Water-soluble copolyester and preparation method thereof

A copolyester, water-soluble technology, applied in the field of preparation of water-soluble copolyester, achieves the effects of good water-soluble stability and excellent water-solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

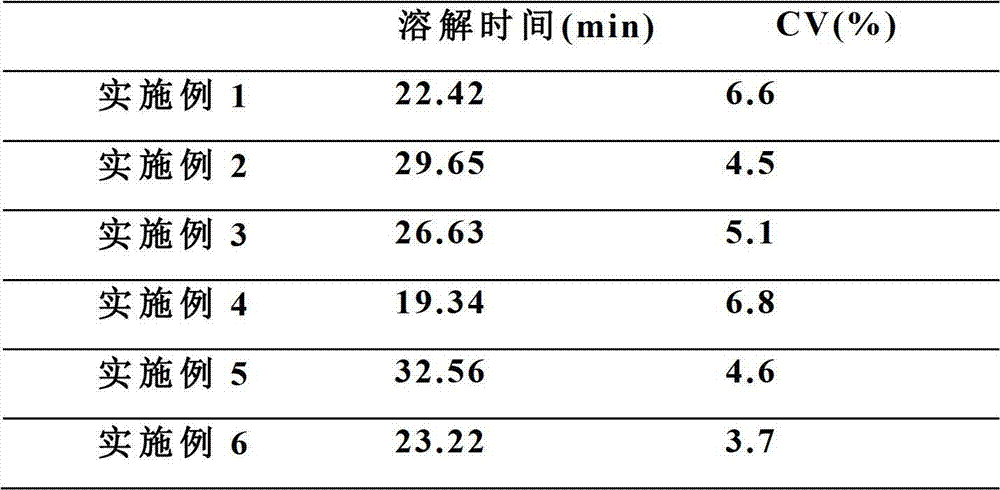

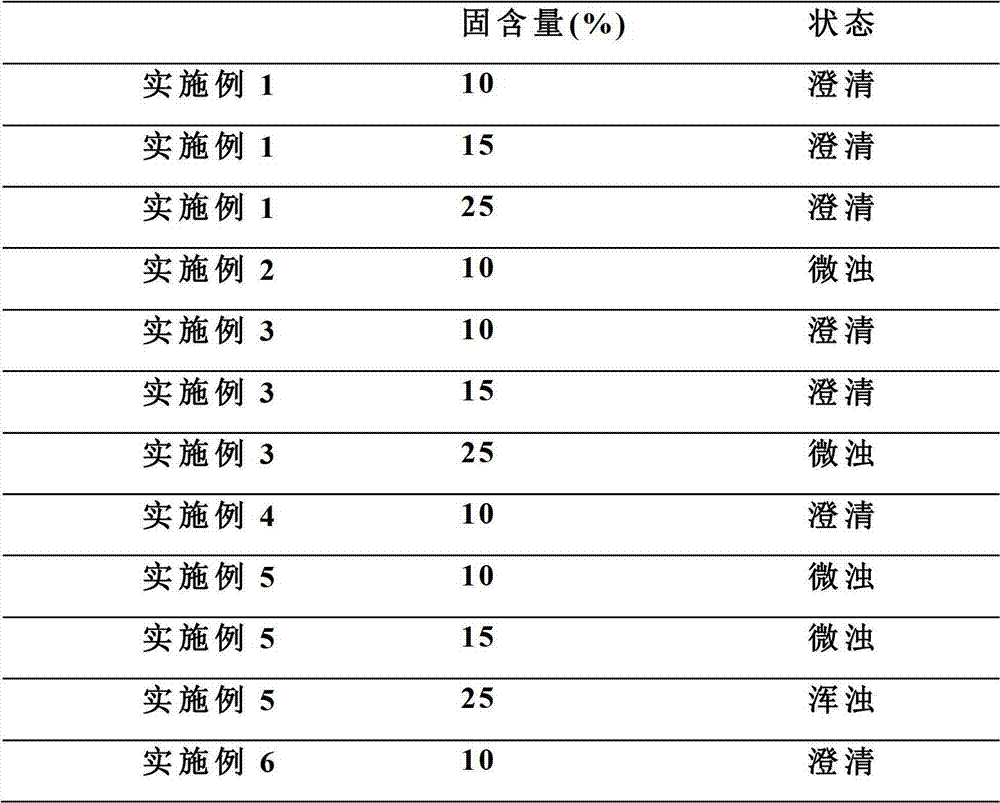

Examples

Embodiment 1

[0030] Put 2.66kg of isophthalic acid, 4.74kg of dimethyl isophthalate-5-sodium sulfonate, 19.84kg of ethylene glycol and 19.97kg of furandicarboxylic acid into a 100L stainless steel reaction kettle, and add 30g of zinc acetate, 20g of tetrabutyl titanate, under nitrogen system, heat up to 180-200°C for 1.5 hours, then gradually raise the temperature to 220-240°C for 3.5 hours, when the amount of by-products collected reaches 5.9kg, the esterification reaction ends. Add 28g of antimony acetate and 13g of triphenyl phosphate, and gradually reduce the pressure to below 100Pa within 0.5 hours to carry out polycondensation reaction. The polymer product was obtained after 5 hours of reaction.

[0031] The product is analyzed by DSC, and the measured glass transition temperature (Tg) is 46°C; at 35°C, the intrinsic viscosity is 0.44dL / g;

Embodiment 2

[0033]Put 15.96kg of terephthalic acid, 2.66kg of isophthalic acid, 4.74kg of dimethyl isophthalate-5-sodium sulfonate, 14.88kg of ethylene glycol and 4.99kg of furandicarboxylic acid into a 100L stainless steel reaction kettle , and add 30g of zinc acetate and 20g of tetrabutyl titanate. Under nitrogen system, raise the temperature to 180-200°C for 1 hour, and then gradually raise the temperature to 220-240°C for 2.5 hours. When the amount of by-products collected reaches 5.9kg When the esterification reaction ends. Add 28g of antimony acetate and 13g of triphenyl phosphate, and gradually reduce the pressure to below 100Pa within 0.5 hours to carry out polycondensation reaction. The polymer product was obtained after 4 hours of reaction.

[0034] The product is analyzed by DSC, and the measured glass transition temperature (Tg) is 50°C; at 35°C, the intrinsic viscosity is 0.39dL / g;

Embodiment 3

[0036] Put 10.64kg of terephthalic acid, 2.66kg of isophthalic acid, 4.74kg of dimethyl isophthalate-5-sodium sulfonate, 14.88kg of ethylene glycol, 3.39kg of diethylene glycol and 9.98kg of furandicarboxylic acid into the In a 100L stainless steel reaction kettle, add 30g of zinc acetate and 20g of tetrabutyl titanate. Under a nitrogen system, raise the temperature to 180-200°C for 1.5 hours, then gradually raise the temperature to 220-240°C for 3 hours. When collected The esterification reaction ended when the by-product amount reached 5.9 kg. Add 28g of antimony acetate and 13g of triphenyl phosphate, and gradually reduce the pressure to below 100Pa within 0.5 hours to carry out polycondensation reaction. The polymer product was obtained after 4.5 hours of reaction.

[0037] The product is analyzed by DSC, and the measured glass transition temperature (Tg) is 43°C; at 35°C, the intrinsic viscosity is 0.42dL / g;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com