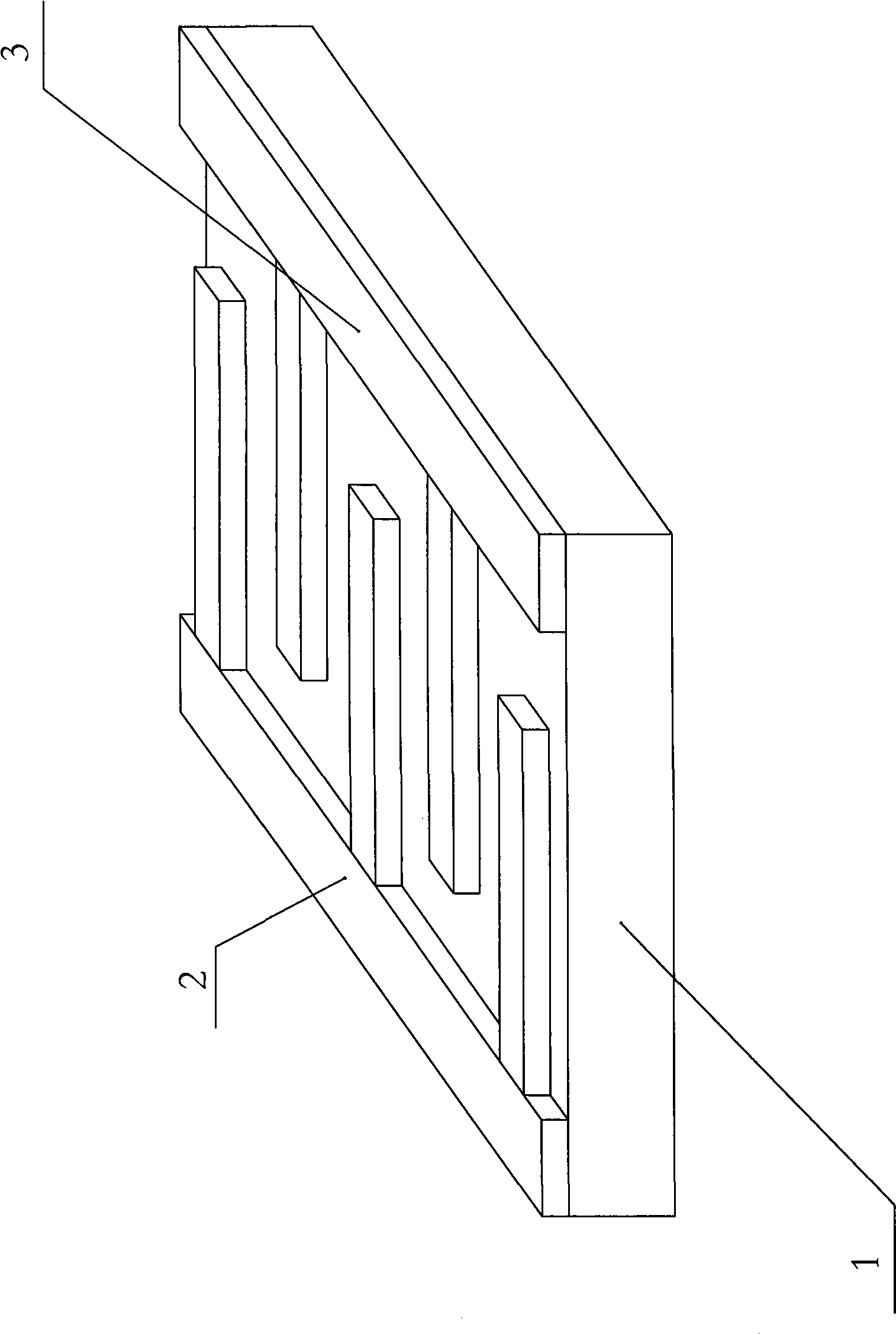

Back contact type solar cell and manufacturing process thereof

InactiveCN101478009ALow costAdapt to large-scale industrial productionFinal product manufacturePhotovoltaic energy generationScreen printingEngineering

