Two-component general-purpose water-based heat-sealing adhesive for medical device packaging and preparation method thereof

A medical device, a general-purpose technology, applied in adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of dialysis paper that is difficult to have the same quality and specifications, the air permeability of dialysis paper is reduced, and the amount of glue is large. To achieve the effect of easy gas sterilization operation, excellent storage stability, and less impact on air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

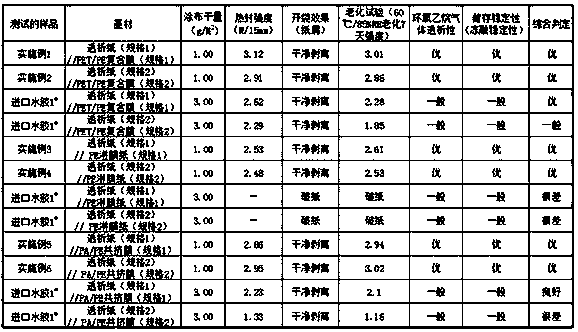

Examples

Embodiment 1

[0048] This embodiment relates to a water-based heat-sealing adhesive for medical device packaging based on a two-component general-purpose type and a preparation method thereof. The formula is shown in Table 1. The method includes the following process steps:

[0049] Manufacture of component A: After mixing the modified polyolefin water-based resin liquid, polyester water-based resin emulsion and polycarbonate polyurethane evenly, add water-based additives, then add diluent deionized water, keep stirring at high speed for 30 minutes, Check the solid content of the product, after standing for 1 hour, filter and pack;

[0050] Manufacture of component B: Mix SBS water-based resin emulsion, low-density polyethylene wax emulsion, and styrene acrylate spherical hollow polymer emulsion evenly, then add water-based additives, then add diluent deionized water, and keep stirring at high speed for 30 minutes Finally, check the solid content of the product, and after standing for 1 hou...

Embodiment 2

[0054] The formula is shown in Table 1, and the preparation method is the same as in Example 1.

Embodiment 3

[0056] The formula is shown in Table 1, and the preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com