Method for producing ultrahigh-viscosity refined cotton

A technology for refining cotton and viscosity, which is applied in the fields of pulping with inorganic alkali, pulping of cellulose raw materials, textiles and papermaking, etc. The effect of low consumption and low water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

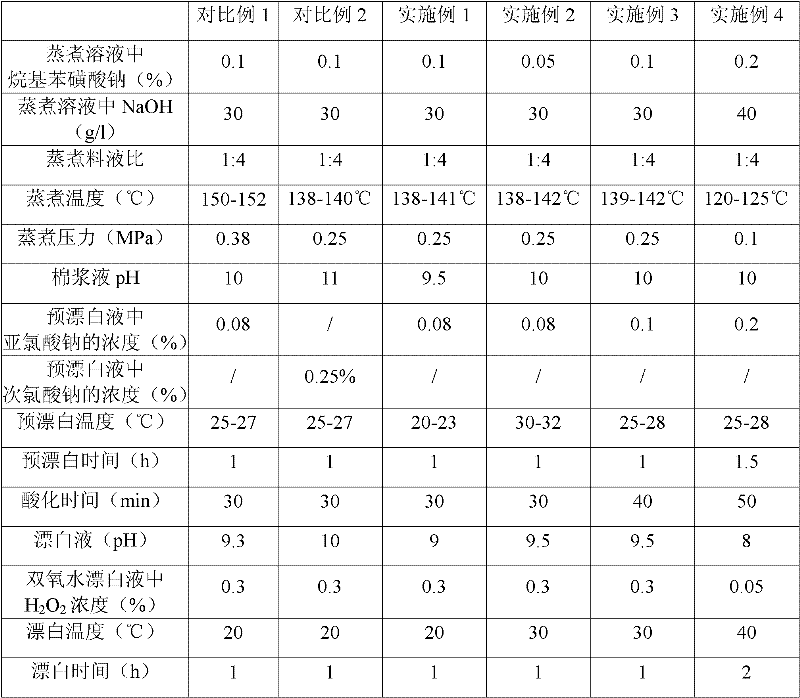

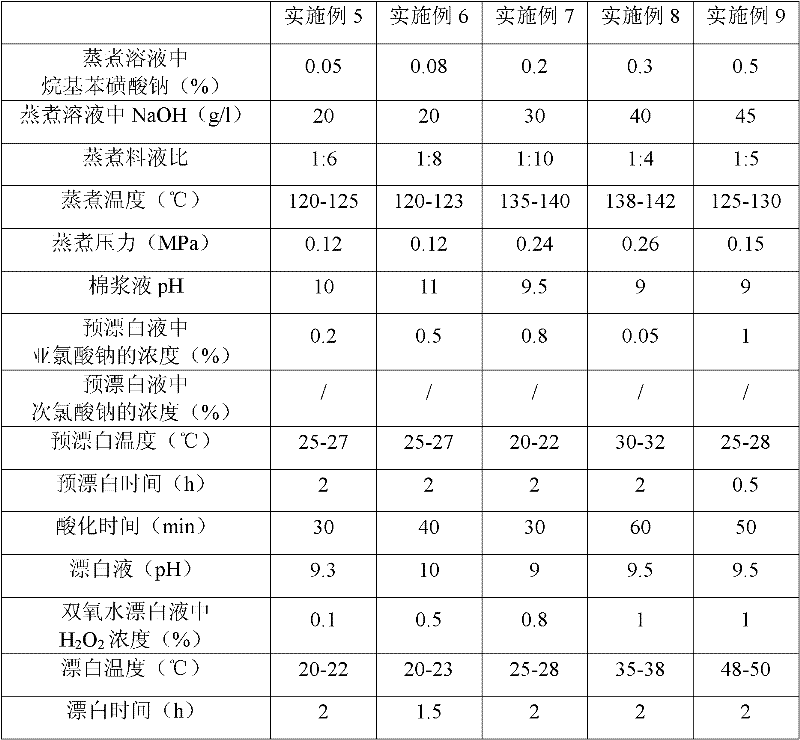

Examples

Embodiment 1

[0043] Take 300 g of cotton linters with a degree of polymerization of 2564 dp and no obvious impurities, and infiltrate it with a cooking solution. The content of NaOH in the cooking solution is 30 g / l, and the content of sodium alkylbenzene sulfonate is 0.05%. The soaked cotton linters are added to the cooking pot, and the cooking liquid is added according to the cooking liquid ratio of 1:8, the cooking pot is turned, and at the same time, the cooking liquid is heated to about 140°C with steam, and the heating time is 30 minutes. After reaching the temperature, maintain the cooking temperature at about 140°C, the cooking pressure at 0.25 MPa, and the cooking time for 2 hours; wash the absorbent cotton after cooking with tap water to remove the alkali; add tap water to the washed absorbent cotton to make the cotton-liquid ratio 3:100, Then add NaOH solution to the cotton slurry to make the pH of the cotton slurry = 9.5, then add sodium chlorite to make the concentration of sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com