The invention discloses a back-contact solar battery and the fabrication method thereof. The back-contact solar battery comprises electrodes fabricated by silk screen printing technology, an n-type crystal Si substrate with a square resistance of 50 to 300 omega / square and a thickness of 100 to 300 mum, an anti-reflection layer and a passivation layer arranged on the front surface of the Si substrate, and interdigitated metal electrode pairs printed on the back surface, wherein the electrode pairs include Al / Ni electrode and Sb / Ni electrode; the Al / Ni electrode contains Al 0.1 to 10 wt% with a purity larger than 99.99% and particle size less than 10 mum; and the Sb / Ni electrode contains Sb 0.1 to 10 wt% with a purity larger than 99.99% and particle size less than 10 mum. The back-contact solar battery suits industrial production, and has lower cost and high photoelectric conversion efficiency.

Owner:JINGRI SOLAR SCI & TECH

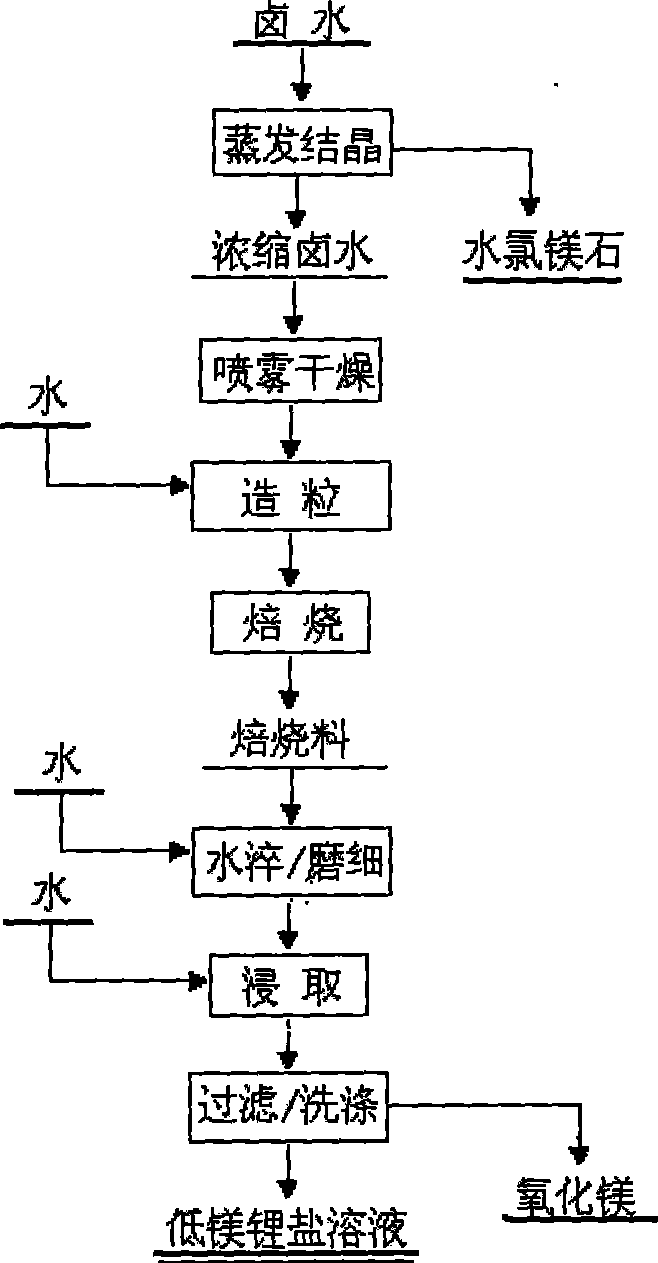

Method for pre-de-magnesium enriched lithium from salt lake bittern with high-magnesium-lithium ratio with dry method de-magnesium

ActiveCN101508449ARealize pre-demagnesium enrichment of lithiumReduce lossesMagnesium chloridesAlkali metal chloridesHigh magnesiumLithium chloride

