Welding wire feeding device

A technology of feeding device and welding wire, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as troublesome replacement operations, and achieve the effect of simplifying replacement operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0073] Embodiments of the invention will be described based on examples with reference to the drawings.

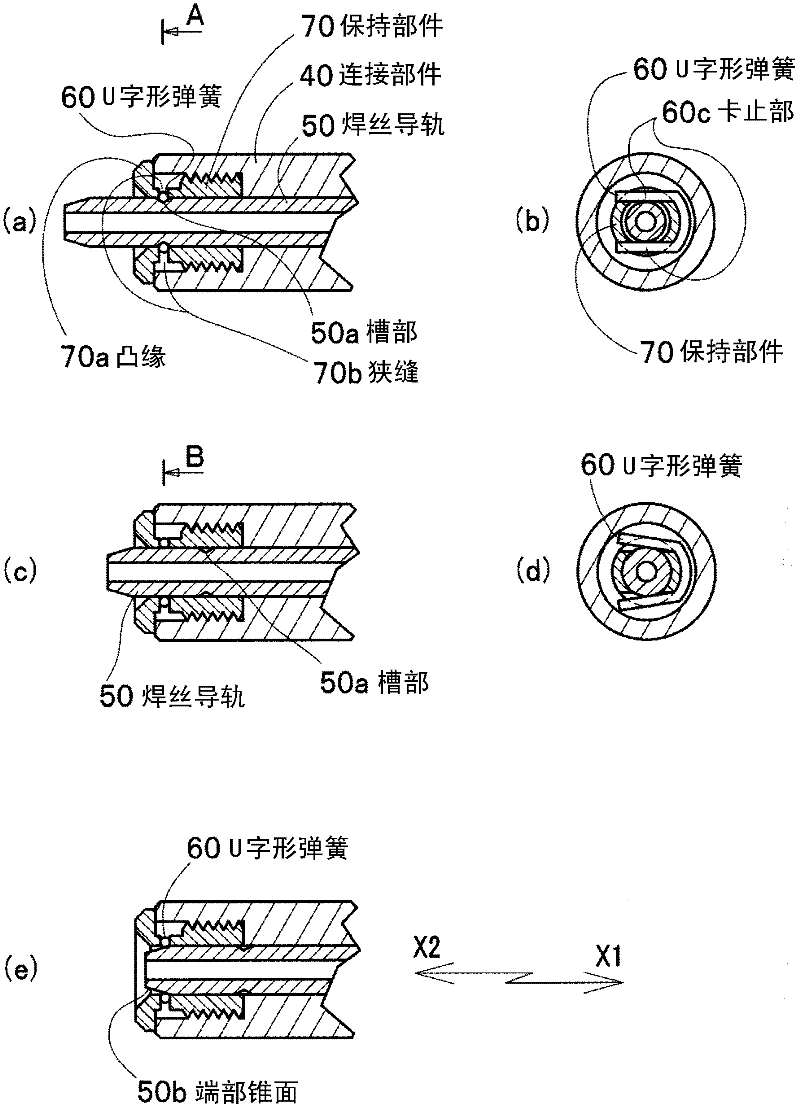

[0074] figure 1 (a) is a partial sectional view of the wire feeding device according to Embodiment 1 of the present invention. figure 1 (b) is figure 1 (a) A cross-sectional view. figure 1 (c), (d), and (e) are diagrams showing the operating state of Embodiment 1 of the present invention, figure 1 (d) is figure 1 (c) B-direction cross-sectional view.

[0075] The difference between the wire guide 50 of the wire feeder according to Embodiment 1 of the present invention and the wire guide 50 of the conventional wire feeder is as follows.

[0076] exist figure 1 In (a), (c), and (e), it is assumed that the wire feeding direction is the X1 direction, and the opposite direction is the X2 direction. An internal thread is provided on the inner diameter of the end portion of the connecting member 40 on the feeding drum 10 side (X2 direction). The holding member 70 i...

