Shock absorber

A buffer and component technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of insufficient damping force and unstable damping force, and achieve the goal of improving responsiveness and stabilizing damping force characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

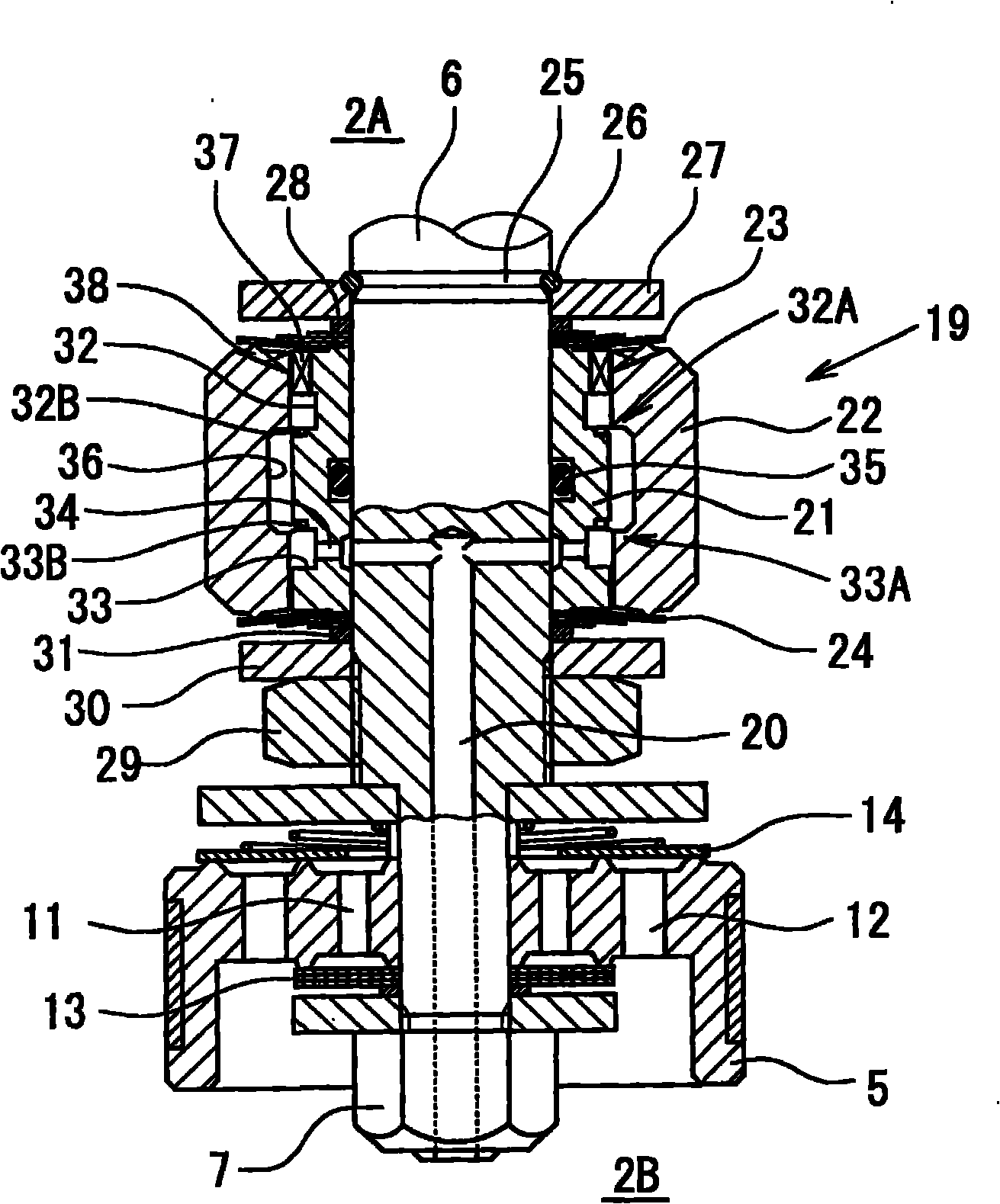

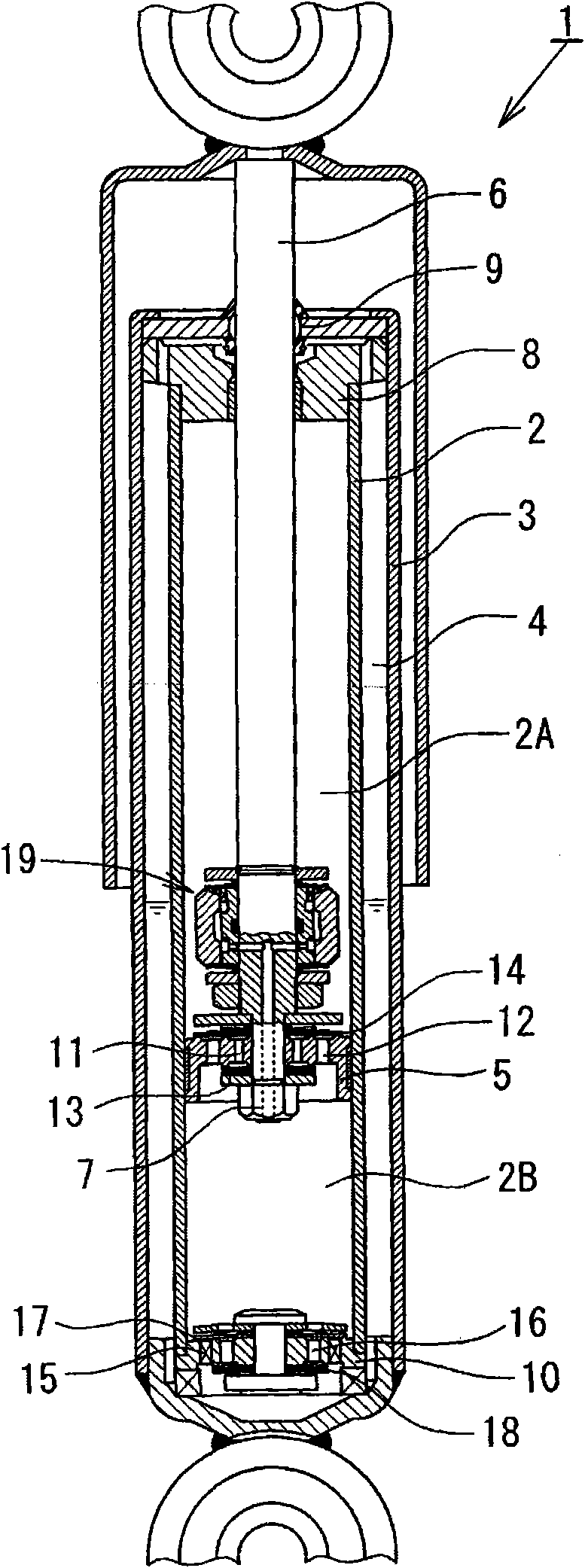

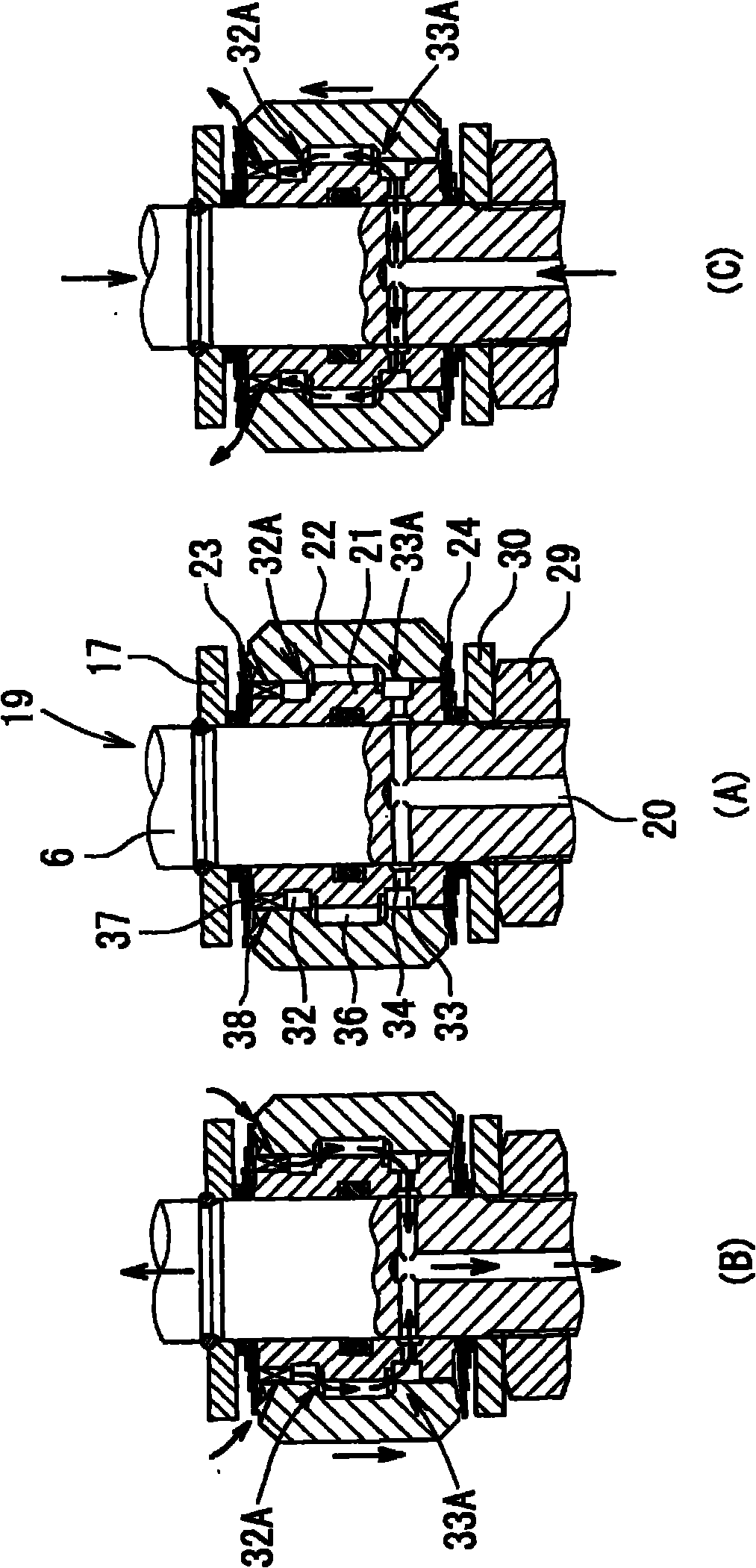

[0022] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. refer to Figure 1 to Figure 3 A first embodiment of the present invention will be described. Such as figure 1 and figure 2 As shown, the shock absorber 1 of this embodiment is a so-called double-tube type shock absorber, which constitutes the following double-tube structure, that is, an outer tube 3 is provided on the outer periphery of the cylinder body 2, and an outer tube 3 is provided between the cylinder body 2 and the outer tube 3. An annular storage chamber 4 is formed. A piston 5 is slidably inserted into the cylinder 2, and the inside of the cylinder 2 is partitioned by the piston 5 into two cylinder chambers, namely, an upper cylinder chamber 2A and a cylinder lower chamber 2B. One end of the piston rod 6 is connected to the piston 5 by a nut 7, and the other end side of the piston rod 6 can slide and liquid-tightly pass through the guide rod 8 and the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com