The invention relates to a method for removing magnesium-enriched lithium in advance from saline lake brine with a high magnesium-lithium ratio through dry-process magnesium removal. The method is to take the saline lake brine with the high magnesium-lithium ratio as a raw material and adopt the technological steps of brine concentration, spray drying, granulation, roasting, water leaching, and the like to remove most magnesium in the brine, so that lithium can be conveniently extracted with low cost. The main technical points of the method comprises that: the dry-process magnesium removal is based on a high-temperature hydrolysis principle of magnesium chloride to convert most soluble magnesium compounds into magnesium compounds (MgO) which are difficult to be dissolved in water, and magnesium oxychloride (MgOHCl) which is hydrolyzed in the water, so that soluble lithium chloride and magnesium chloride (which are mainly generated by hydrolysis under the condition of the water leaching of the magnesium oxychloride) are dissolved out through the water leaching, and the removal of the magnesium-enriched lithium in the brine in advance is realized. The method comprehensively utilizes magnesium resources and lithium resources of saline lakes, has the characteristics of high magnesium removal efficiency, good enriching effect of lithium salts, high recovery rate, low energy consumption, low cost, small project investment, and the like, and is particularly suitable for industrial production on a large scale. In addition, the whole process is simple, clean and environment-friendly.

Owner:CENT SOUTH UNIV

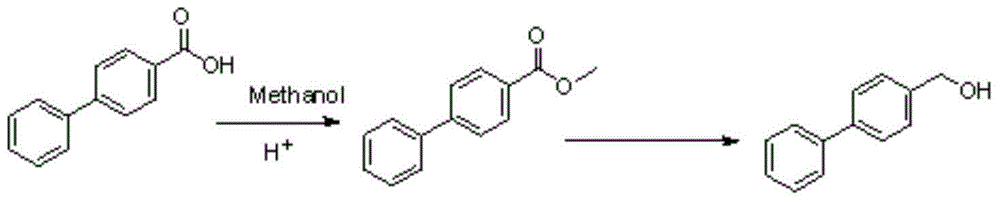

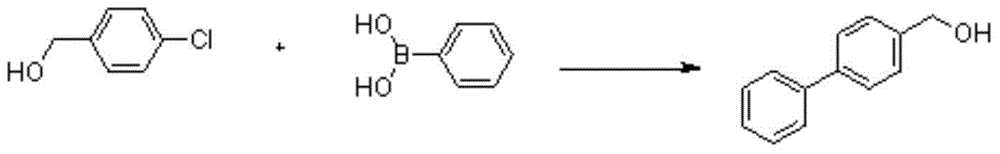

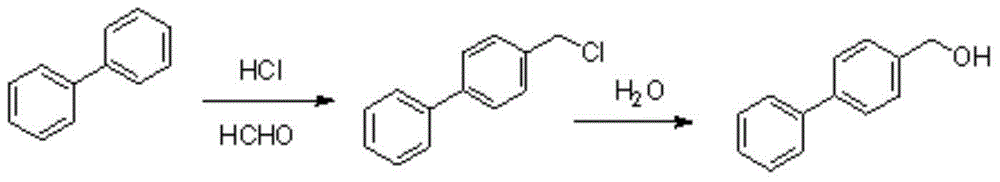

4-biphenyl methanol synthetic method

ActiveCN105198707AHigh yieldReduce contentOrganic compound preparationHydroxy compound preparationRefluxOrganic solvent

The invention discloses a 4-biphenyl methanol synthetic method. The method comprises the steps that 1, biphenyl, paraformaldehyde, phosphoric acid, concentrated hydrochloric acid and a catalyst are mixed and heated to 100-120 DEG C, and are subjected to a reaction in a closed system for 2-48 h, cooled and layered into a water layer and an organic layer; 2, the water layer obtained in the step 1 is removed, water is added into the organic layer, heating reflux is performed for 8-48 h, cooling and filtering are performed, and a crude product is obtained; 3, an organic solvent is used for achieving recrystallization on the crude product obtained in the step 2, and 4-biphenyl methanol is obtained. The 4-biphenyl methanol synthetic method has the advantages of being capable of obtaining raw materials easily, low in cost, suitable for industrial production and the like.

