Method for calculating liquid output of oil pumping unit through active power difference

A technology for active power and difference calculation, applied in measurement, earthwork drilling, wellbore/well components, etc., can solve problems such as difficult maintenance, low test accuracy, and high price, and achieve the goal of avoiding environmental interference, mature equipment technology, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

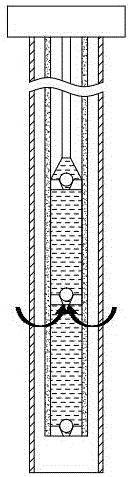

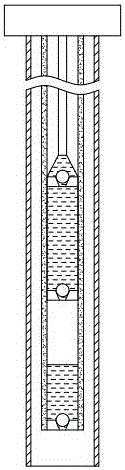

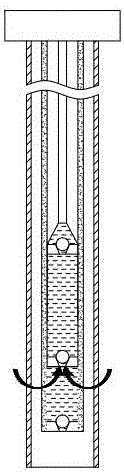

[0020] Below in conjunction with accompanying drawing, a kind of method that utilizes active power difference of the present invention to calculate the liquid production rate of pumping unit is further explained:

[0021] When there is no major change in the well conditions, it can be considered that the work done by the counterweight of the pumping unit, the work done by the friction force, the work done by the self-weight of the sucker rod, the work done by the inertial force, the work done by the wellhead back pressure, the mechanical efficiency and the motor efficiency are all important factors in the collection of active power. The time of curve II is the same as that of collecting active power curve I. Then, through the derivation process of the following formula, it can be obtained that the area integral of the downstroke active power versus time in the active power curve II is subtracted from the area integral of the downstroke active power versus time in the active pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com