Hydraulic pump jack sytem for reciprocating oil well sucker rods

a technology of hydraulic pump and sucker rod, which is applied in the direction of piston pump, positive displacement liquid engine, borehole/well accessories, etc., can solve the problem that the walking beam pumping system cannot run at a slow enough rate, and achieve the effect of more efficient actuation of the bottom hole pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It is to be understood that the invention that is now to be described is not limited in its application to the details of the construction and arrangement of the parts illustrated in the accompanying drawings. The invention is capable of other embodiments and of being practiced or carried out in a variety of ways. The phraseology and terminology employed herein are for purposes of description and not limitation.

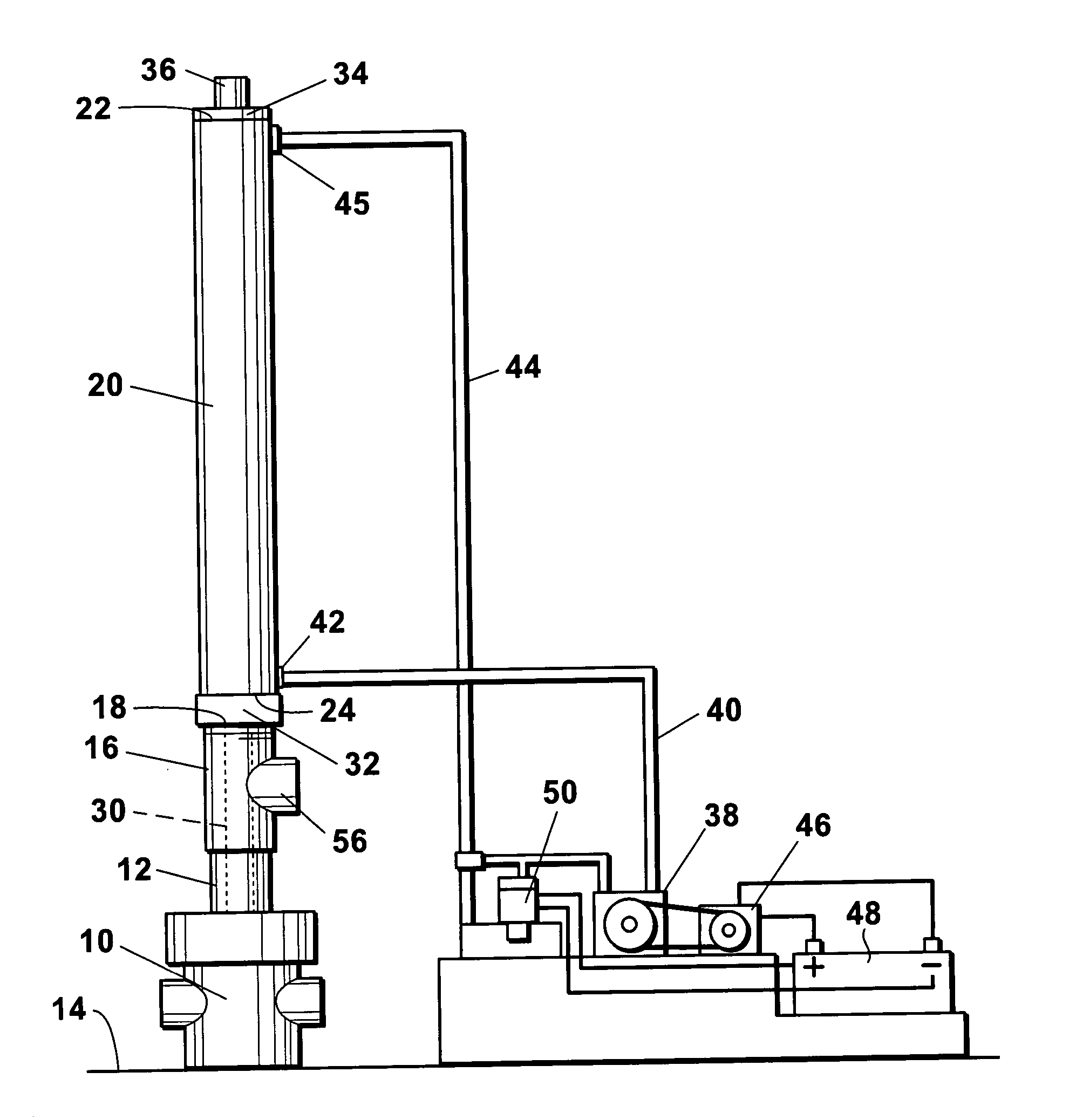

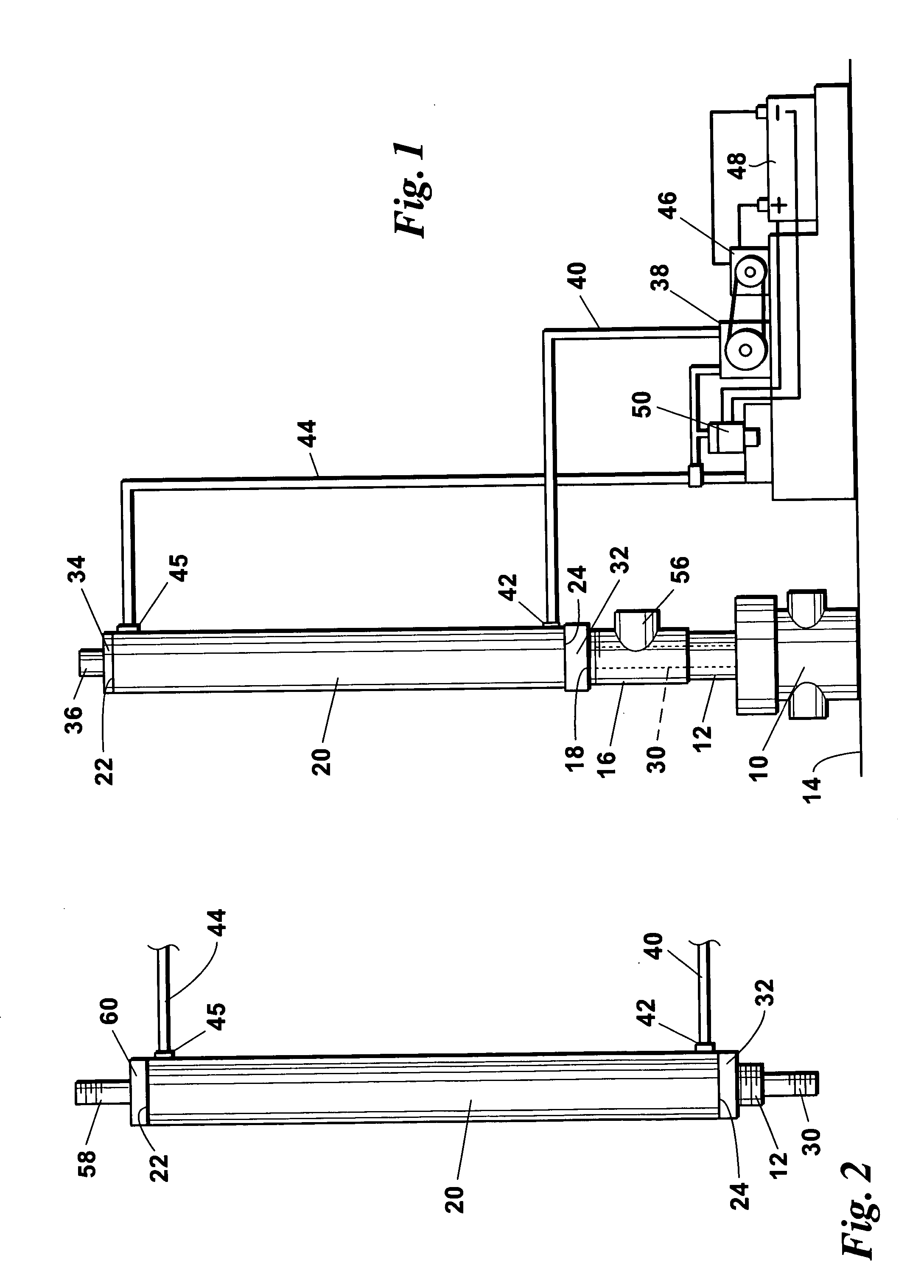

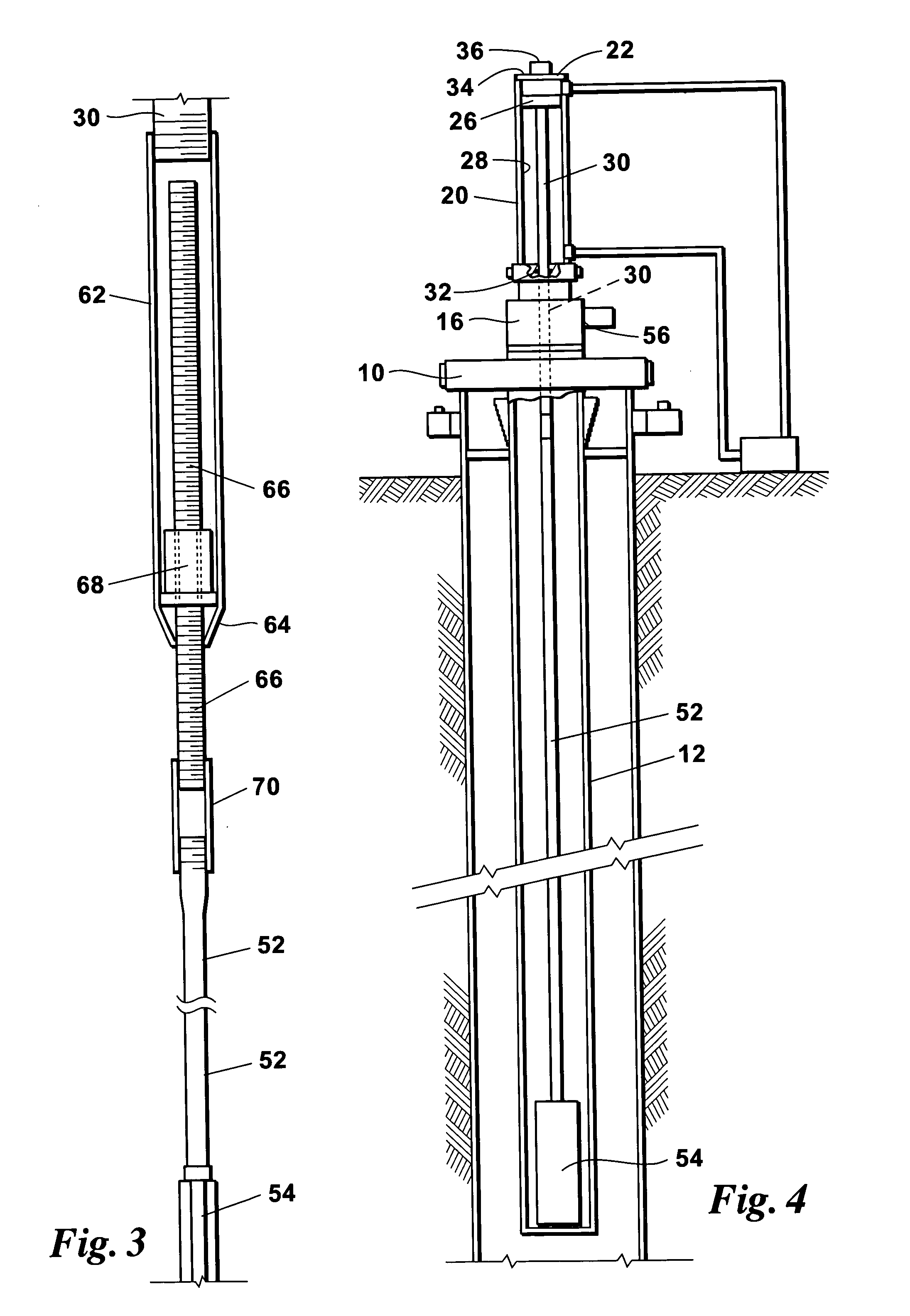

[0021] Elements shown by the drawings are identified by the following numbers:

[0022]10 wellhead

[0023]12 tubing

[0024]14 earth's surface

[0025]16 Tee fitting

[0026]18 top of 16

[0027]20 hydraulic cylinder

[0028]22 top end

[0029]24 bottom end

[0030]26 piston

[0031]28 internal cylinder wall

[0032]30 downward extending piston rod

[0033]32 seal member

[0034]34 closure member

[0035]36 air vent

[0036]38 hydraulic fluid pump

[0037]40 pipe

[0038]42 inlet opening

[0039]44 return pipe

[0040]46 prime mover

[0041]48 battery

[0042]50 hydraulic controls

[0043]52 string of sucker r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com