Ezetimibe tablet and preparation method thereof

A technology of ezetimibe and microcrystalline cellulose, applied in the field of ezetimibe tablets and their preparation, can solve the problems of unsustainable and stable release of drug effect, damage to human organs and tissues, large fluctuation of absorption in the body, and the like, Achieve the effect of adapting to large-scale industrial production, simplifying the production process and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

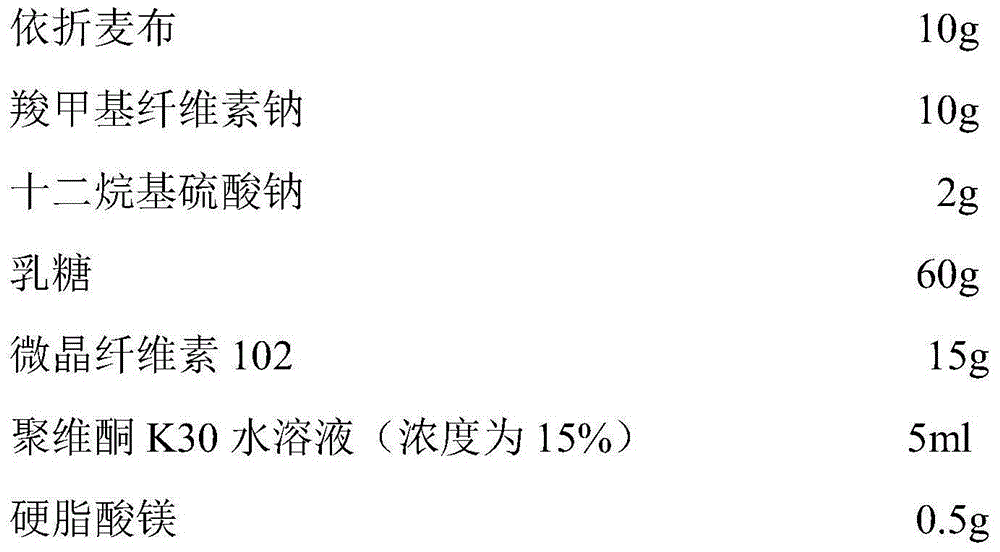

[0030] Prescription quantity: 1000 tablets

[0031]

[0032] Among them, the particle diameter D of microcrystalline cellulose 102 15 48±2.4μm, D 85 65±1.5μm, porosity (5.0±0.4)×10 -5 cm 3 / g.

[0033] Pass lactose, sodium carboxymethyl cellulose and sodium lauryl sulfate through a 80-mesh sieve (sodium lauryl sulfate should be crushed if necessary), and microcrystalline cellulose 102 and magnesium stearate through a 60-mesh sieve respectively Add the sodium lauryl sulfate, sodium carboxymethyl cellulose and ezetimibe of the prescribed amount into the mixer successively, mix for 5 minutes to mix evenly to obtain a mixed powder, and pass the mixed powder through a 40-mesh sieve; then Add lactose in equal increments; transfer the mixed powder to the wet granulator, set the stirring and chopping speed, and mix for 10 minutes; set the stirring and chopping speed, start the wet mixing granulator, and start spraying the poly Vitone K30 aqueous solution, the spray time is con...

Embodiment 2

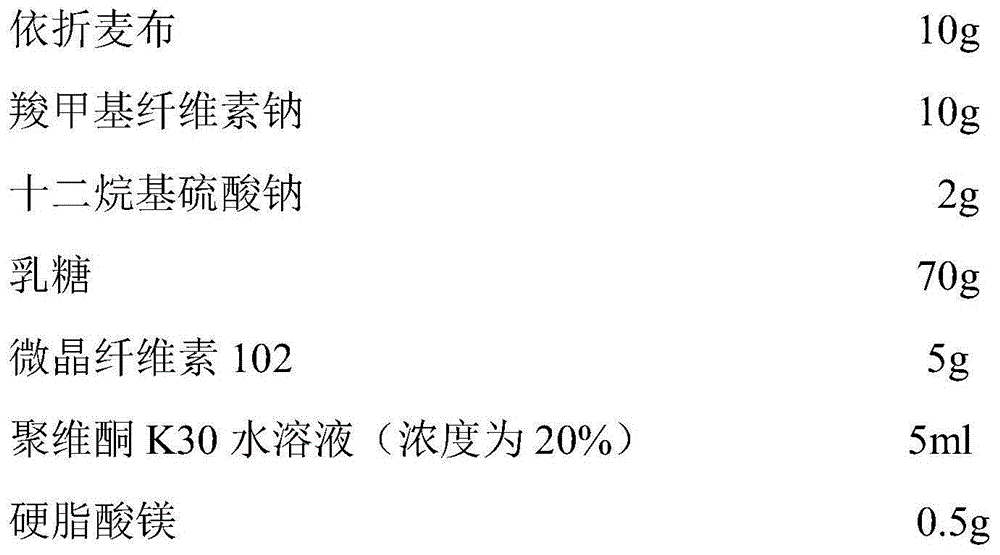

[0035] Prescription quantity: 1000 tablets

[0036]

