Checking method of circuit substrate and checking device thereof

An inspection method and circuit substrate technology, applied in circuit inspection/identification, measuring devices, electronic circuit testing, etc., can solve problems such as complex structure and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, the present invention will be described together with examples with reference to the drawings.

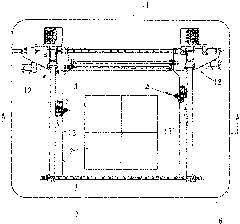

[0052] figure 2 It is a plan view of the circuit board inspection apparatus 1 of one embodiment of the present invention. image 3 yes figure 2 A-A longitudinal section view. This inspection device 1 is a continuous type (fling type) inspection device in which an inspection probe 4 is sequentially moved toward a terminal 3 on a circuit board 2 and brought into contact with the terminal 3 to perform an electrical inspection. This inspection device 1 can perform electrical inspection on both surfaces of the circuit board 2 using a plurality of inspection probes 4 arranged on the front side and the back side of the circuit board 2 . Specifically, the pair of upper inspection probes 4 is movable in the X direction, the Y direction, and the Z direction above the base 6 held horizontally at a predetermined height by the support legs 5, and the pair of lower inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com