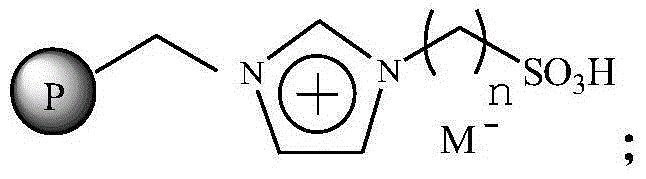

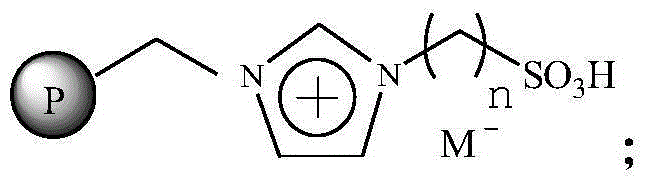

Immobilized ionic liquid catalyst and application thereof

A technology of ionic liquids and catalysts, applied in the field of immobilized ionic liquid catalysts, can solve the problems of reduced catalytic efficiency of catalysts, and achieve the effects of easy separation, high selectivity, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]Add 47.0 grams of styrene, 2.3 grams of divinylbenzene, 25 grams of polystyrene and 1.6 grams of benzoyl peroxide initiator in a 500 milliliter three-necked flask, stir and react for 2.0 hours at 60°C; then add 0.6 grams of multilayer Graphene, continue stirring for 1 hour for pre-polymerization. 260 mL of deionized water in which 2.0 g of gelatin had been dissolved was added. Adjust the stirring speed, and at the same time gradually raise the temperature to 80°C, and react for 5 hours; then raise the temperature to 90°C, react for 5 hours, and finally raise the temperature to 98°C, and react for 6 hours. After the reaction, pour out the upper liquid, wash it with hot water at 85°C for several times, then wash it with cold water for several times, then filter it, put it in an oven for drying at 80°C, and sieve it to collect the particle size within the range of 0.35-0.60mm Composite macroporous microsphere A.

[0041] Chloromethylation of composite macroporous microsph...

Embodiment 2

[0046] Add monomer mixture solution (60.0 gram styrene, 1.0 gram divinylbenzene, 60 gram polystyrene, 1.6 gram multilayer graphene and 1.0 gram benzoyl peroxide containing initiator in 500 milliliters of there-necked flasks, the The solution was first stirred and reacted at 70°C for 0.5 hours), the stirrer was started, a mixed solution of 200 ml of deionized water and 4 grams of polyvinyl alcohol was added, the temperature was raised to 85°C, and the reaction was carried out for 3 hours, then the temperature was raised to 90°C, and the reaction was carried out for 9 hours. Finally, the temperature was raised to 100° C., and the reaction was carried out for 10 hours. After the reaction, pour out the upper liquid, wash with 85°C hot water, then wash with cold water, then filter, put in an oven to dry at 80°C, sieve, and collect composite macropores with a particle size within the range of 0.35 to 0.60 mm Microspheres B.

[0047] Chloromethylation of composite microspheres: In a...

Embodiment 3

[0052] Change the anion in [Example 1] (using p-toluenesulfonic acid, the consumption is equimolar with the compound imidazolium cationic microsphere A), all the other preparation conditions are the same as [Example 1], finally obtain Cat-C, its structural formula is

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com