[0037] Among them, the particle diameter D of microcrystalline cellulose 102 15 48±2.4μm, D 85 65±1.5μm, porosity (5.0±0.4)×10 -5 cm 3 / g.

[0038] Pass lactose, sodium carboxymethyl cellulose and sodium lauryl sulfate through a 80-mesh sieve (sodium lauryl sulfate should be crushed if necessary), and microcrystalline cellulose 102 and magnesium stearate through a 60-mesh sieve respectively net; the sodium lauryl sulfate, sodium carboxymethyl cellulose and ezetimibe of prescription quantity are added in the mixer successively, mix 5min and mix evenly to obtain mixed powder, then the mixed powder is passed through 40 mesh sieves; then Add lactose in equal increments; transfer the mixed powder to the wet granulator, set the stirring and chopping speed, and mix for 10 minutes; set the stirring and chopping speed, start the wet mixing granulator, and start spraying the poly Vitone K30 aqueous solution, the spray time is...

Embodiment 3

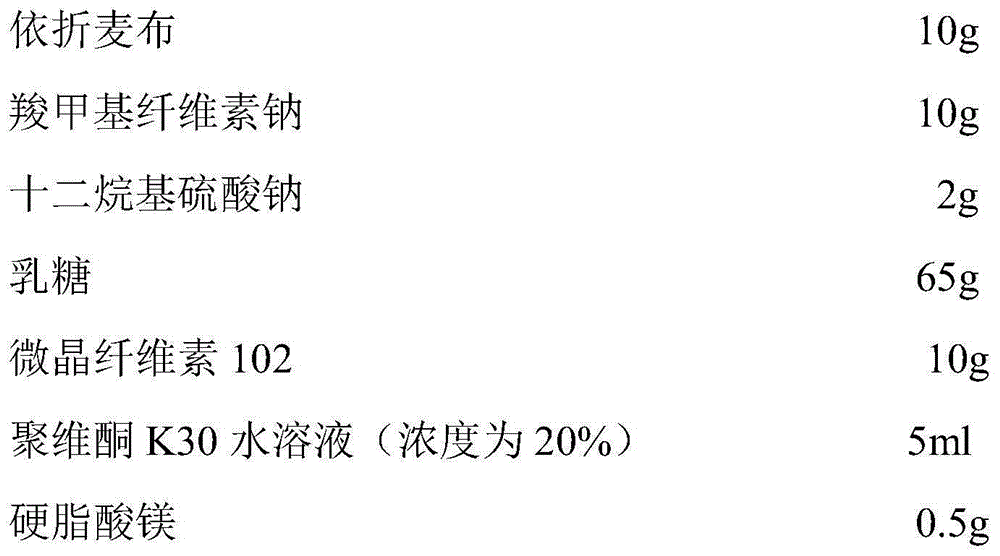

[0040] Prescription quantity: 1000 tablets

[0041]

[0042] Among them, the particle diameter D of microcrystalline cellulose 102 15 48±2.4μm, D 85 65±1.5μm, porosity (5.0±0.4)×10 -5 cm 3 / g.

[0043] Pass lactose, sodium carboxymethyl cellulose and sodium lauryl sulfate through a 80-mesh sieve (sodium lauryl sulfate should be crushed if necessary), and microcrystalline cellulose 102 and magnesium stearate through a 60-mesh sieve respectively Net; Add sodium lauryl sulfate, sodium carboxymethyl cellulose and ezetimibe in the mixer in turn in the prescribed amount, mix for 5 minutes to mix evenly to obtain a mixed powder, and pass the mixed powder through a 40-mesh sieve; then pass Add lactose in equal increments; transfer the mixed powder to the wet granulator, set the stirring and chopping speed, and mix for 10 minutes; set the stirring and chopping speed, start the wet mixing granulator, and start spraying polydimensional Ketone K30 aqueous solution, the spray time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com