Husker

A technology of rice huskers and rubber rollers, which is applied in the field of rice huskers. It can solve the problems of time-consuming operation and the heavy weight of rubber roller replacement operations, so as to improve the processing capacity of huskers and reduce the generation of broken rice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

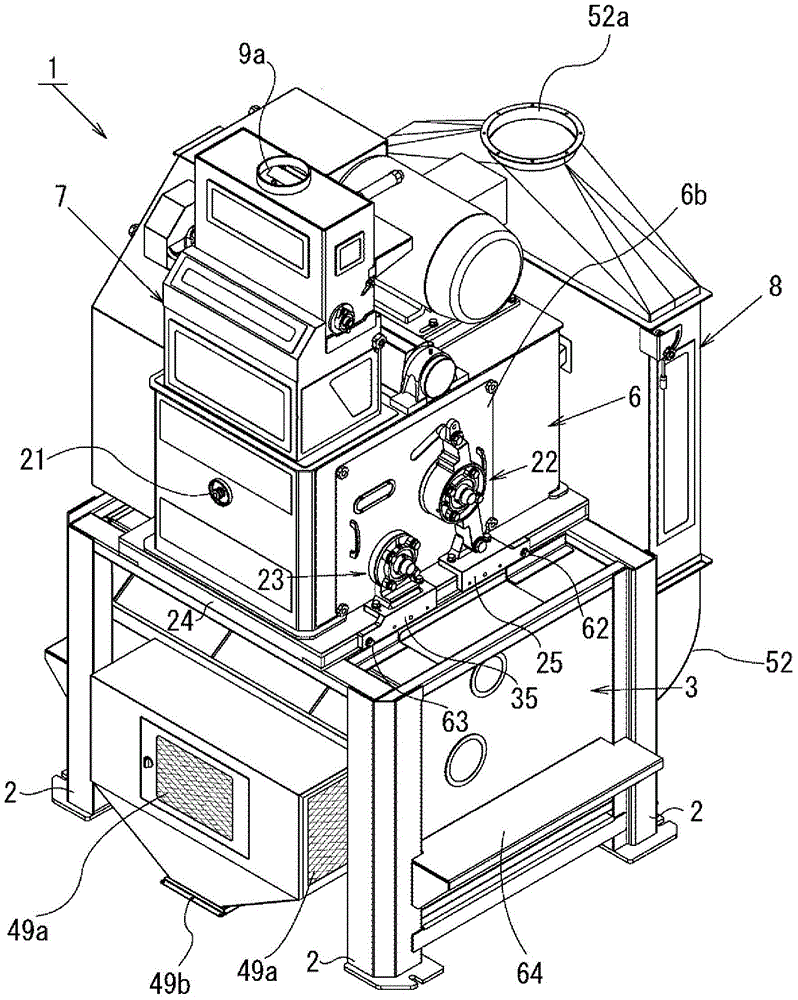

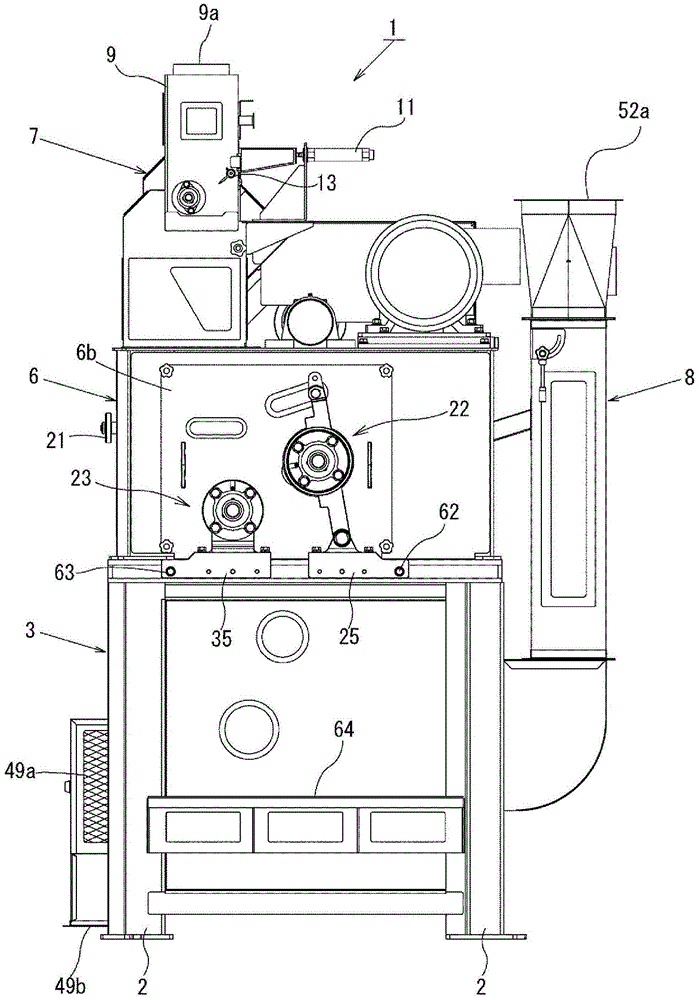

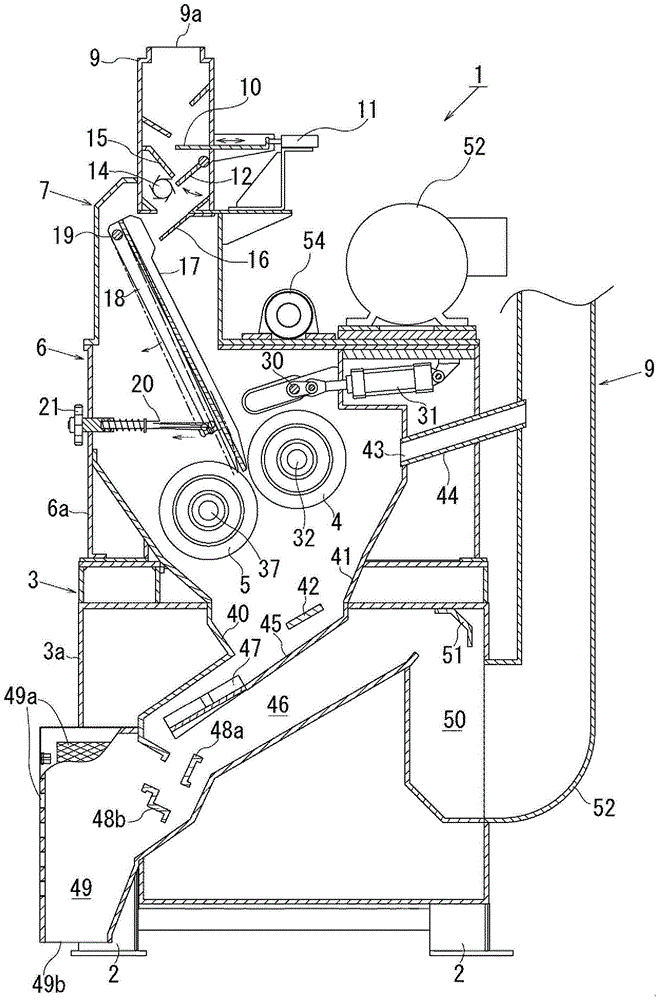

[0035] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a perspective view showing the whole of the rice huller of the present invention, figure 2 is the front view of the huller, image 3 It is a schematic longitudinal sectional view showing the internal structure of the rice huller.

[0036] (The overall structure of the huller)

[0037] Such as Figure 1 to Figure 3 As shown, the main part of the rice huller 1 is composed of the following parts: the winnowing part 3, which is located in the winnowing channel inside the frame supported by a plurality of pillars 2, and the winnowing of the hulled rice is carried out; the hulling part 6 , it is loaded on the top of the winnowing part 3, and consists of a pair of rubber rollers 4, 5, the rubber roller on one side is supported on the fixed bearing, and the rubber roller on the other side is supported at a distance relative to the fixed bearing. On the moving bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com