Fabric-based flexible supercapacitor and its manufacturing method

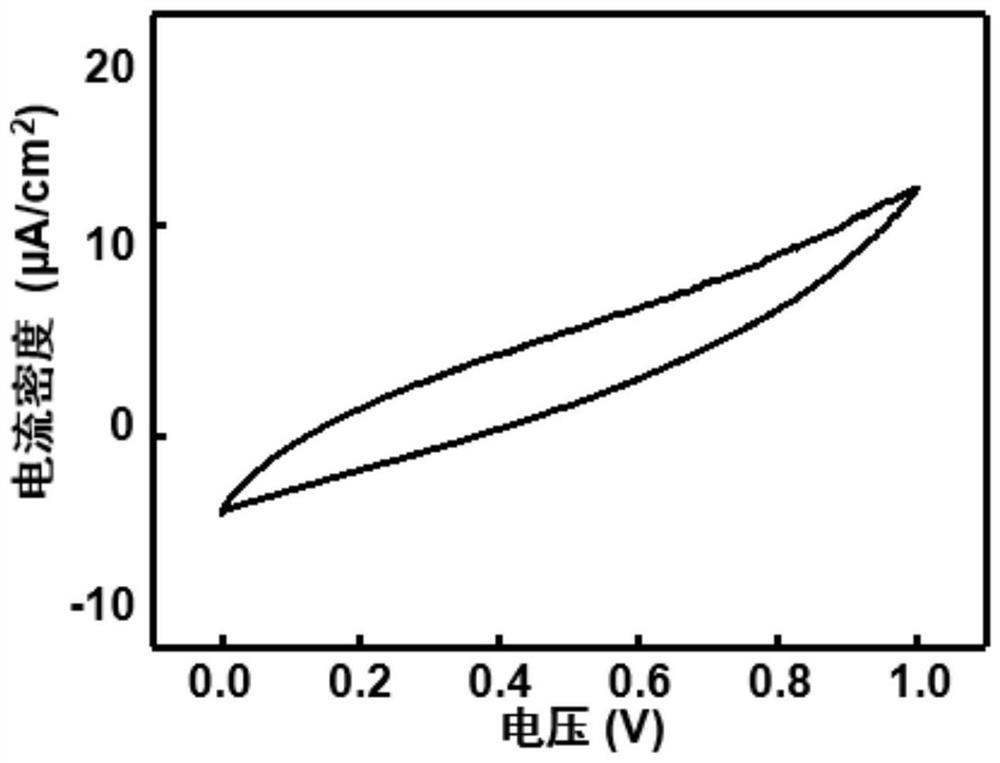

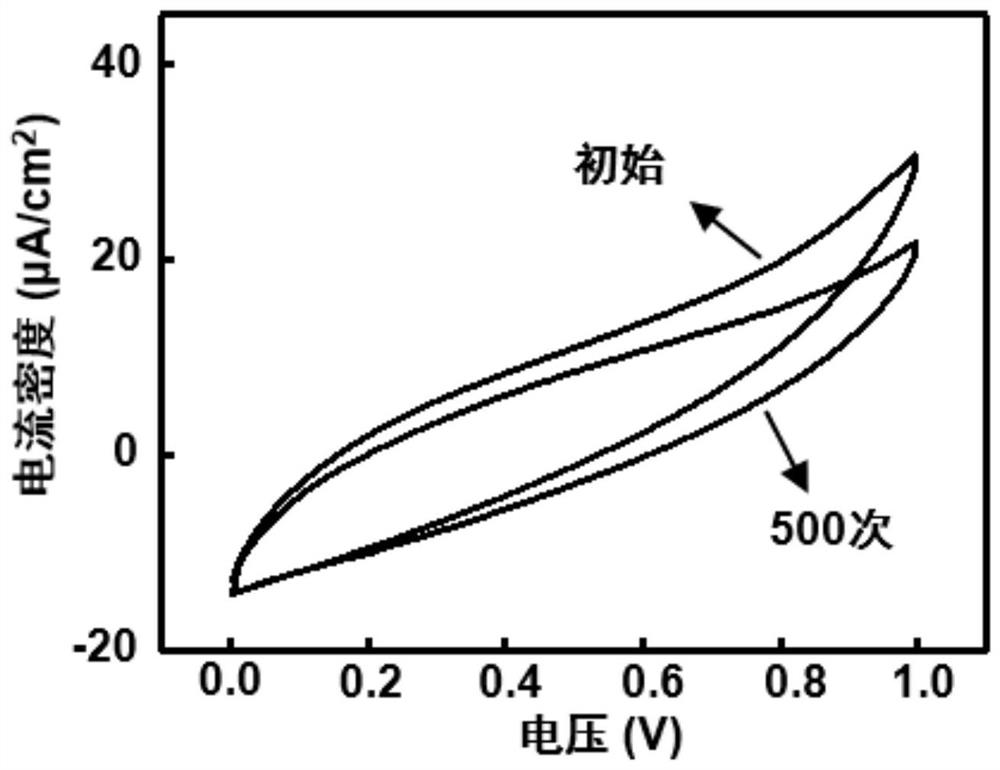

A technology for supercapacitors and manufacturing methods, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors. It can solve the problems of complex electrode manufacturing process, affecting the service life of devices, and the influence of flexible fabrics, and achieve excellent specific capacitance and bending. Folding stability, long service life, and little effect on air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Weigh 0.3 g of ammonium molybdate and 1.5 g of carboxymethyl cellulose in a beaker, add 60 g of deionized water, and stir with a magnetic stirrer until uniformly dissolved to obtain a molybdenum-containing coating solution in a gel state.

