Speed reducer lubricating device for oilfield pumping unit

A technology of lubricating device and pumping unit, applied in transmission parts, gear lubrication/cooling, mechanical equipment, etc., can solve the problem that lubricating oil is scarce, cannot meet the lubrication of driven shaft bearings, and the oil scraper cannot normally scrape lubrication oil and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

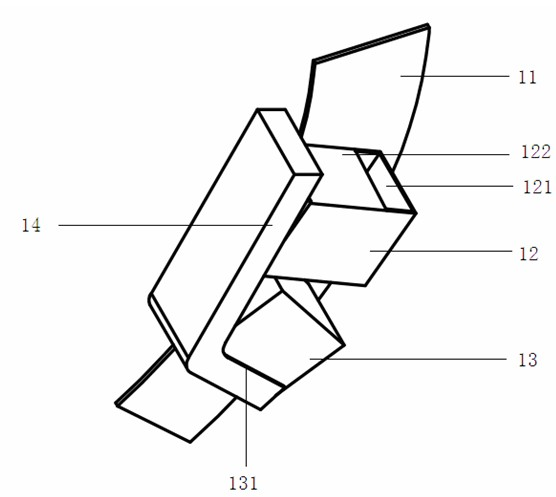

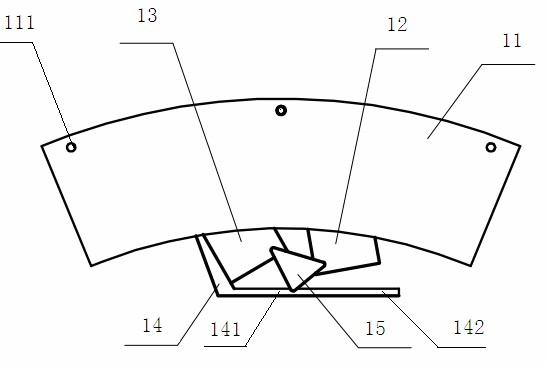

[0026] Such as figure 1 , figure 2 and Figure 6 As shown, a lubricating device for a reducer for an oil field pumping unit includes an oil lifter 1 and an oil storage pan 2; the oil lifter 1 is mainly composed of a support plate 11, a first oil box 12, a second oil box 13, an oil guide The support plate 14 is composed of several support plate mounting holes 111.

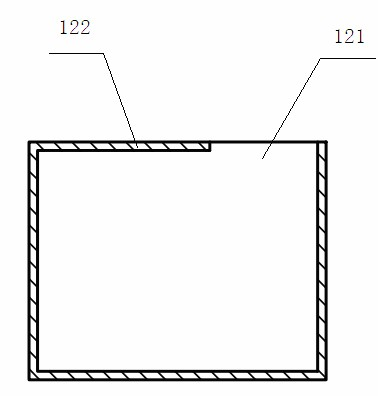

[0027] Such as figure 1 , image 3 and Figure 4 As shown, the first oil box 12 and the second oil box 13 are respectively provided with a first oil lifting port 121 and a second oil lifting port 131 on the outer side, wherein the first oil lifting port 121 is provided with a baffle plate 122 to To prevent the lubricating oil from being lost prematurely, it cannot flow into the oil storage pan 2 sufficiently, and the second oil box 13 is protected by the oil guide plate 14, so it is not necessary to inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com