Wellhead positioned integrated guide vertical well repair catwalk and application method

A directional and vertical technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of high labor intensity, cumbersome replacement process, frequent and boring movements, etc., to avoid bending deformation, avoid secondary adjustment, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

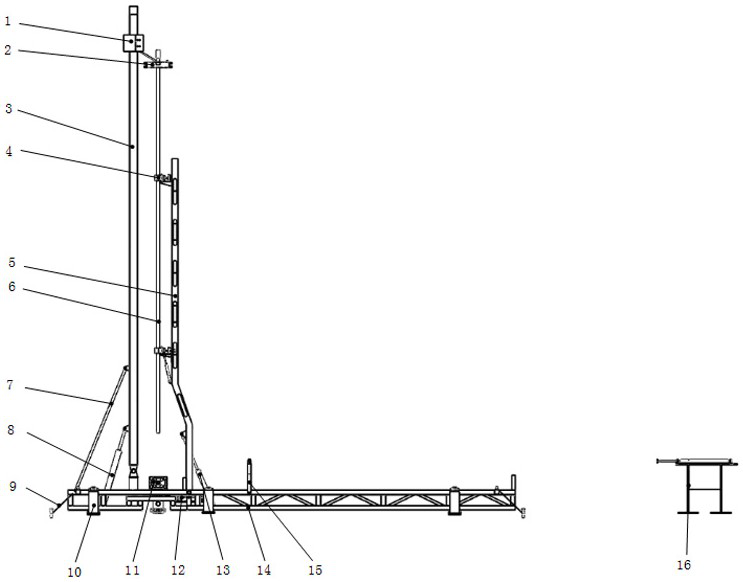

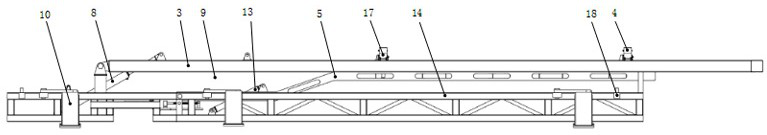

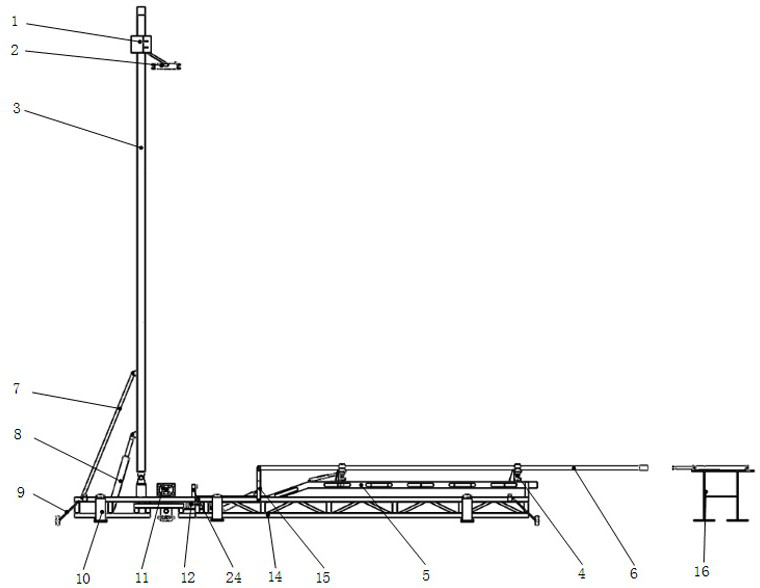

[0034]Embodiment 1, with reference to the accompanying drawings, a wellhead positioning integrated guide vertical workover catwalk mentioned in the present invention includes a base 14, a lifting arm 5, a lifting arm cylinder 13, a wellhead adjustment device 12, a guide Rod 3, first manipulator 4, second manipulator 17, hydraulic outrigger 10, ground anchor 9, guide rod cylinder 8, guide rod brace 7, measuring and positioning device 15, measuring and pushing device 16, limit device 24, base 14 There are 6 hydraulic outriggers 10 and 4 ground anchors 9 connected on both sides to support the vertical catwalk; the upper side of the base 14 is hinged with a lifting arm cylinder 13, a lifting arm 5, a guide rod 3, and a guide rod cylinder 8 , guide rod diagonal brace 7. The lifting arm cylinder 13 is hinged with the lifting arm 5, the guide rod 3 is hinged with the guide rod cylinder 8, and the guide rod brace 7 is hinged with the guide rod 3;

[0035] The lifting arm cylinder 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com