Methods, apparatus and products useful in the operation of a sucker rod pump during the production of hydrocarbons

a technology of sucker rod pump and sucker rod, which is applied in the field of methods, products and products for the production of hydrocarbons with sucker rod pumps, can solve the problems of damage to the pumping system, general cost of maintenance, and high cost of repair labor and parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described by reference to the drawings.

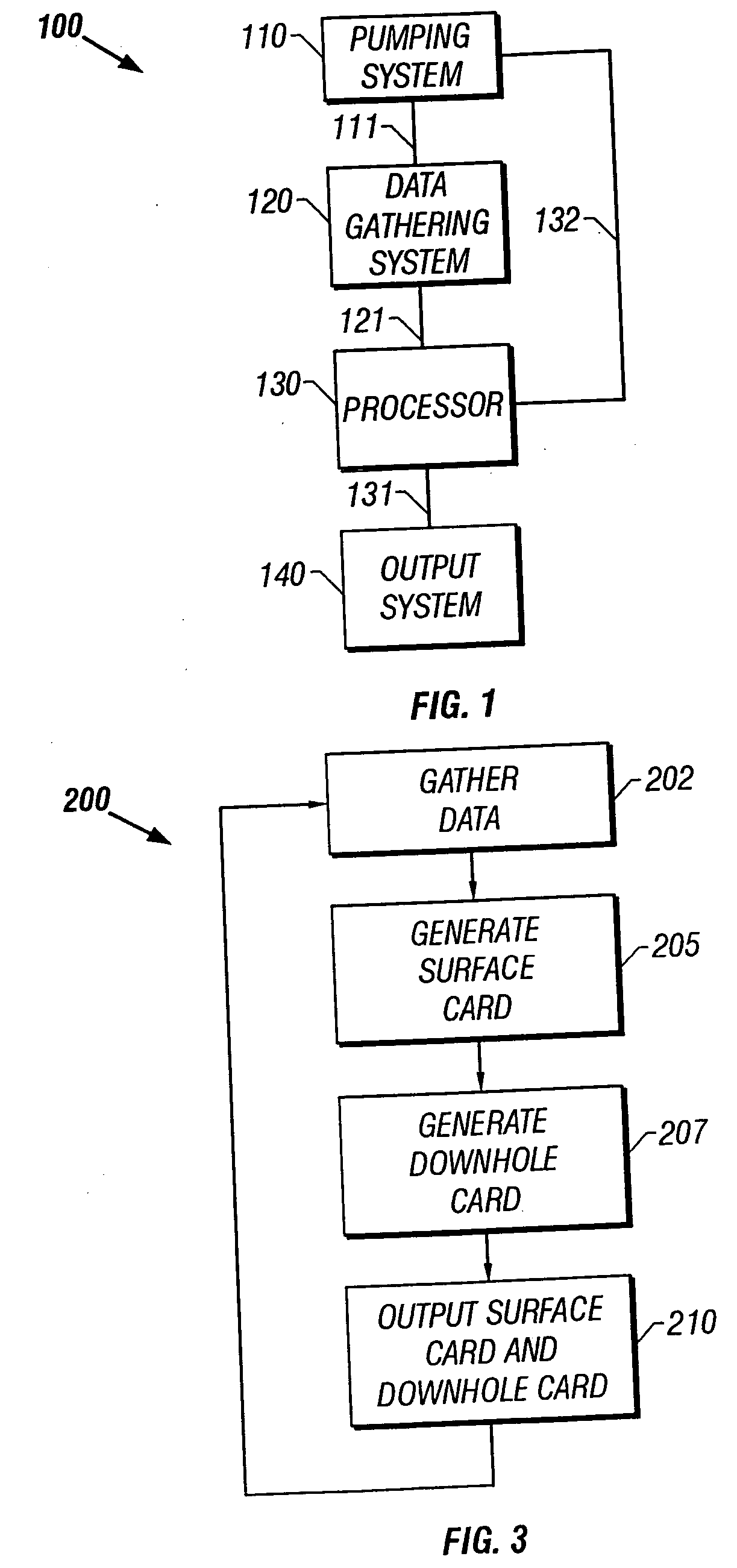

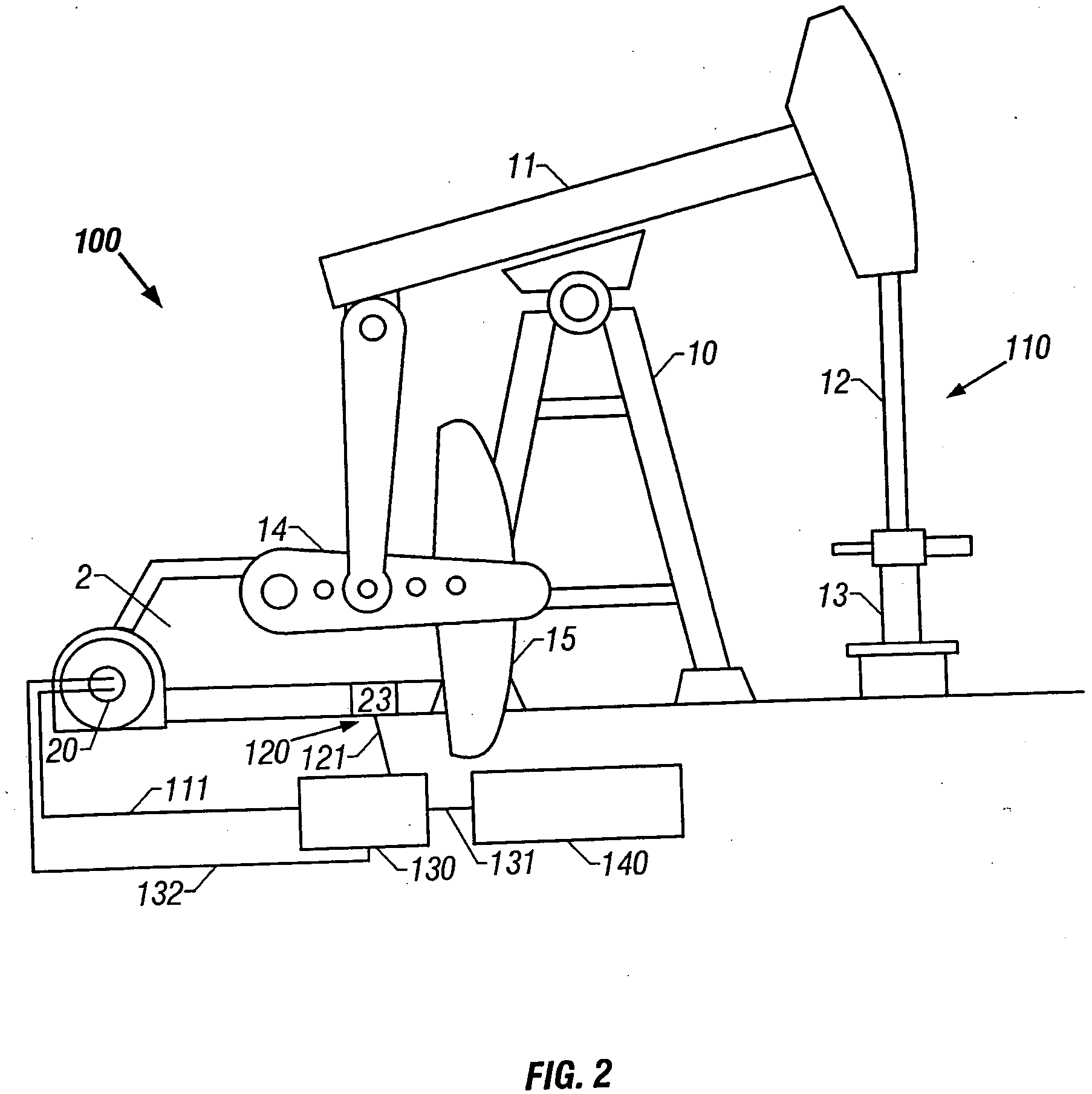

[0060] Referring first to FIG. 1, there is shown a schematic representation of well unit 100 of the present invention, including pumping system 110, data gathering system 120, processor 130, and output system 140.

[0061] Data gathering system 120 is in communication with pumping system 110 and processor 130, by communication link 111 and communication link 121, respectively. Processor 130 is in communication with output system 140 by communication link 131, and optionally in communication with pumping system 110 by communication link 132. It should be understood that communication links 111, 121, 131 and 132 can be physical wire links or may be wireless links. These links may include one or more types of links, for example, phone line, network, Internet, and wireless.

[0062] It should also be understood that while data gathering system 120, processor 130, and output system 140 are shown as separate boxes in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com