[0073] Next, prepare a clean 10cm×10cm cotton cloth as a fabric, uniformly coat the molybdenum-containing coating solution obtained above on one side of the cotton cloth by the doctor blade coating method, then put it in an oven, and dry it at 60 ° C for 4 hours , drying and curing the molybdenum-containing coating liquid, thereby obtaining a fabric with a molybdenum-containing coating.

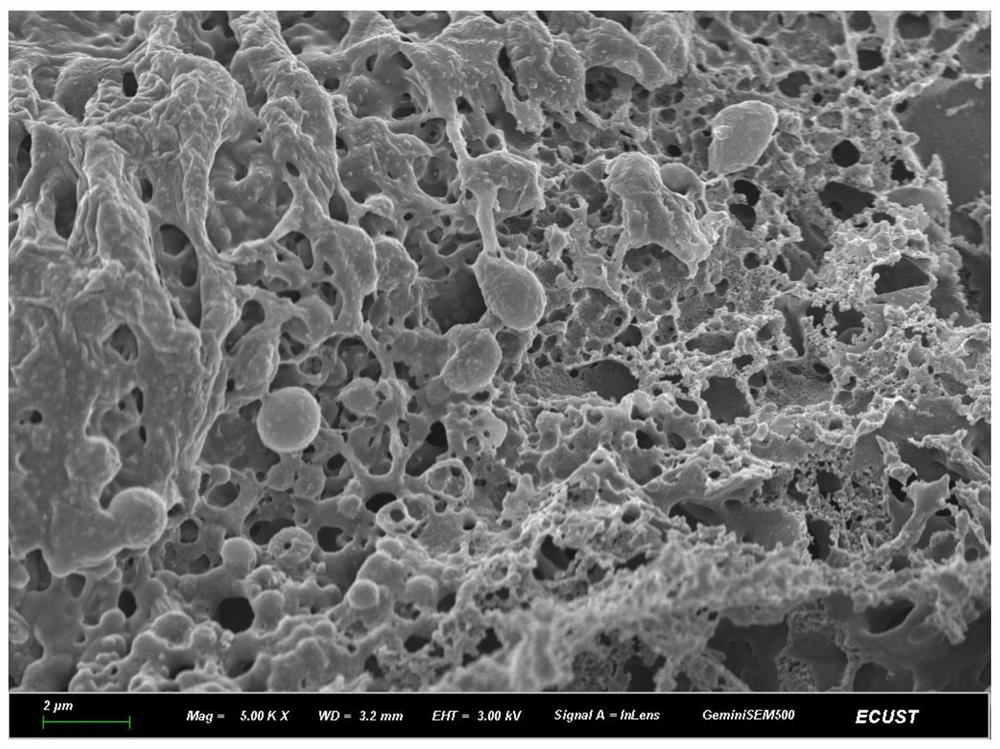

[0074] Next, use a green laser with a laser wavelength of 532 nm to perform laser direct writing on the obtained fabric with molybdenum-containing coating, and the laser irradiation conditions are set as: the laser power is 0.25 W, and the scanning speed is 2.5 mm / s. By laser irradiation, the carboxymethyl cellulose in the molybdenum-containing coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com