Device and method for debugging knit design and debug program

A technology in a knitted fabric and a device, which is applied in the field of debugging in the design of knitted fabrics, can solve the problems of instability, different batches of knitted yarns, and inability to detect, and achieves the effect of simplified operation and easy inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

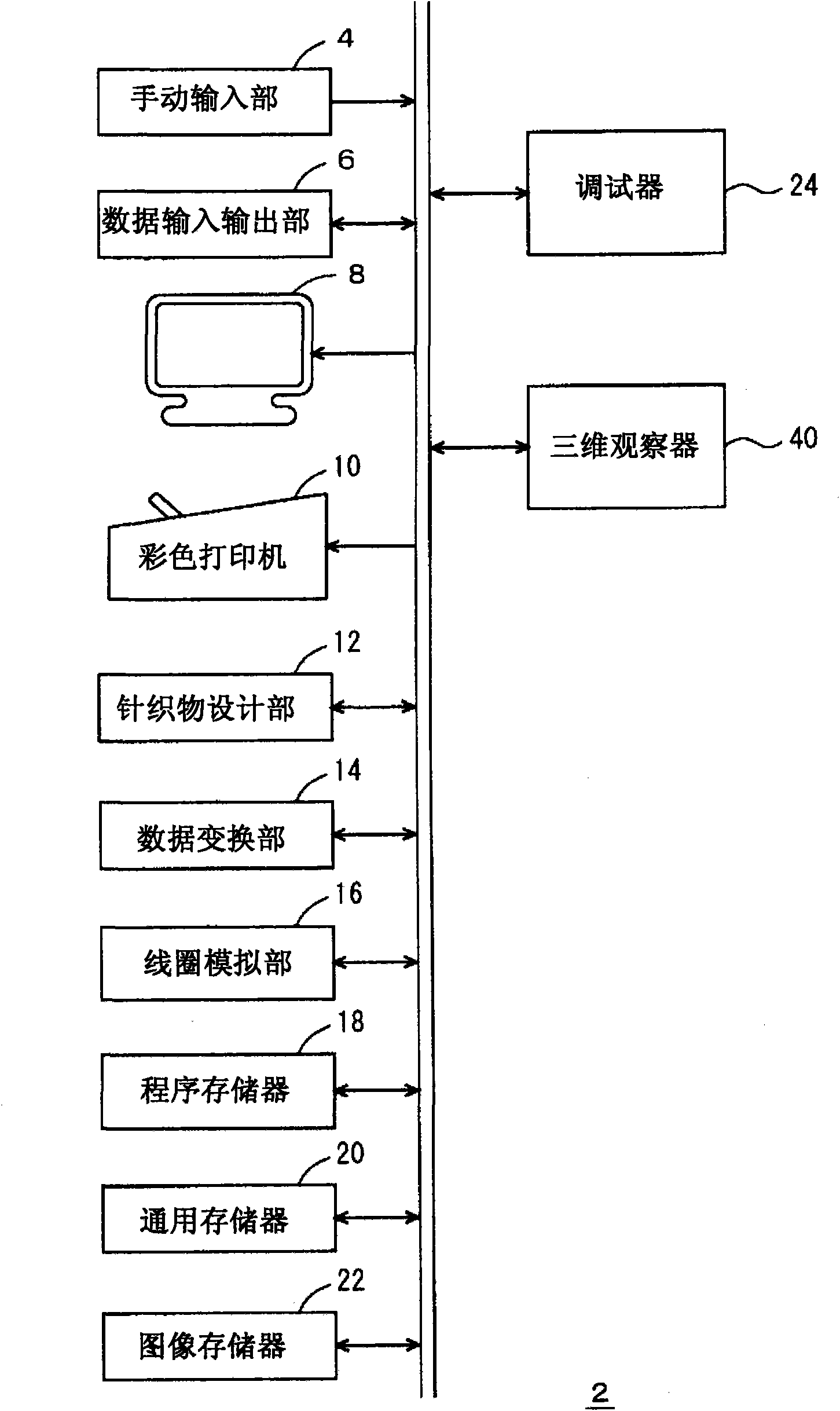

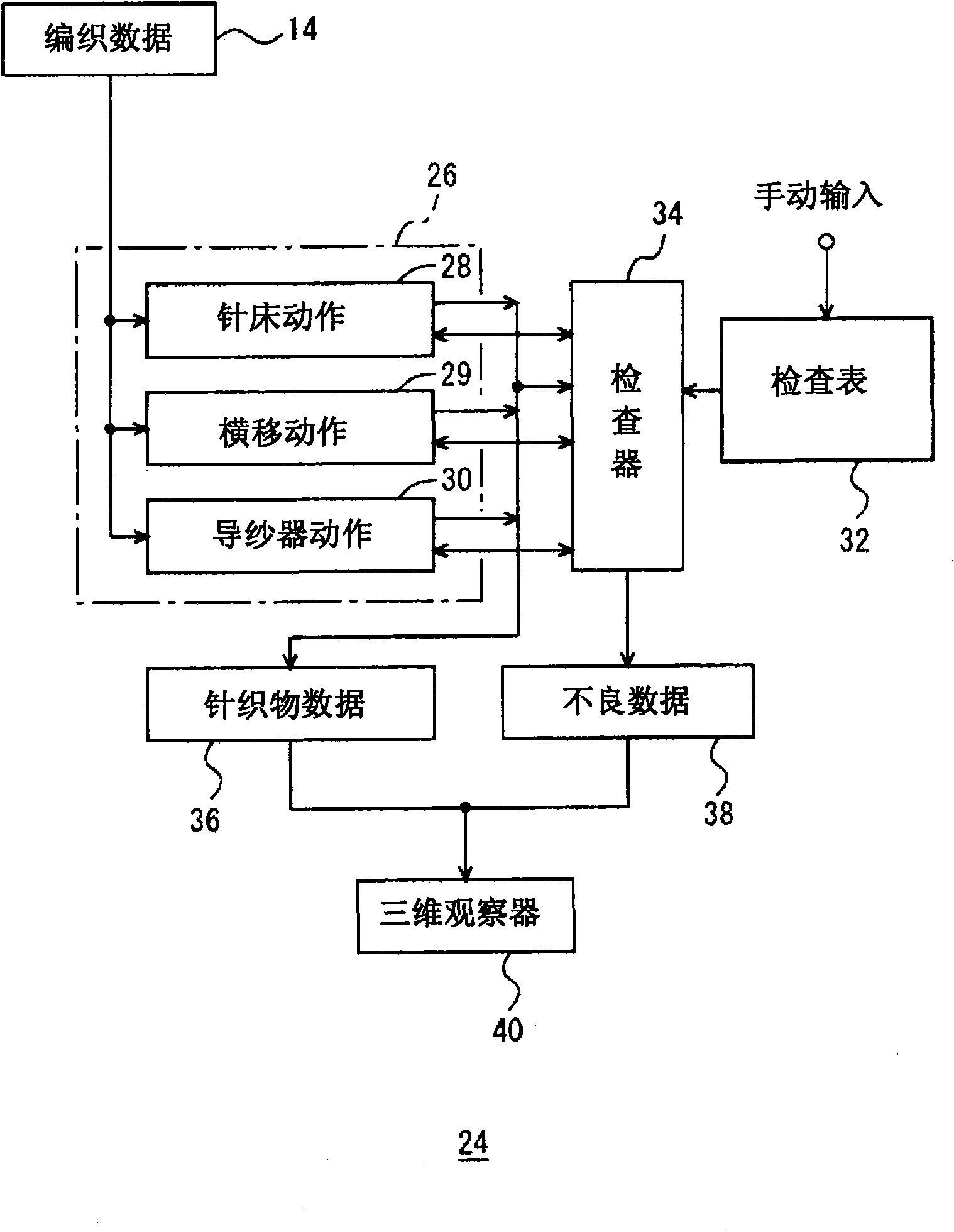

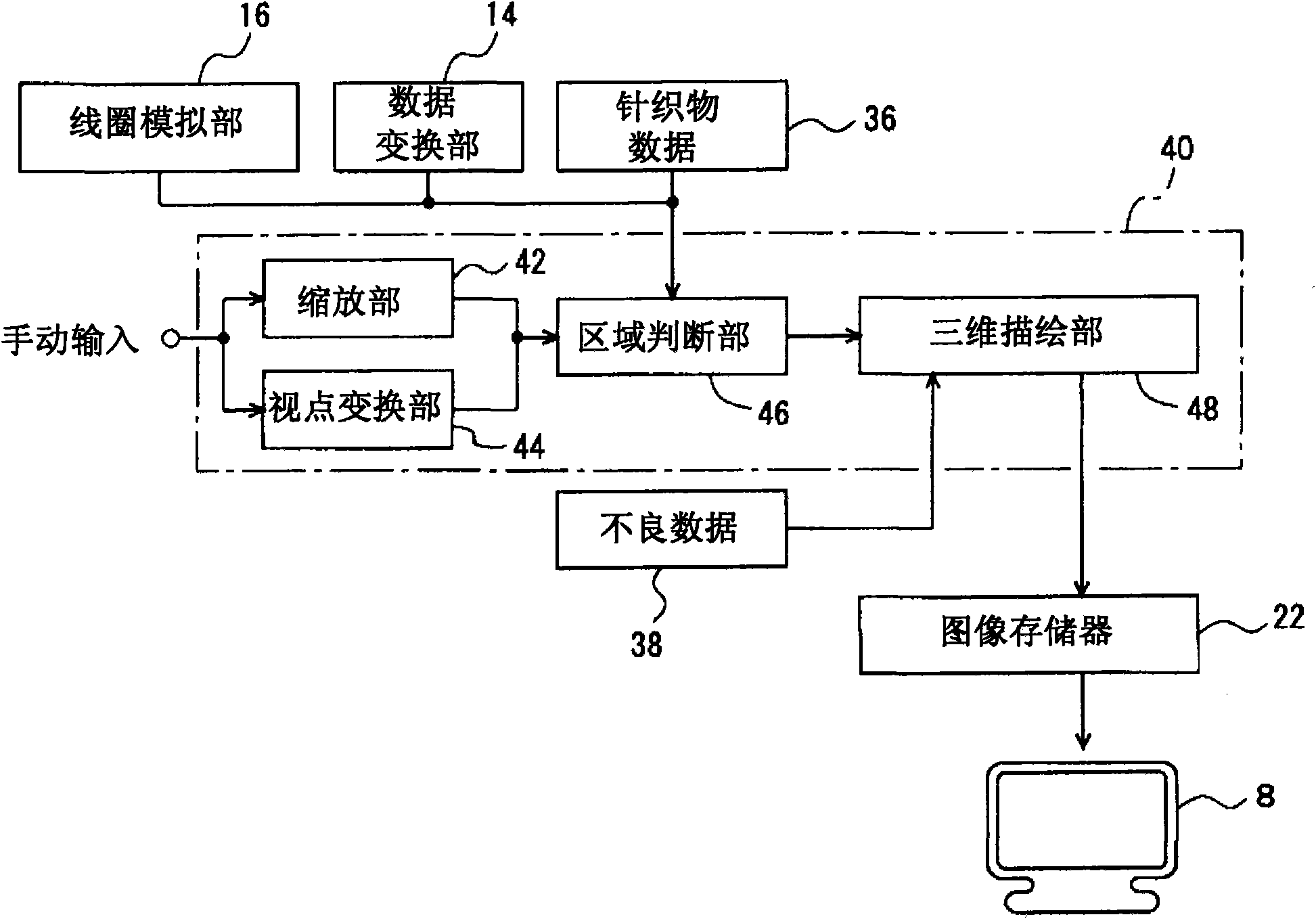

[0094] Figure 1 to Figure 13 Indicates an example. exist figure 1 Among them, 2 is a knitted fabric design device, and 4 is a manual input unit, which is a keyboard, a stylus, a mouse, a track ball, a joystick, and the like. The data input / output unit 6 inputs and outputs various data, and is composed of a disk drive, a network interface, and the like. The color monitor 8 and the color printer 10 output various data such as design data of knitted products, simulation data of completed knitted products, and images of a three-dimensional viewer described below.

[0095] The knitted fabric design unit 12 designs knitted products based on inputs from the data input and output unit 6 and the manual input unit 4 . Then, the obtained design data is converted by the data conversion unit 14 into knitting data that can be knitted by the flat knitting machine. The stitch simulation 16 generates an image of a simulated knitted fabric to display each stitch based on the knitting data....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com