Screen printing device and screen printing method

A technology of screen printing machine and paste, which is applied in the direction of screen printing machine, printing, printing machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

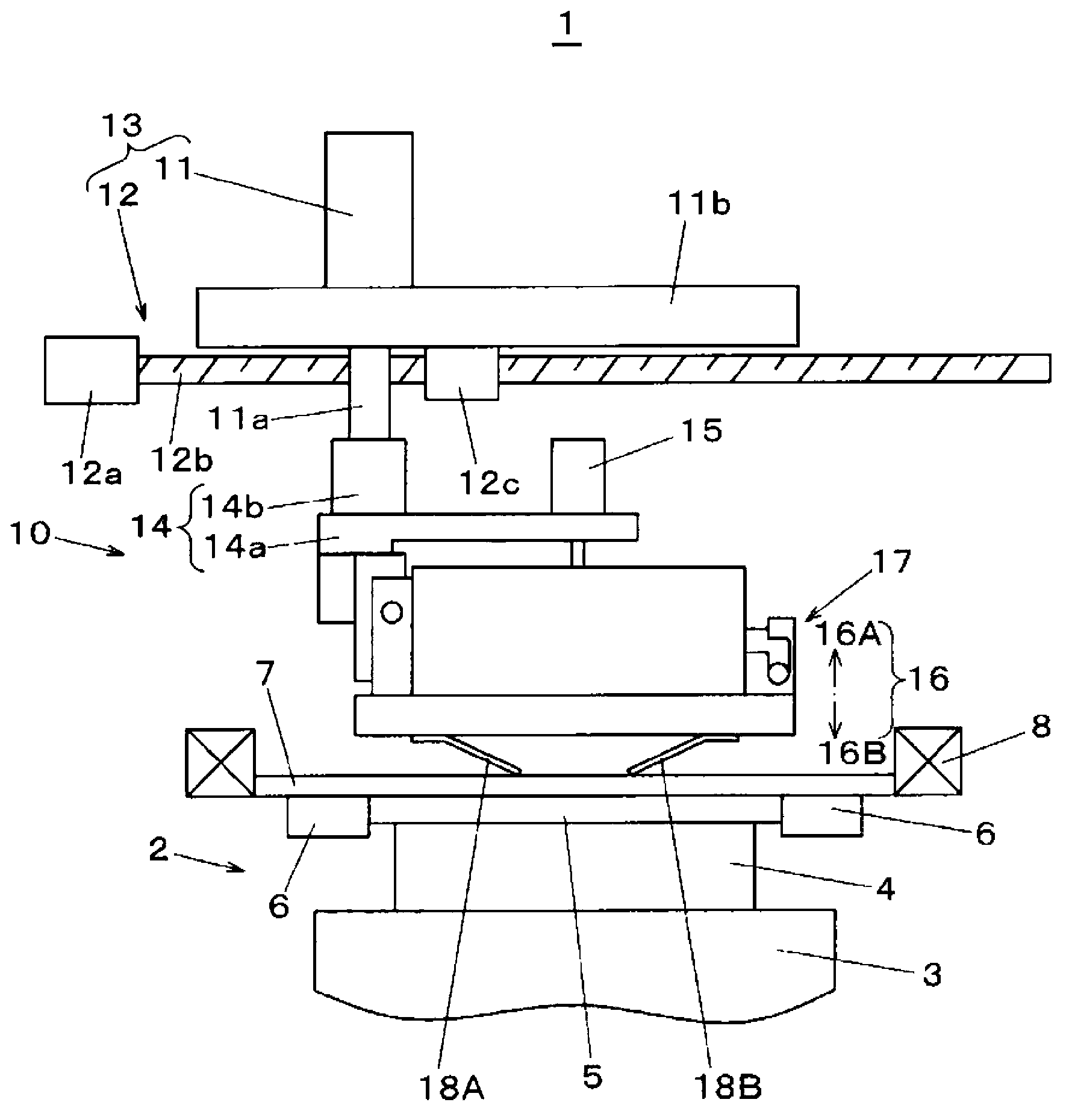

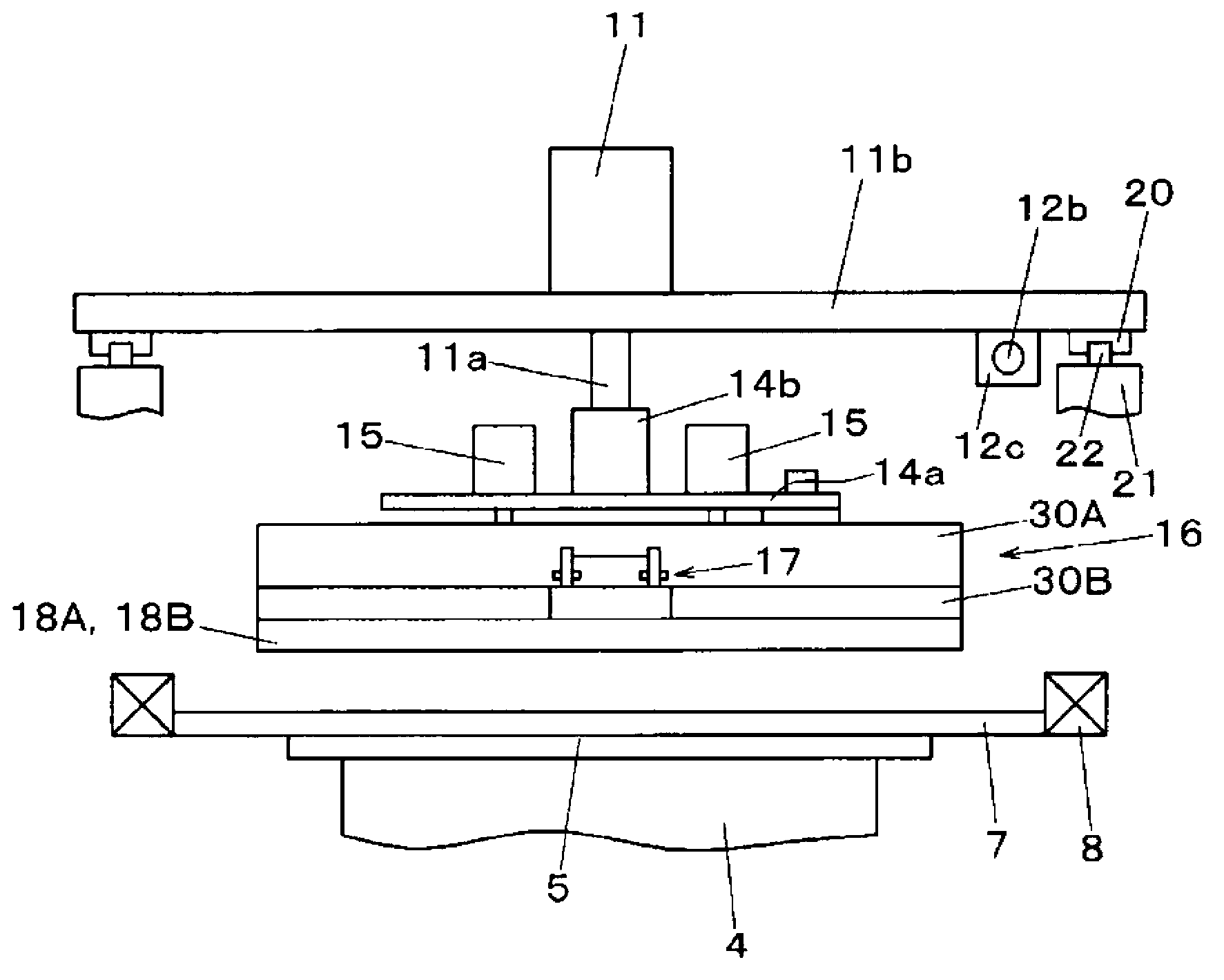

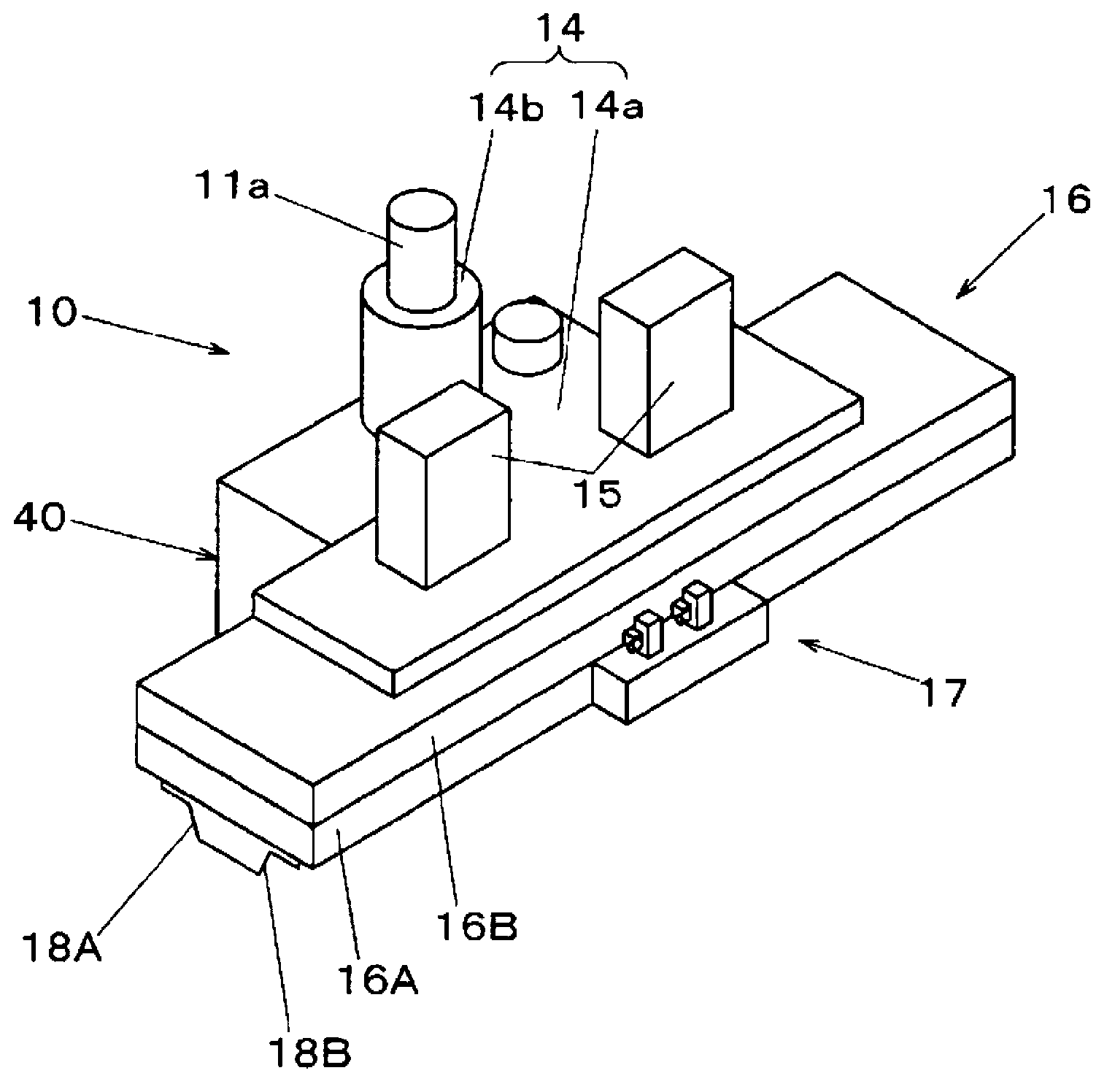

[0024] The embodiments of the present invention will now be described with reference to the drawings. First refer to figure 1 , 2 And 3 describe the entire configuration of the screen printer 1. The screen printer 1 has the following functions. That is, the squeegee head 10 slides on the mask plate 7 under the action of the head drive mechanism 13, so that the substrate 5 is printed with the solder paste 9 as an electronic component bonding paste through the pattern hole 7a of the mask plate 7. in figure 1 with 2 Among them, the screen printer 1 is configured such that the mask plate 7 held by the mask holder 8 is set at a raised position above the substrate positioning portion 2 and the screen printing mechanism is also located above the mask plate 7.

[0025] The structure of the substrate positioning portion 2 is described. The lower substrate receiver 4 is provided on the upper surface of the moving table 3 so as to be able to perform ascending and descending actions. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com