Owner:浦拉司科技(上海)有限责任公司

Method for preparing magnetization based surfactant and application

The invention discloses a method for preparing a magnetization based surfactant and application. The method comprises the following steps of: (1) isomer combination, namely uniformly combining more than three or less than six of triethanolamine, sodium sulfate, ethylene diamine tetraacetic acid, sulfite yeast distiller wort, calcium dodecy and sodium oxalate; and (2) magnetization, namely magnetizing the isomer by using a permanent magnetic field to obtain the magnetization based surfactant. The method is simple and has convenient operation. The surfactant is used for producing conventional portland cement, portland slag cement, portland fly ash cement, portland-pozzolan cement and composite portland cement to effectively consume industrial waste residue, volcanic ash and other mixed materials, reduce environmental pollution, effectively solve the problems that doping of the mixed materials causes early-strength reduction, hardening slowdown, label reduction and the like of the cement, greatly improve yield and performance of the cement, reduce consumption of energy and resources, and provide powerful technical guarantee for low-carbon cement production.

Owner:HUBEI UNIV OF TECH +1

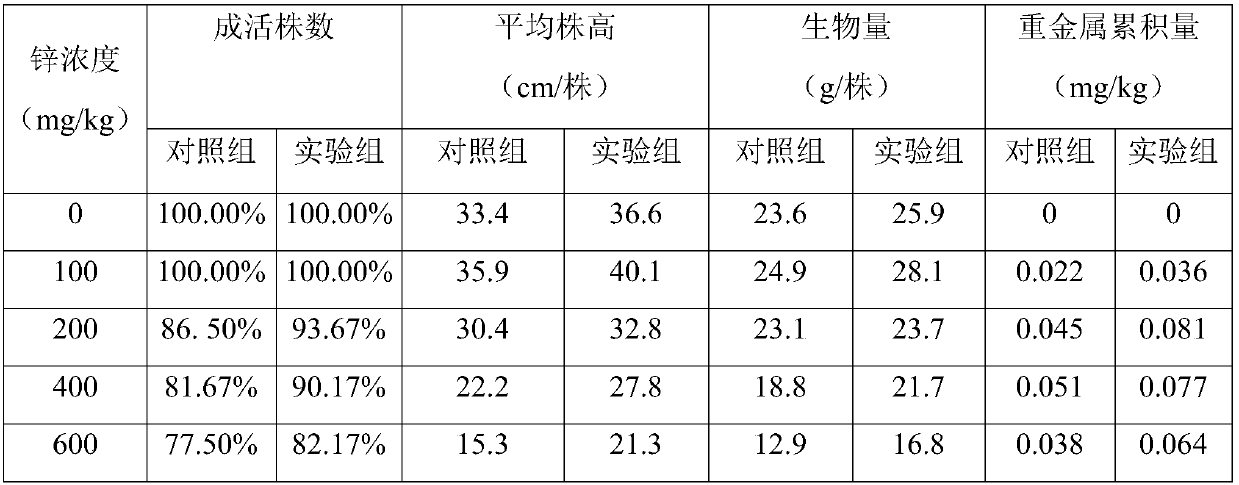

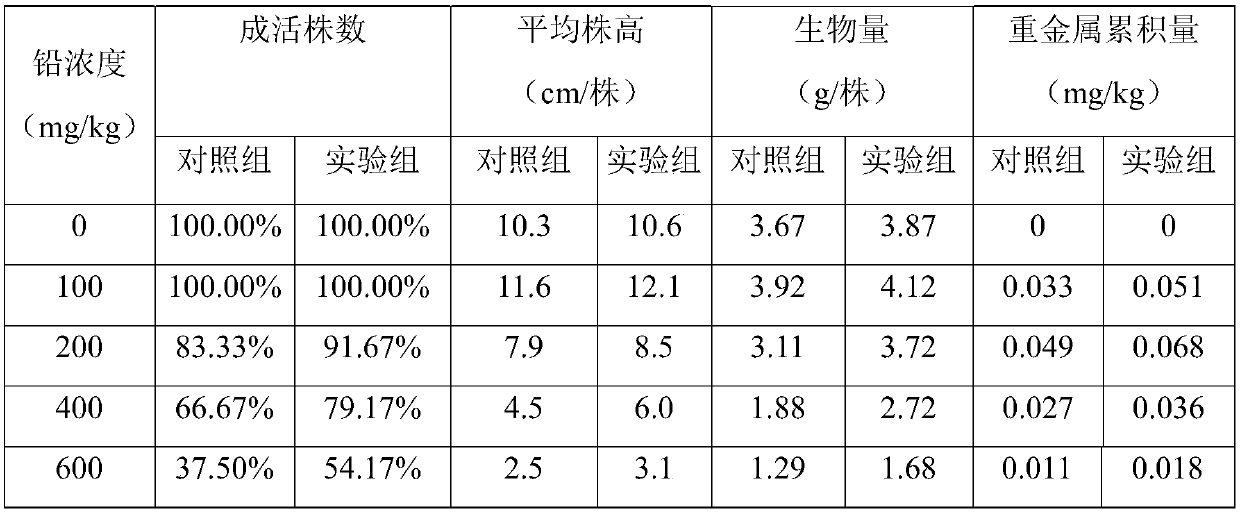

Composite functional microbial preparation, and preparation method and application thereof

InactiveCN109516869APromote growthImprove the growing environmentSuperphosphatesFungiMicrobial agentSoil heavy metals

The invention discloses a composite functional microbial preparation, and a preparation method and application thereof. The composite functional microbial preparation is prepared from the following components in parts by mass: 85-93 parts of attachment matrixes, 2-8 parts of basic nutrient solutions and 1-3 parts of composite microbial agents, wherein the composite microbial agents contain entomogenous verticillium agents, aspergillus oryzae agents, bacillus mucilaginosus agents and bacillus subtilis agents. The preparation method includes the steps of mixing the basic nutrient solutions withthe attachment matrixes, aging, and adding the composite microbial agents for fermentation to obtain the preparation. The preparation can effectively alleviate the