Preparation method of a manganese-based dust removal and denitrification integrated functional filter material

A filter material and denitrification technology, which is applied in the field of air pollution control, can solve the problems of unsuitability for industrial production, easy pulverization and falling off, and weak bonding between catalyst active components and filter material, achieving tight bonding, simple process, The effect of high denitrification activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

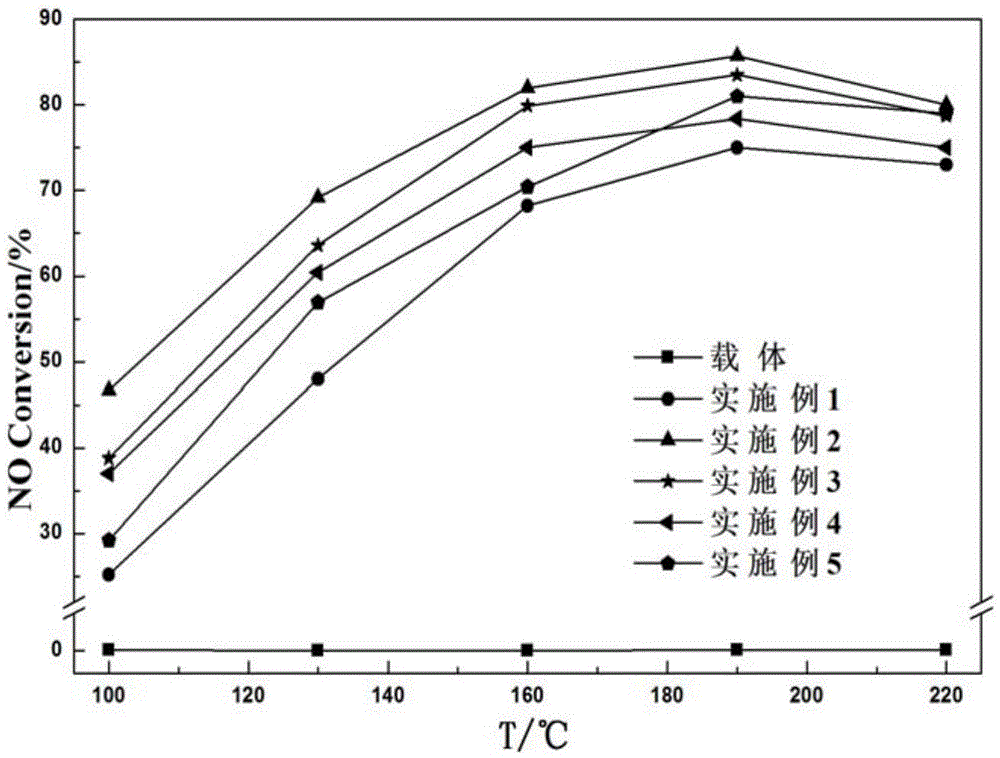

Examples

Embodiment 1

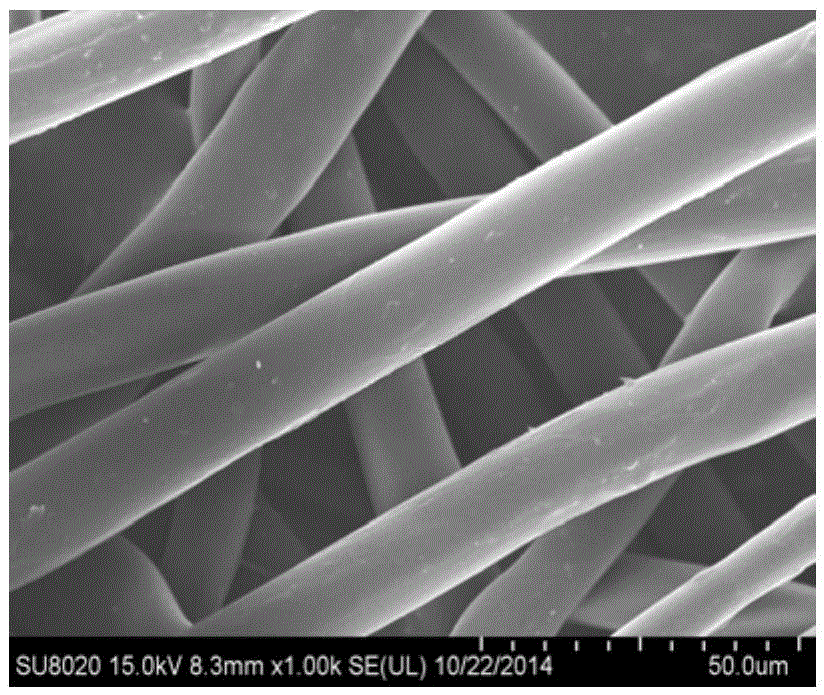

[0027] 1. Cut the polyphenylene sulfide (PPS) filter material.

