Finishing method of high-isolation performance non-woven fabric and high-isolation non-woven material thereof

A non-woven, high isolation technology, used in fiber processing, textiles and papermaking, etc., can solve the problems of difficult large-scale industrial production, high vacuum conditions, production environment pollution, etc., to reduce energy consumption, breathable The effect of low performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

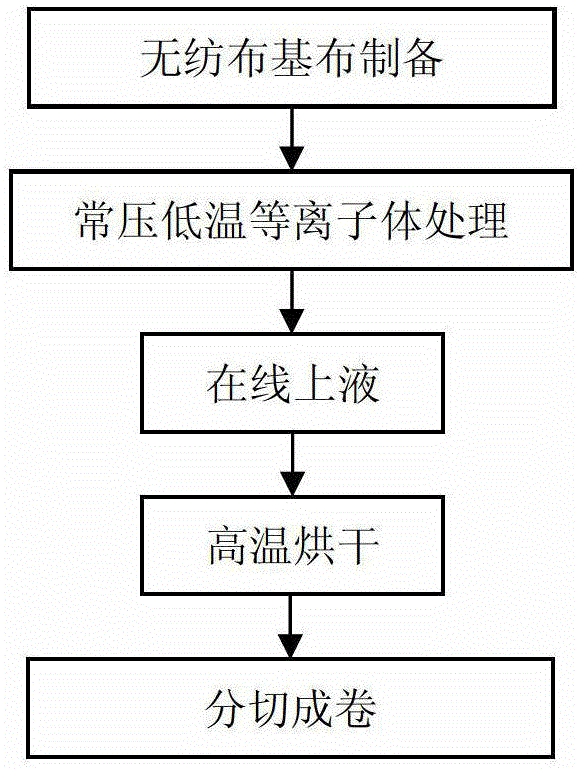

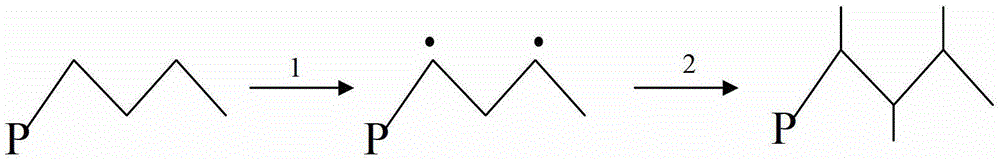

[0030] The process flow of this example is as follows figure 1 As shown, polypropylene particles with a melt index of 20-80g / 10min and a melt index of 800-1500g / 10min are used as the main raw materials of the non-woven spunbond layer and the meltblown layer respectively, and the non-woven spunbond layer is abbreviated as S layer. The melt blown layer is abbreviated as M layer. The base weight is 45gsm, and the laminated non-woven base fabric is S / M / S through melt spinning and hot rolling consolidation. Non-woven fabrics were treated with normal-pressure low-temperature plasma by ceramic electrode dielectric barrier discharge method, the discharge frequency was 150MHz, the working gas was argon, and the gas flow rate was 20FPM. The generated plasma interacts with the surface of the non-woven fabric, increasing the surface energy of the non-woven fabric and introducing reactive free radicals. After plasma surface activation, the non-woven fabric passes through the pre-configur...

Embodiment 2

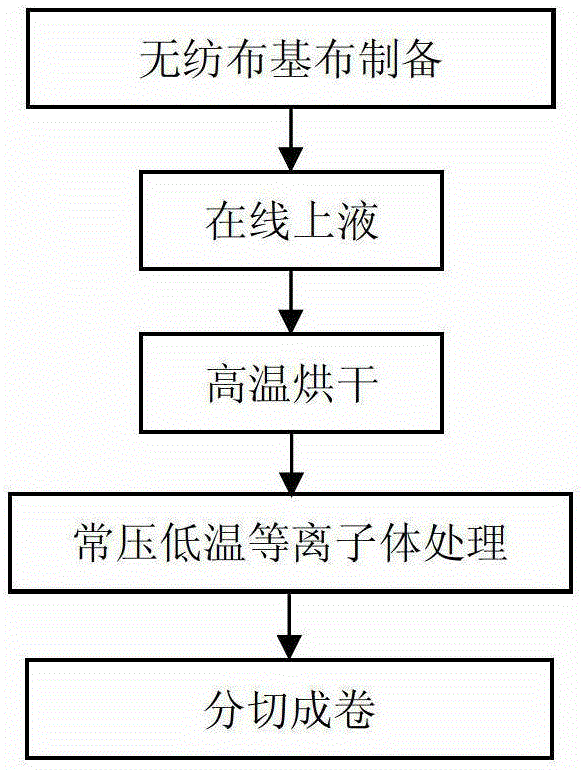

[0033] The process flow of this example is as follows figure 2 As shown, polypropylene particles with a melt index of 20-80g / 10min and a melt index of 800-1500g / 10min are used as the main raw materials of the non-woven spunbond layer and the meltblown layer respectively, and the non-woven spunbond layer is abbreviated as S layer. The melt blown layer is abbreviated as M layer. The base weight is 45gsm, and the laminated non-woven base fabric is S / M / S through melt spinning and hot rolling consolidation. The non-woven fabric passes through the pre-configured treatment solution twice successively, that is, Figure 5 As shown, it passes through two upper liquid rollers to coat the two surfaces of the non-woven base fabric respectively. The formula of the treatment liquid includes 2-(perfluorohexyl) ethyl methacrylate monomer, the concentration is 10wt%; the emulsifier is lauryl polyoxyethylene ether, the dosage is 0.8wt%, and the temperature of the treatment liquid is set at 30...

Embodiment 3

[0036] In this example, the two-component staple fiber with a ratio of polypropylene and polyethylene of 1:1 is used as the main raw material to form a spunbond layer as the upper surface layer and the lower surface layer. The spunbond layer is abbreviated as ES layer; and the melt index is 800- The meltblown layer prepared with 1500g / 10min polypropylene particles as the main raw material is used as the middle layer, and the meltblown layer is abbreviated as M layer. After short fiber laying, melt spinning, short fiber laying and hot air consolidation, a non-woven base fabric with a basis weight of 50gsm and laminated ES / M / ES is formed. Helium was used as the working gas, and the finishing methods of Example 1 and Example 2 were repeated respectively to prepare non-woven fabric materials with high isolation performance.

[0037] The isolation performance of the nonwoven fabric with high isolation performance prepared in this example can meet the requirements of use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com