toxicity of heavy metals in the plant rhizosphere soil, and can improve the soil structure and the plant root environment, enhance soil nutrition and promote plant growth; the preparation has the advantages of simple process, low production cost and the like, and can adapt to large-scale industrial production; the preparation provided by the invention can be used for promoting energy plant restoration of heavy-metal contaminated soil, thereby having good application value and application prospect.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Finishing method of high-isolation performance non-woven fabric and high-isolation non-woven material thereof

ActiveCN102995400BLittle impact on air permeabilityReduce consumptionFibre treatmentAlcoholEngineering

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

Method for extracting active substance from guava leaves

InactiveCN109010438AGood directionStrong penetrating powerSolid solvent extractionPlant ingredientsUltra high pressureCavitation

The invention discloses a method for extracting an active substance from guava leaves. The method comprises the following steps: (1) pulverizing the guava leaves and sieving the material, and then using an ethanol solution containing ionic liquid as a solvent for ultrahigh pressure extraction; 2) performing ultrasonic extraction on an obtained extract, performing centrifugation on the obtained extract, and taking a supernatant for standby; and (3) stirring the supernatant while adding ethanol, performing standing and centrifugal filtering and performing freeze-drying on the precipitate to obtain the active substance. The extraction method of the invention combines the ultrasonic wave and a high pressure technology without interference, and realizes the coordinated treatment of the ultrasonic wave and a high pressure reaction, the mechanical effect, warming effect, physical and chemical effect (including dispersion effect, thixotropic effect, and cavitation effect) of ultrasonic waves,as well as excellent directionality, strong penetrating ability, and high efficiency and low energy consumption of ultra-high pressure extraction are used, the extraction rate can be effectively increased, energy consumption can be reduced, the extraction time can be saved, and the method is suitable for large-scale industrial production.

