Sludge dewatering method and system based on microwave electrolytic catalytic oxidation

An electrolytic catalytic oxidation and sludge dehydration technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of reducing the activation energy of the solution, weakening chemical bonds, etc., and achieve high strength and activation The effect of reducing and increasing the oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

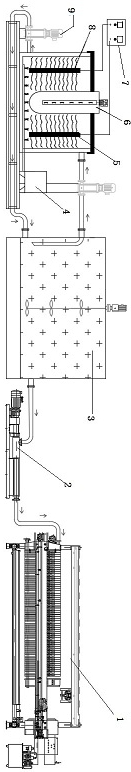

Image

Examples

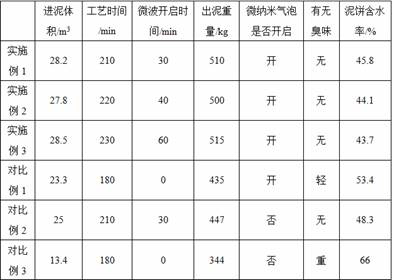

Embodiment 1

[0038] A method for dewatering sludge based on microwave electrolytic catalytic oxidation, comprising the following steps:

[0039] Step 1. Mud feeding into the mud storage tank: a mud feeding device is installed on the mud storage tank, and the water content of the mud feeding is controlled at 96%;

[0040] Step 2. Microwave catalytic oxidation pretreatment: Turn on the circulation pump, DC power supply, micro-nano bubbles, and microwave. The DC power supply voltage is 36V, the microwave frequency is 0.915Ghz, and the microwave power is 9kw. The generated hydroxyl radicals and the sludge in the sludge The organic matter is fully oxidized in the electrolytic cell. The anode material in the electrolytic cell is a carbon-carbon composite material, in which the base material is a mesophase pitch-based carbon fiber, the reinforcing phase is a highly conductive pitch impregnating agent, and the cathode material is made of stainless steel. The pump cycle The time is 30 minutes;

[...

Embodiment 2

[0045] A method for dewatering sludge based on microwave electrolytic catalytic oxidation, comprising the following steps:

[0046] Step 1. Mud feeding into the mud storage tank: a mud feeding device is installed on the mud storage tank, and the water content of the mud feeding is controlled at 99%;

[0047] Step 2. Microwave catalytic oxidation pretreatment: Turn on the circulation pump, DC power supply, micro-nano bubbles, and microwave. The DC power supply voltage is 24V, the microwave frequency is 2.45Ghz, and the microwave power is 30kw. The generated hydroxyl radicals and the sludge in the sludge The organic matter is fully oxidized in the electrolytic cell. The anode material in the electrolytic cell is a carbon-carbon composite material, in which the base material is a mesophase pitch-based carbon fiber, the reinforcing phase is a highly conductive pitch impregnating agent, and the cathode material is made of stainless steel. The pump cycle The time is 40 minutes;

[...

Embodiment 3

[0052] A method for dewatering sludge based on microwave electrolytic catalytic oxidation, comprising the following steps:

[0053] Step 1. Mud feeding into the mud storage tank: a mud feeding device is installed on the mud storage tank, and the water content of the mud feeding is controlled at 98%;

[0054] Step 2. Microwave catalytic oxidation pretreatment: Turn on the circulating pump, DC power supply, micro-nano bubbles, and microwave. The DC power supply voltage is 30V, the microwave frequency is 2.45Ghz, and the microwave power is 25kw. The generated hydroxyl radicals and the sludge in the sludge The organic matter is fully oxidized in the electrolytic cell. The anode material in the electrolytic cell is a carbon-carbon composite material, in which the base material is a mesophase pitch-based carbon fiber, the reinforcing phase is a highly conductive pitch impregnating agent, and the cathode material is made of stainless steel. The pump cycle The time is 60min;

[0055]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com