[0028] 2. Preparation of silicone-modified polyurethane solution:

[0029] In the first step, add 0.71g of dimethyldiethoxysilane, 4.05g of phenyltriethoxysilane, and 0.4g of methyltriethoxysilane into a three-necked flask equipped with a magnetic stirrer, a reflux condenser, and a thermometer. Mix with 1g of water, reflux at 70°C for 4 hours, heat up to 90°C after the mixed solution becomes a homogeneous phase, distill off most of the ethanol, and then synthesize the organosilicon oligomer.

[0030] Step 2: Add 0.5 g of polyester polyol (hydroxyl value: 400 mgKOH / g) to the three-necked flask containing the silicone oligomer, react at 150° C. for 3 h, and dealcoholize to obtain a prepolymer.

[0031] The third step: add 0.3 g of diphenylmethane diisocyanate (MDI) and 2 mL of formamide to the prepolymer prepared in the previous step, and react for 2 h. Then add 20mL formamide and stir well until the solution is ...

Embodiment 2

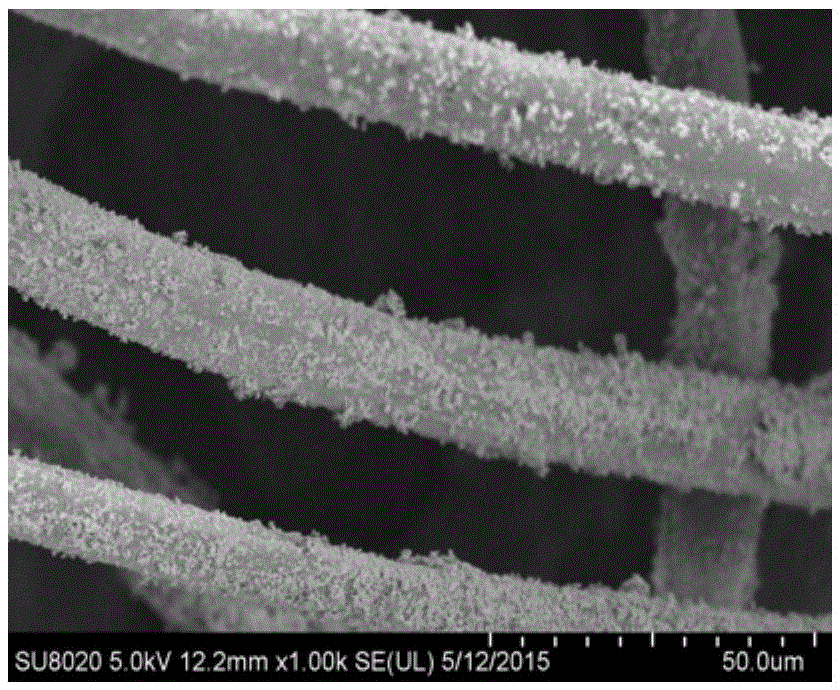

[0038] 1. Measure a certain amount of the silicone-modified polyurethane binder solution prepared in Example 1, add formamide to prepare a solution with a solid content of 0.1, then immerse the dust removal filter material (PPS filter material) in the solution for 30 minutes . Take out the dust-removing filter material after impregnation, drain it, and dry it at 90°C for 30 minutes to obtain a viscous filter material;

[0039] 2. Weigh a certain amount of manganese oxide powder prepared in Example 1, and prepare an active component suspension with a solid-to-liquid ratio of 0.07 g / mL with water. Immerse the viscous filter material prepared in step 1 into the active component suspension, and immerse for 15 minutes under the condition of ultrasonic assistance. Take out the filter material, drain, and dry at 110°C for 3h, and at 180°C for 20h. The target product is obtained.

Embodiment 3

[0041] 1. Measure a certain amount of the silicone-modified polyurethane binder solution prepared in Example 1, add formamide to prepare a solution with a solid content of 0.1, then immerse the dust removal filter material (PPS filter material) in the solution for 30 minutes . Take out the dust-removing filter material after impregnation, drain it, and dry it at 90°C for 30 minutes to obtain a viscous filter material;

[0042]2. Weigh a certain amount of manganese oxide powder prepared in Example 1, and prepare an active component suspension with a solid-to-liquid ratio of 0.09 g / mL with water. Immerse the viscous filter material prepared in step 1 into the active component suspension, and immerse for 15 minutes under the condition of ultrasonic assistance. Take out the filter material, drain, and dry at 110°C for 3h, and at 180°C for 20h. The target product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com