Solvent-free heating-free method for synthesizing potassium diformate

A potassium diformate, heating-free technology, applied in carboxylate preparation, organic chemistry, etc., can solve the problems of control of unfavorable reaction intensity, increase of production cost, increase of energy consumption, etc., and achieve economic feasibility and production efficiency Improve and reduce the effect of raw material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: 11.0 mL of 88.0% formic acid was added to a 50 mL three-necked round-bottomed flask, and at room temperature and under magnetic stirring, 7.78 g of solid flake potassium hydroxide (82%) was slowly added. With the addition of potassium hydroxide, the temperature gradually increased. When the temperature reaches 80°C, slow down the feeding rate, and keep the temperature at 80±1°C by controlling the feeding rate. After the addition, the stirring reaction was continued at room temperature, and the stirring was stopped when the temperature dropped to 45°C. The reaction product was cooled and crystallized at room temperature, and dried in a 60°C electric constant temperature drying oven. After drying, the product was ground to obtain 14.6 g of potassium diformate, with a product yield of 98.7%.

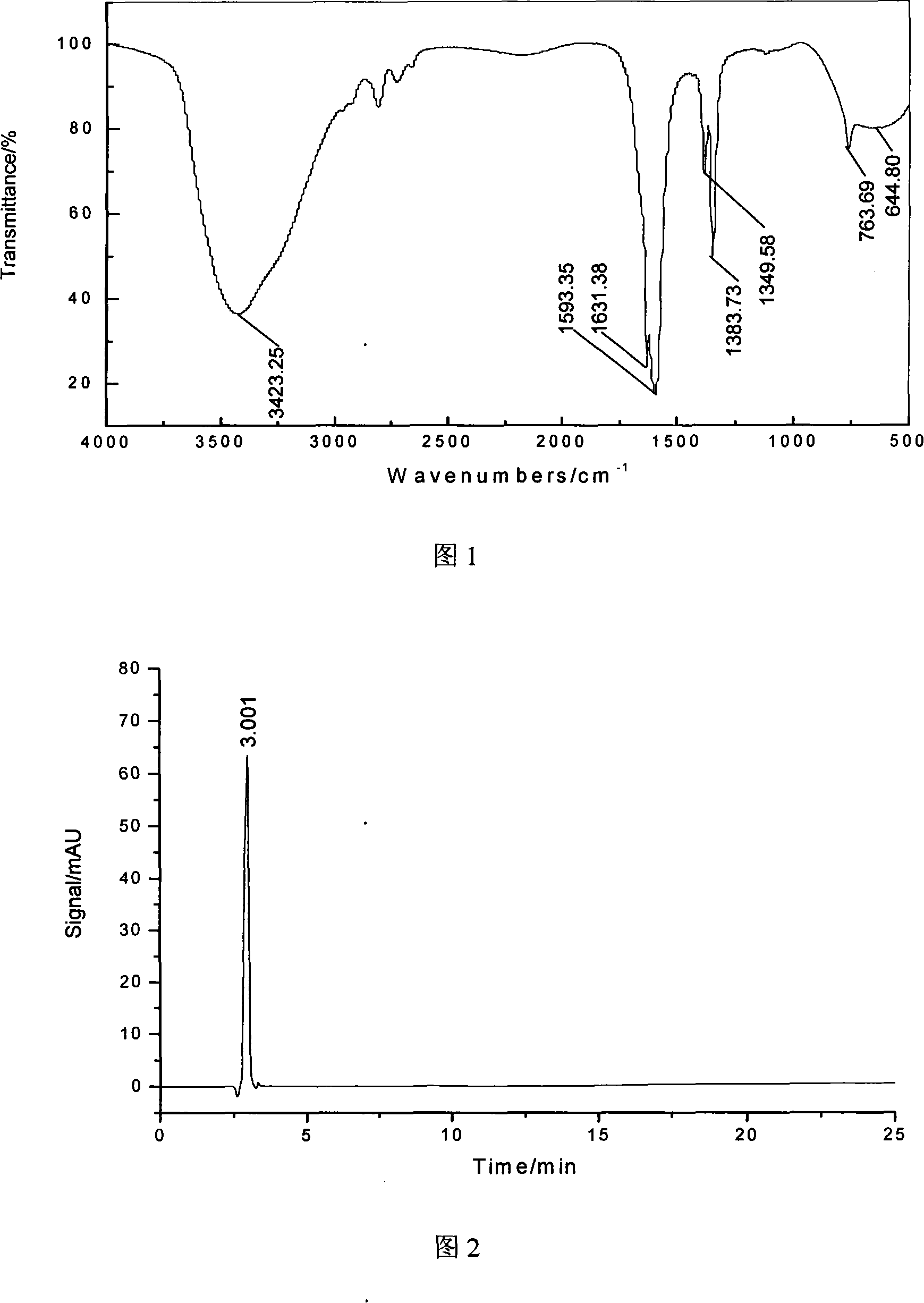

[0017] The infrared spectrogram of gained potassium diformate product is shown in Figure 1, and among the figure absorption peak and the corresponding peak of potassium d...

Embodiment 2

[0018] Embodiment 2: adopt the raw material ratio in the embodiment 1, when the temperature reaches 70 ℃ during the feeding process, slow down the feeding speed, keep the temperature at 70 ± 1 ℃ by controlling the feeding speed. After the addition, the stirring reaction was continued at room temperature, and the stirring was stopped when the temperature dropped to 20°C. The rest of the conditions and steps are the same as in Example 1, finally obtaining 14.1 g of potassium diformate, and the product yield is 95.3%.

Embodiment 3

[0019] Embodiment 3: adopt the raw material ratio in the embodiment 1, when the temperature reaches 70 ℃ during the feeding process, slow down the feeding speed, keep the temperature at 70 ± 1 ℃ by controlling the feeding speed. After the addition, the stirring reaction was continued at room temperature, and the stirring was stopped when the temperature dropped to 50°C. All the other conditions and steps are the same as in Example 1, finally obtaining 14.5 g of potassium diformate, and the product yield is 98.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com