Concentrate dehydrating technology and device

A concentrate and process technology, which is applied in the field of concentrate dewatering process and device, can solve the problem of inability to effectively remove the water wrapped in the hydration membrane of fine-grained concentrate, and achieves favorable height difference configuration, low production cost, and metal loss. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

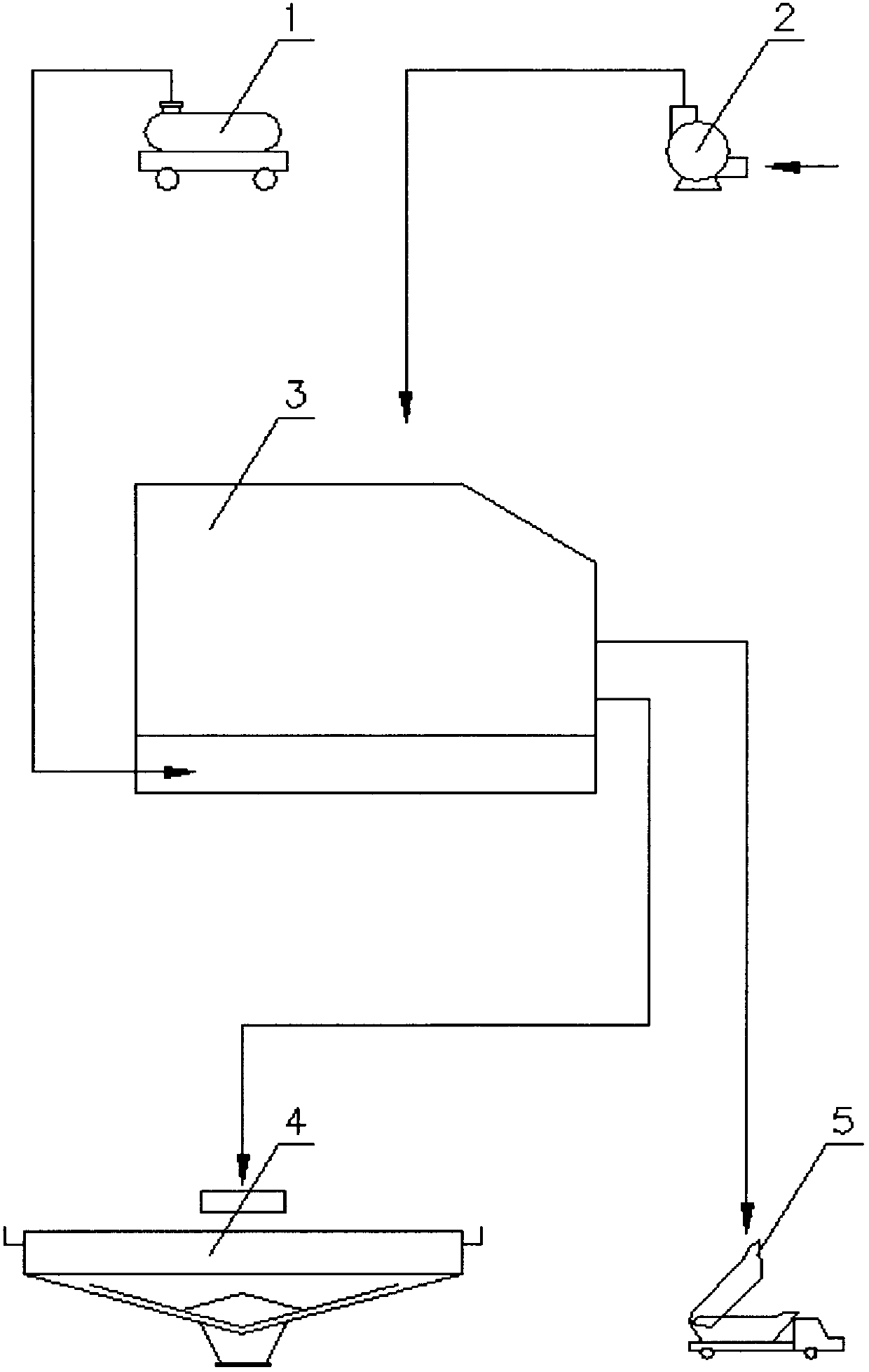

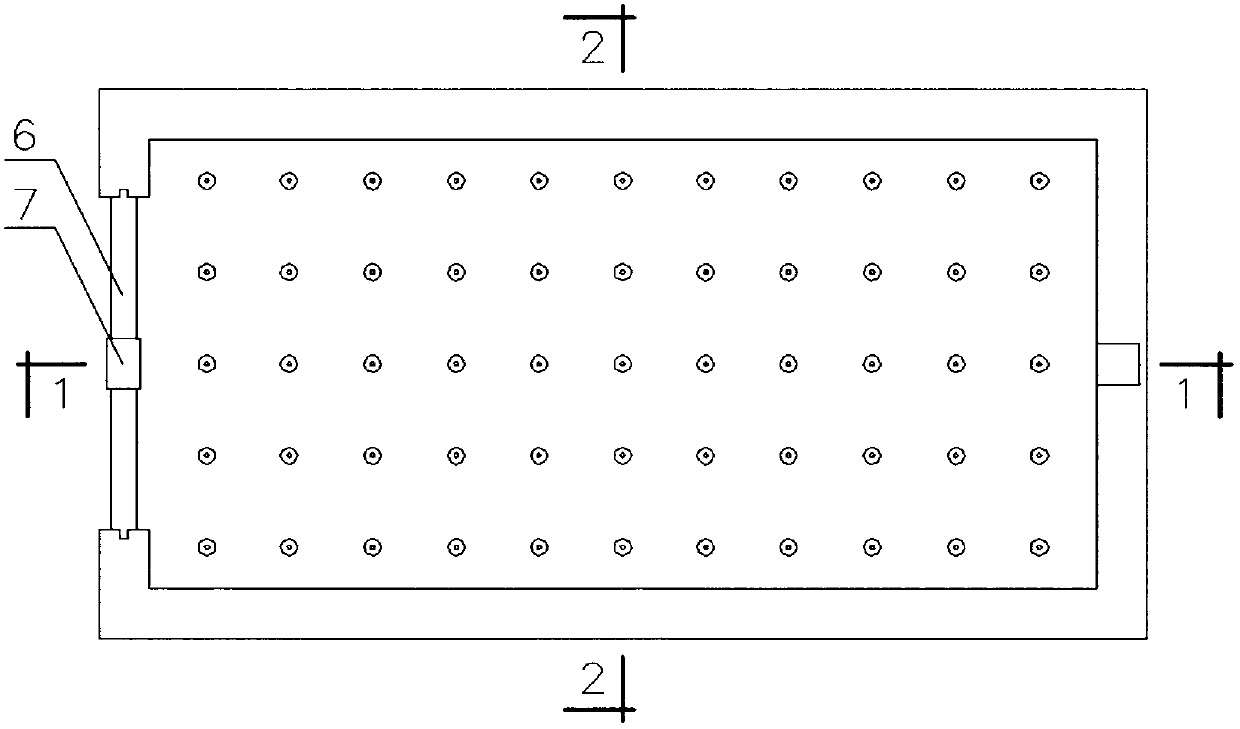

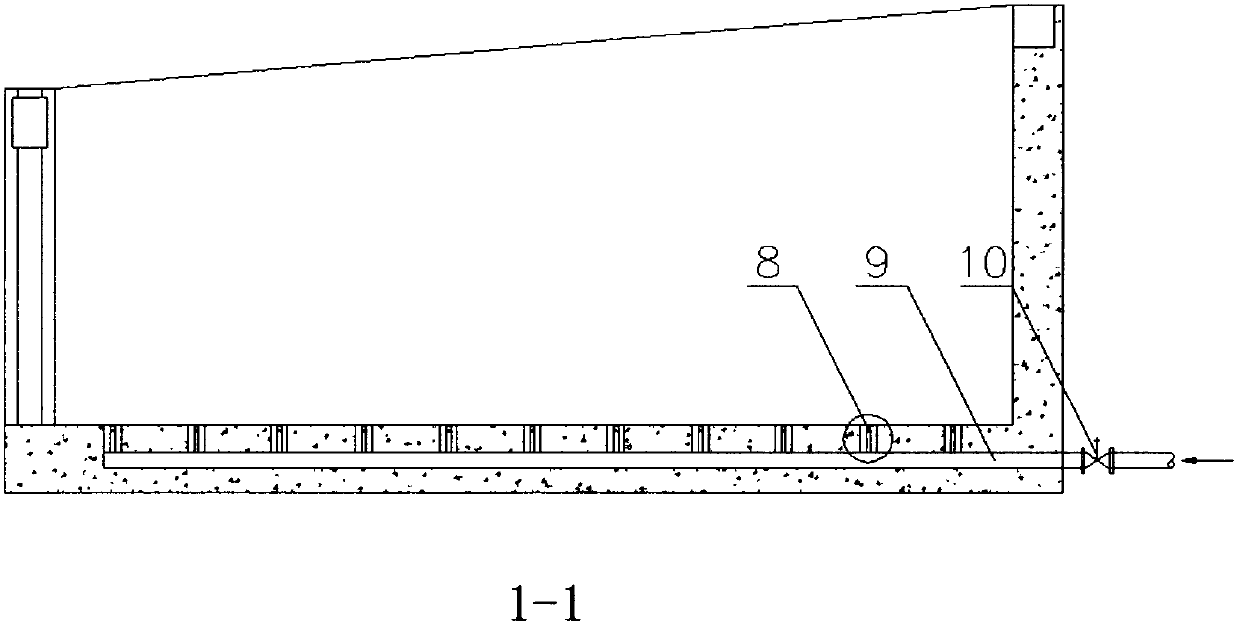

[0020] In the accompanying drawing, the concentrate produced in the process of mineral processing (ore dressing) enters the dehydration tank [3] by the concentrate slurry supply system [2] by pumping or gravity flow, and the solid minerals in the concentrate slurry are Its own physical characteristics sink into the bottom of the pool to form a concentrate deposit layer in the way of free settlement and interference settlement, and the liquid becomes supernatant water and is discharged from the adjustable overflow port [7] into the return water system [4] for recycling; The concentrate slurry continuously enters the dewatering tank [3], and the overflow port [7] needs to be adjusted randomly. When the overflow port [7] is adjusted to the upper limit and the overflow is mixed with fine-grained solid minerals that have not completely settled, the The conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com