Film stretching loading unit with position locking function

A loading unit and thin film technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as difficulty in placing on the observation platform, large overall size of the equipment, cumbersome and time-consuming operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

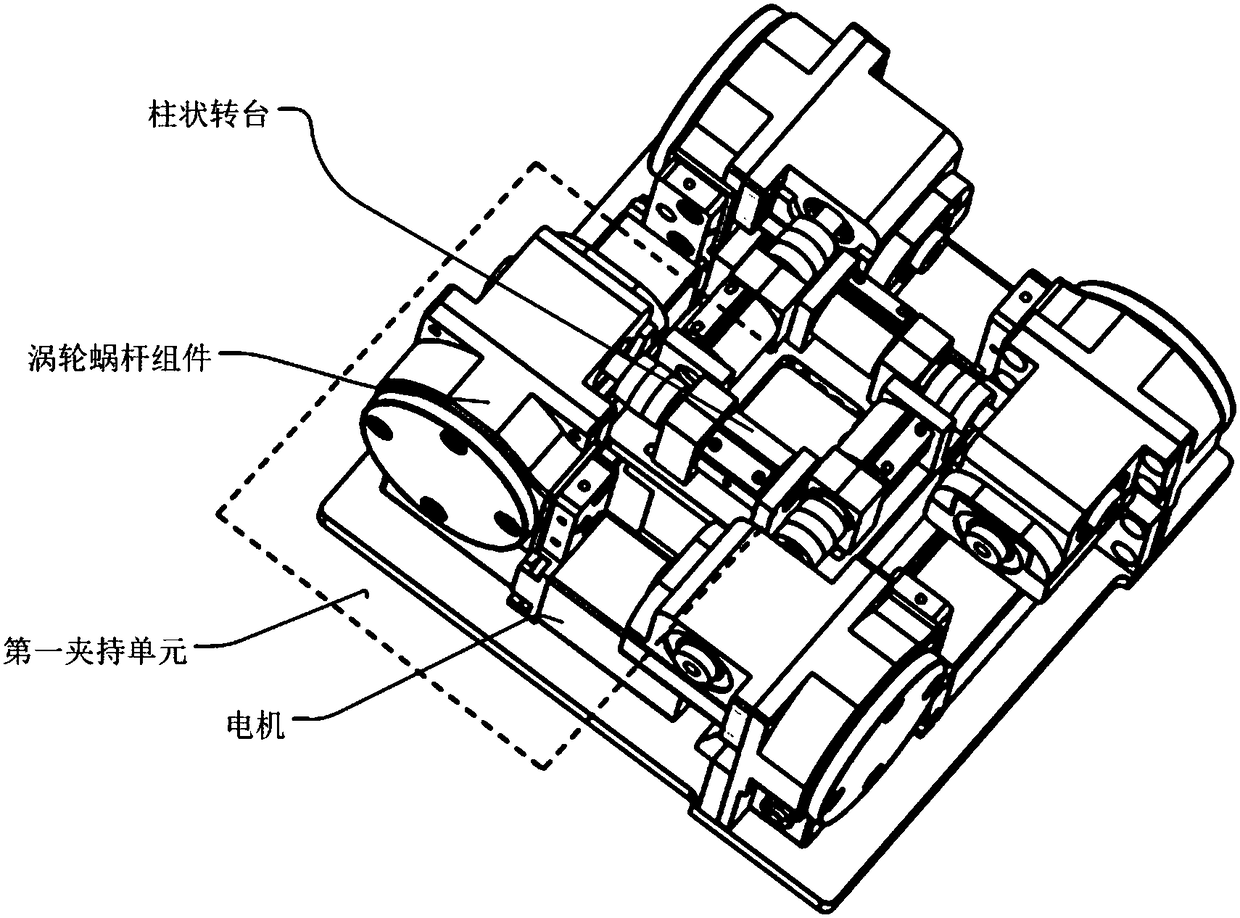

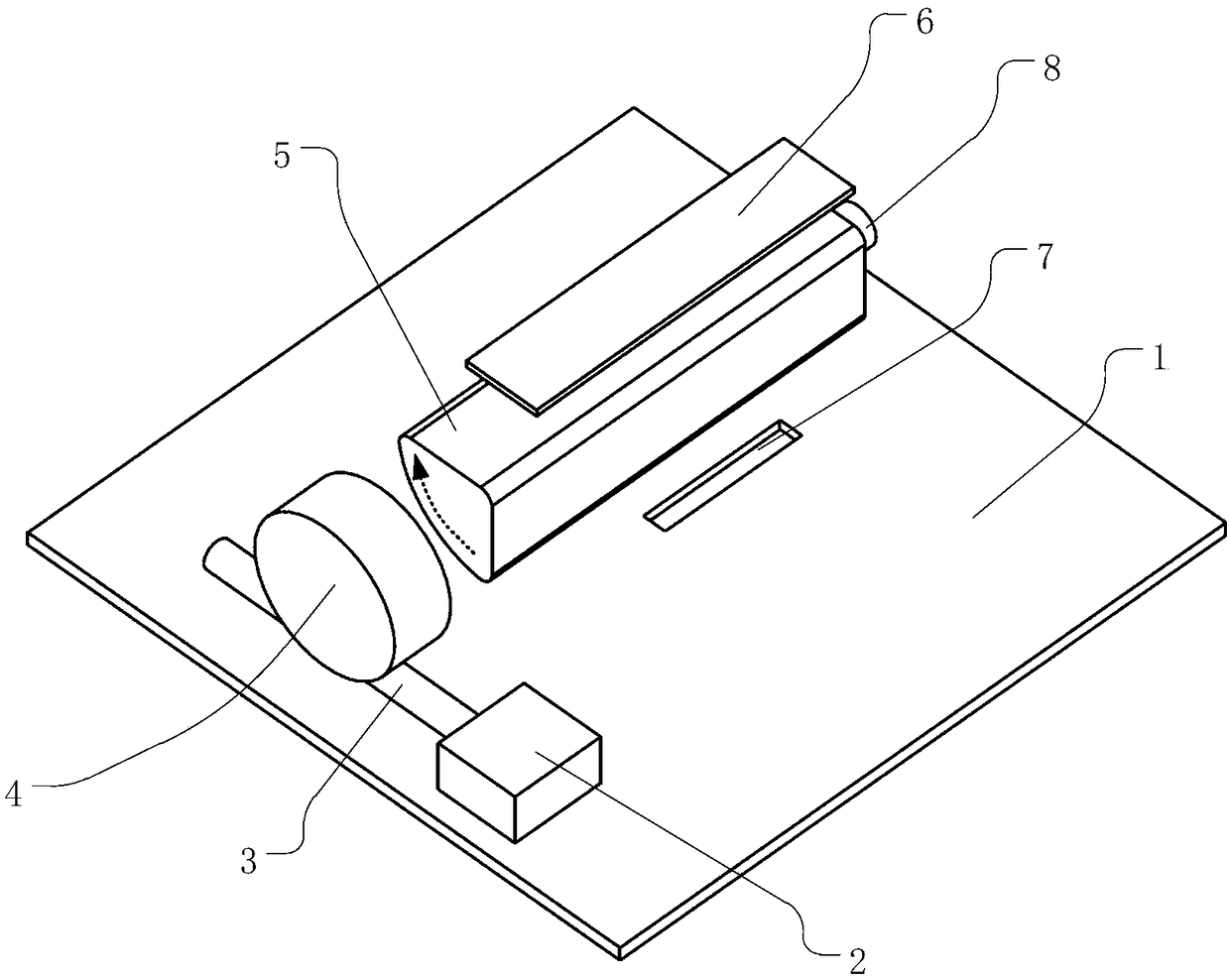

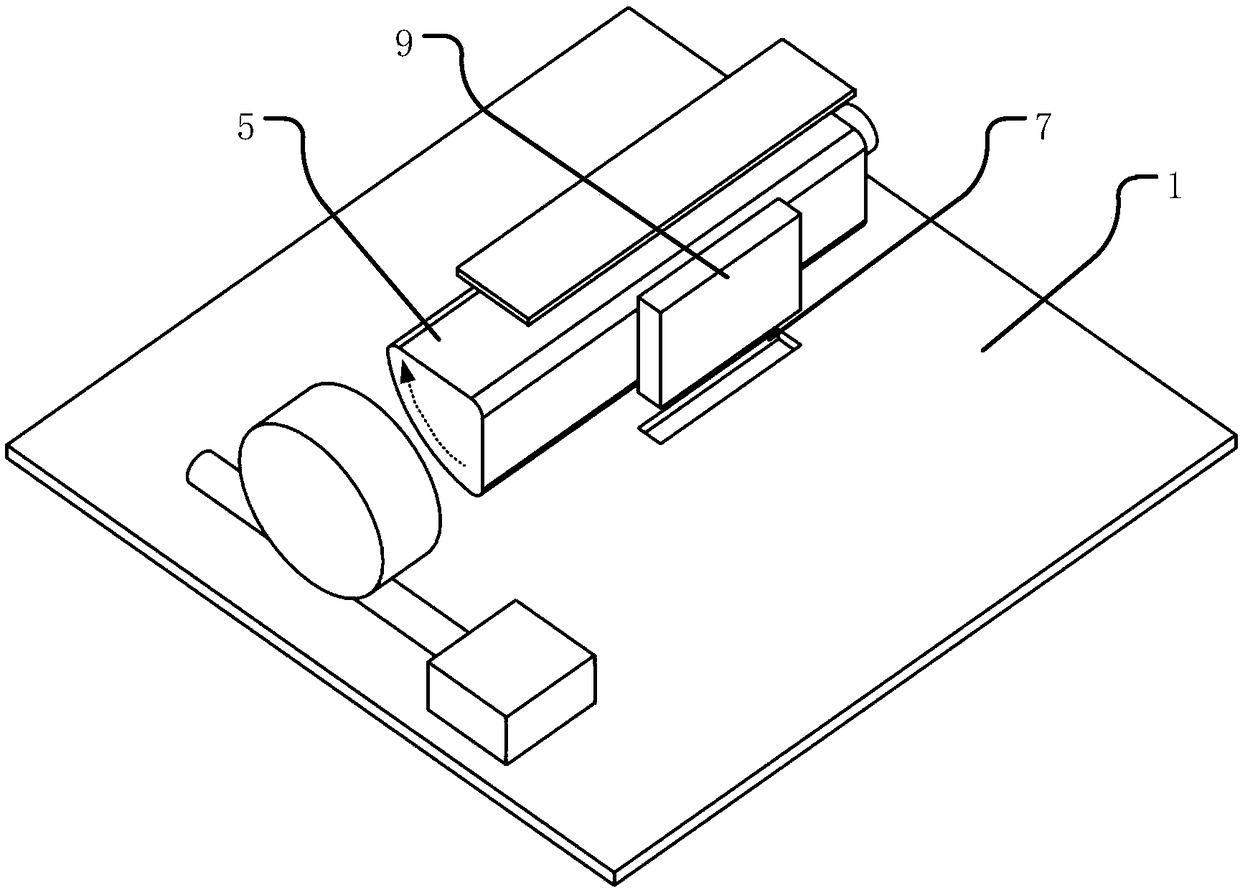

[0019] Such as figure 2 As shown, the present invention proposes a film stretching and loading unit with a position locking function, including a substrate 1, a motor 2, a worm 3, a turbine 4, a loading turntable 5, a fastening clip 6, a positioning member 9, and the motor 2 is fixed Set on the substrate 1, the output shaft of the motor 2 is connected to the worm 3 and drives the worm 3 to rotate, and the worm 3 is installed in cooperation with the turbine 4 and drives the turbine 4 to rotate;

[0020] One end of the turbine is rotatably arranged on the base plate 1, and the other end has a groove, the vertical section of the groove is the same shape as the vertical section of the loading turntable 5, and one end of the loading turntable 5 can be inserted into the groove so that the turbine 4 drives The loading turntable 5 rotates, and the other end of the loading turntable 5 is provided with a cylindrical arm 8 so that the loading turntable 5 is rotatably arranged on the bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com