Embodiment approach 2

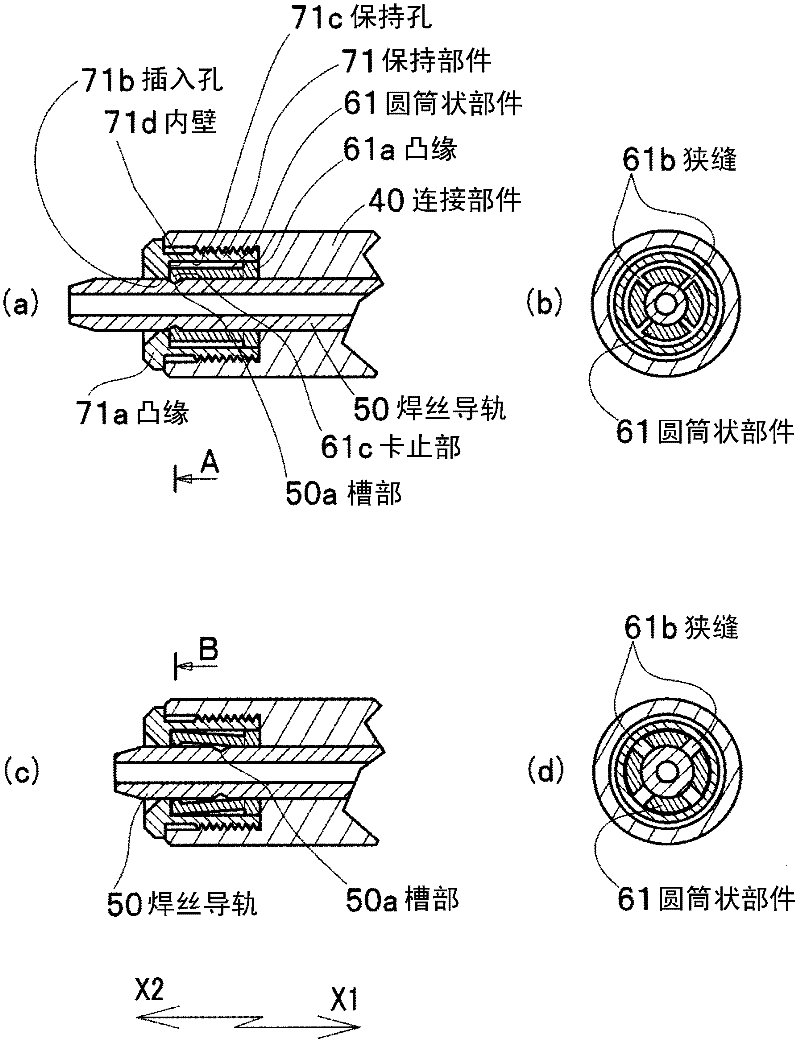

[0086] figure 2 (a) is a partial cross-sectional view of a welding wire feeding device according to Embodiment 2 of the present invention, figure 2 (b) is figure 2 (a) A cross-sectional view. figure 2 (c), (d) are figures which show the operation state of Embodiment 2 of this invention, figure 2 (d) is figure 2 (c) B-direction cross-sectional view. exist figure 2 In (a) and (c), it is assumed that the wire feeding direction is the X1 direction, and the opposite direction is the X2 direction. An internal thread is provided on the inner diameter of the end portion of the connecting member 40 on the feeding drum 10 side (X2 direction). The holding member 71 is a cylindrical member, and an external thread screwed into the internal thread of the connecting member 40 is provided on the outer peripheral portion of the front end (X1 direction), and a flange 71a is provided at the other end (X2 direction), and the end surface of the flange 71a is It abuts against the end ...

Embodiment approach 3

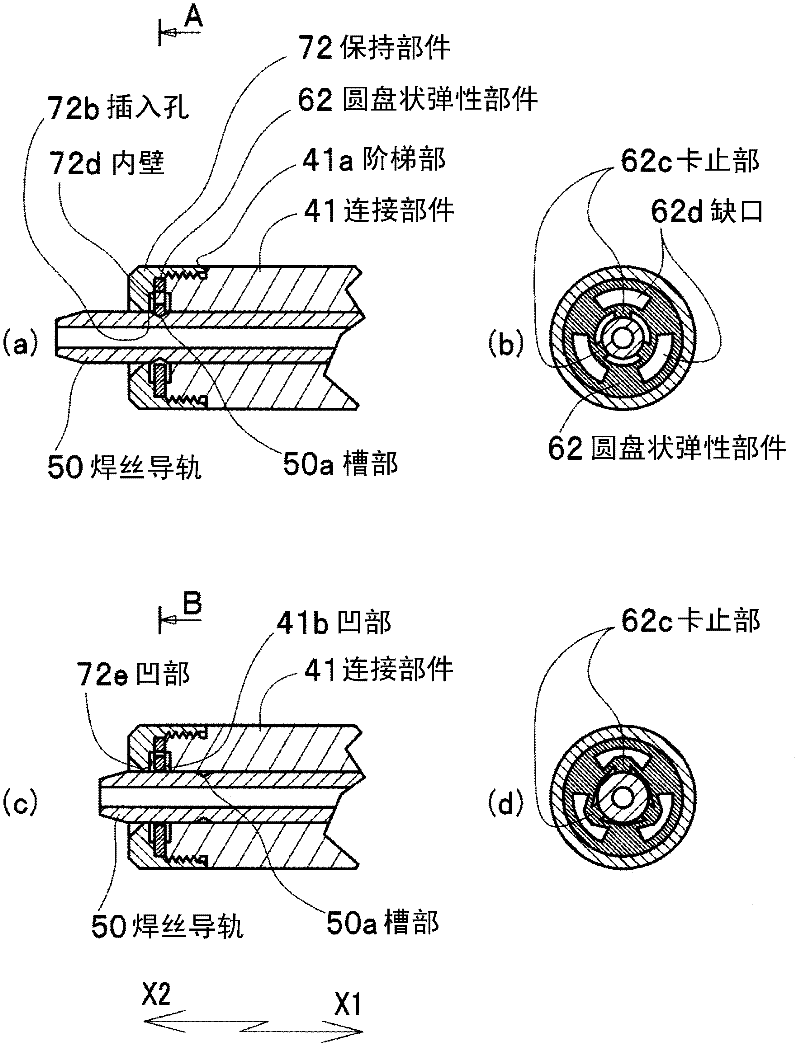

[0093] image 3 (a) is a partial cross-sectional view of a welding wire feeding device according to Embodiment 3 of the present invention, image 3 (b) is image 3 (a) A cross-sectional view. image 3 (c), (d) are figures which show the operation state of Embodiment 3 of this invention, image 3 (d) is image 3 (c) B-direction cross-sectional view. exist image 3 In (a) and (c), it is assumed that the wire feeding direction is the X1 direction, and the opposite direction is the X2 direction.

[0094] The outer diameter of the end portion of the connecting member 41 on the feeding drum 10 side (X2 direction) is provided with an external thread, and a stepped portion 41a is formed from the end of the external thread to the outer peripheral portion. The holding member 72 is a cylindrical member, and an internal thread screwed into the external thread of the connection member 41 is provided on the inner diameter portion of the front end (X1 direction), and the front end (X1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com