Owner:THE SECOND XIANGYA HOSPITAL OF CENT SOUTH UNIV +1

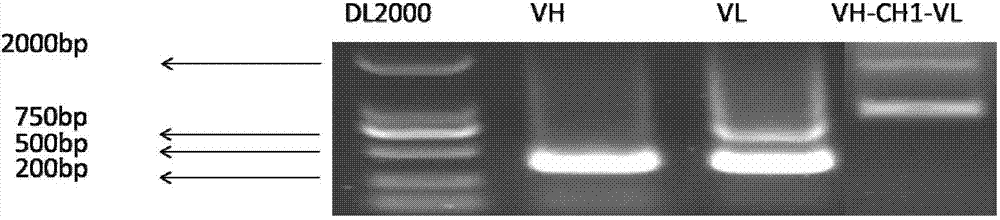

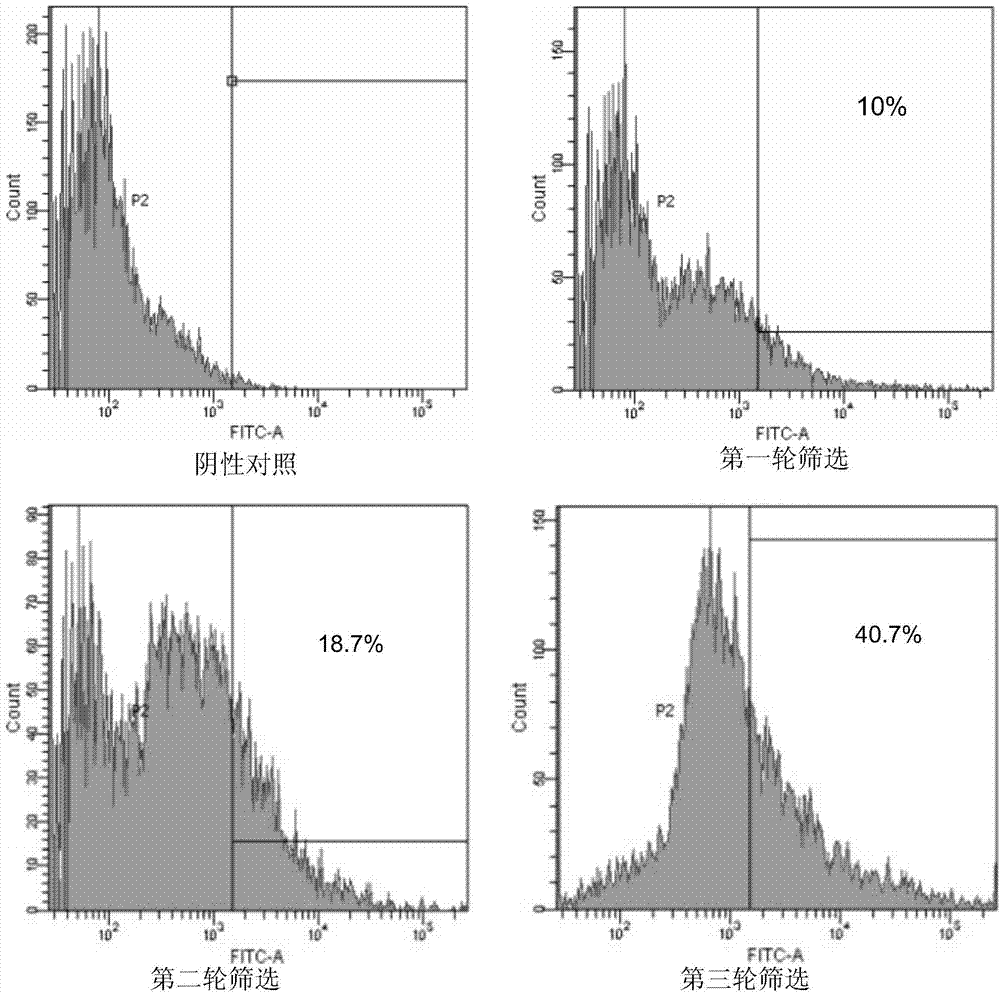

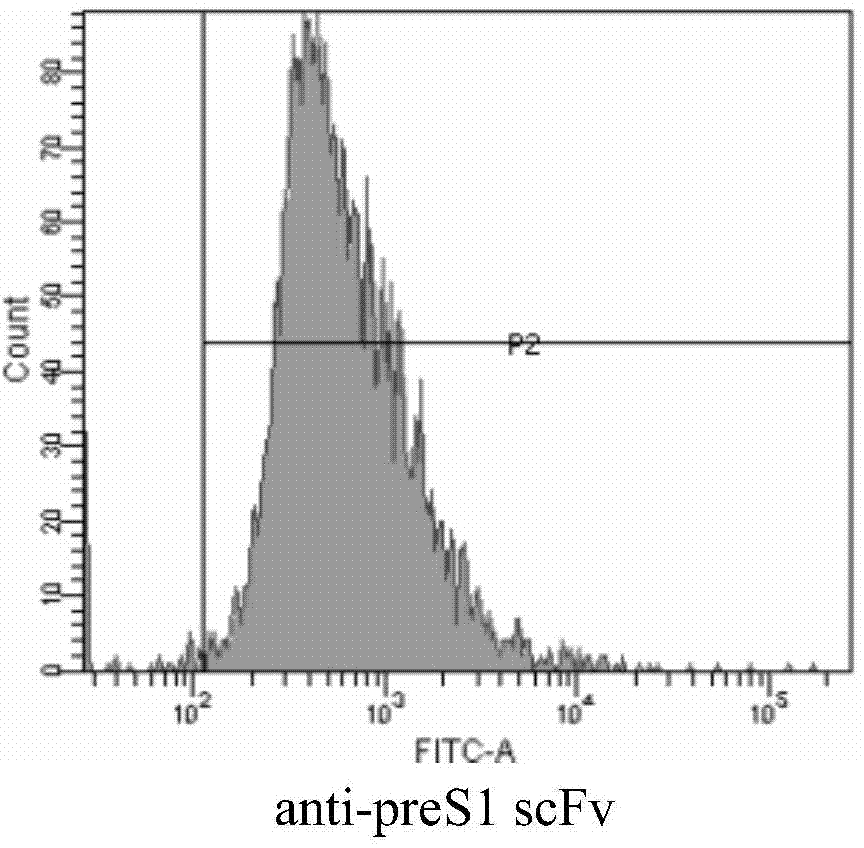

ScFv antibody, encoding gene thereof and application of scFv antibody to preparation of preparation for treating or preventing hepatitis B

ActiveCN104761639AAvoid infectionAvoid the risk of spreading diseaseBacteriaImmunoglobulins against virusesDiseaseSingle-Chain Antibodies

The invention discloses an scFv antibody, an encoding gene thereof and application of the scFv antibody to preparation of a preparation for treating or preventing hepatitis B. The single-chain antibody is composed of a heavy-chain variable region, a light-chain variable region and a joining region between the heavy-chain variable region and the light-chain variable region, wherein the amino acid sequence of the heavy-chain variable region ranges from the first position to the 127th position counted from the N tail end of a sequence 1 in a sequence table; and the amino acid sequence of the light-chain variable region ranges from the 143rd position to the 255th position counted from the N tail end of a sequence 1 in the sequence table. Compared with a blood product, the single-chain antibody disclosed by the invention has the following advantages that no immune serum is needed, and the problem that the immune serum is limited because of few sources is solved; the risk that diseases are spread through blood because the blood product contains HBIG is avoided; the scFv antibody belongs to a human-derived protein so as not to generate immunological rejection reaction of an organism when being directly applied to a human body; and the scFv antibody is suitable for large-scale industrial production, the yield can be increased, and the cost can be reduced.

Owner:JIANGSU KANIONREAL BIOMEDICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com