Sucker-rod pump oil pumping machine oil pumping control method and its system

A control method and pumping unit technology, applied in the general control system, control/regulation system, pump control, etc., can solve problems such as limited effect, poor real-time performance, adjustment of pumping unit stroke parameters, etc., to save electric energy, The effect of improving pumping productivity and reducing equipment maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

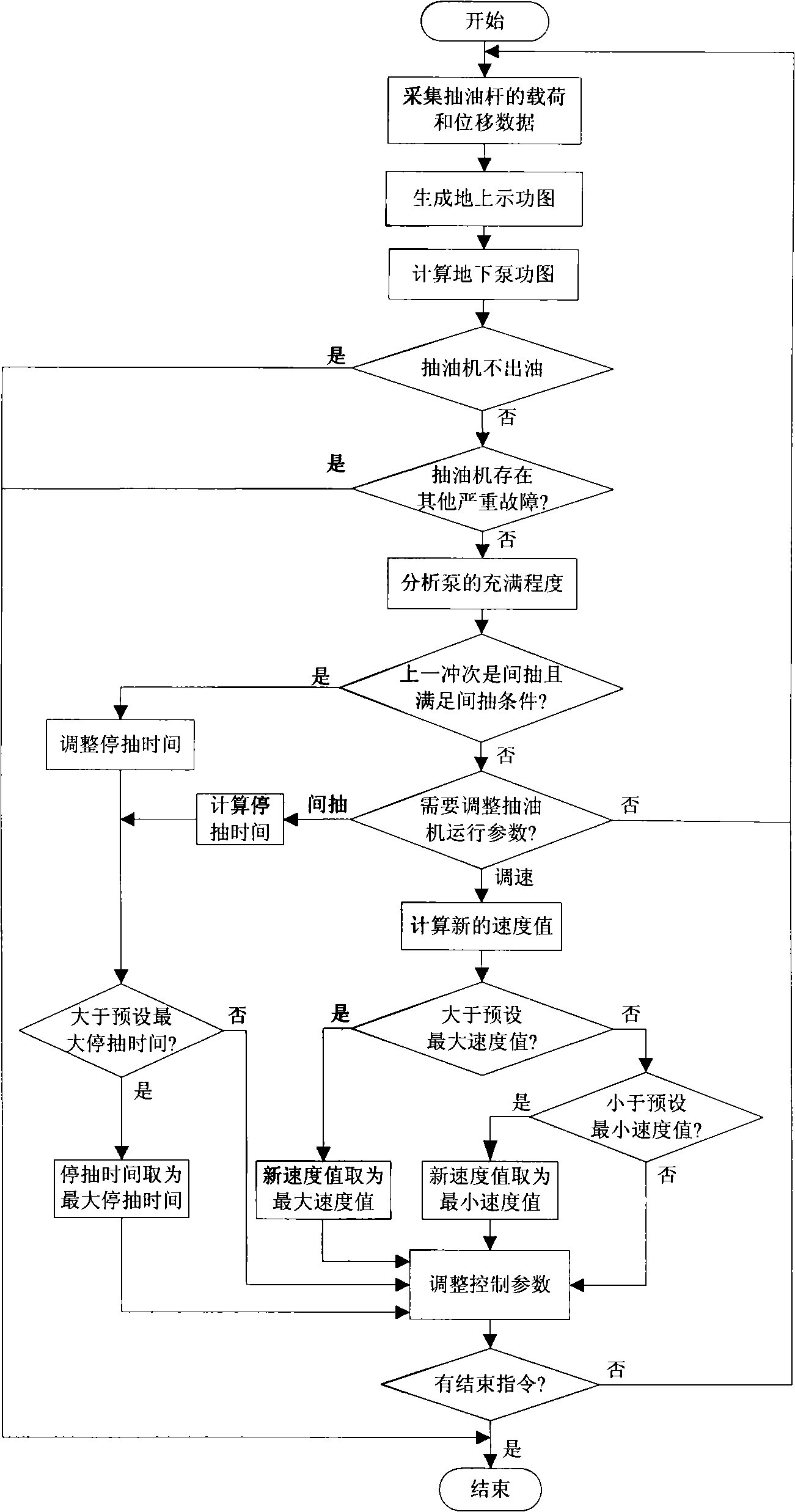

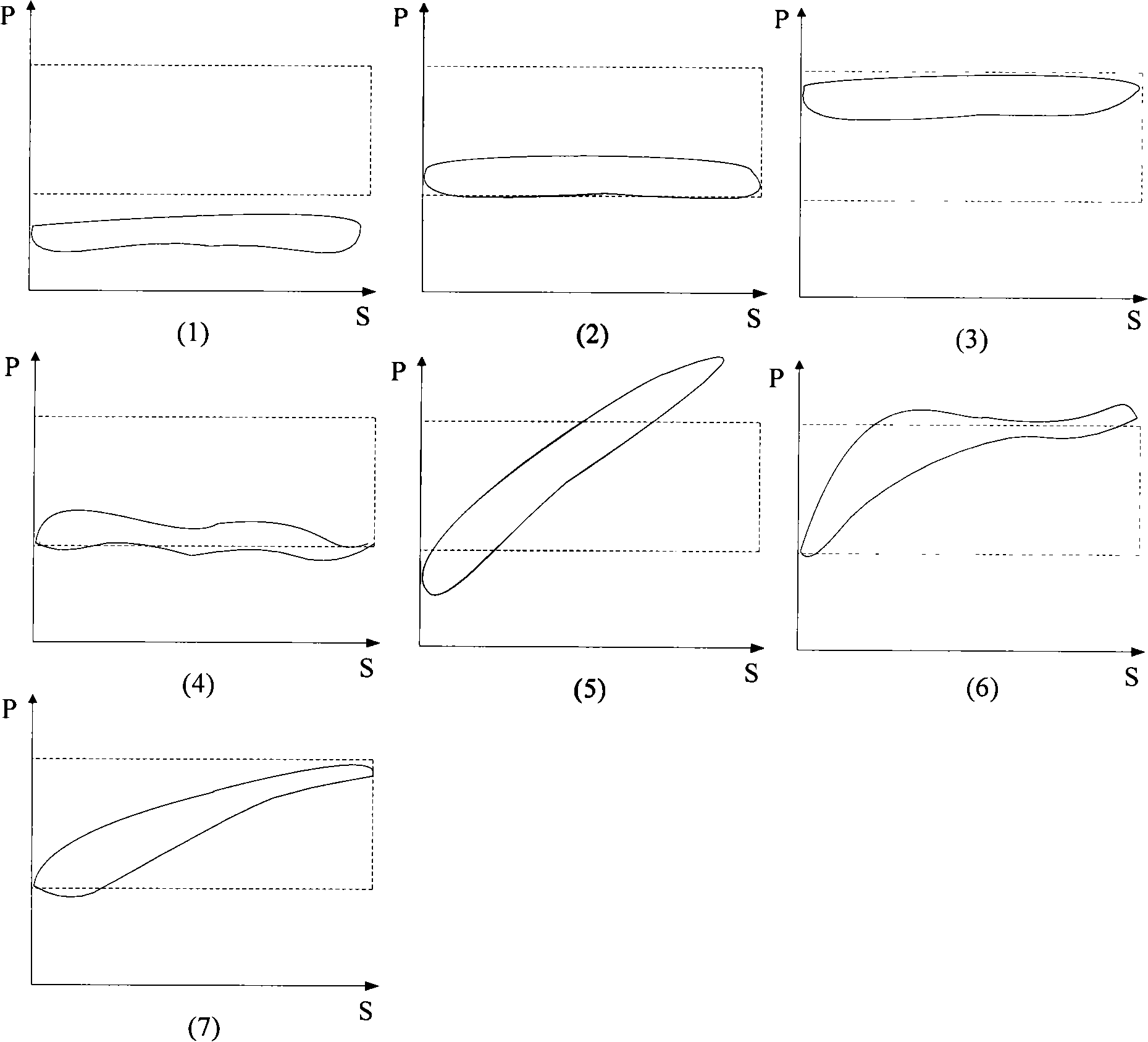

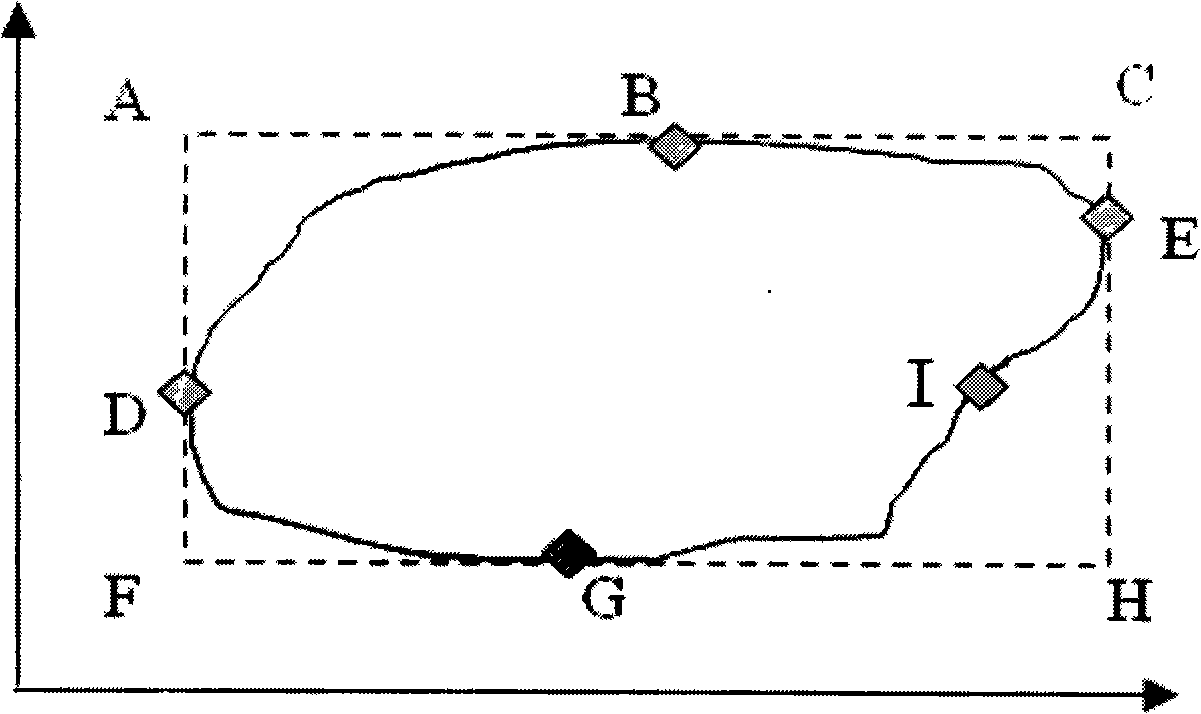

Method used

Image

Examples

example

[0123] See attached Figure 4 , the rod pump pumping unit controller adopts ARM embedded processor 1 as the core, and the software platform is uCLinux operating system and GUI. One end of the input control circuit 2 of the controller is connected to the input device 3, and one end is connected to the processor 1; the TFT liquid crystal screen 5 is connected to the processor 1 through the liquid crystal screen control circuit 4; the wireless communication module 7 is connected to the level conversion circuit 6 through a serial port, 6 is connected to UART0 of processor 1; one end of motor driver 8 is connected to rod pumping unit 12, and one end is connected to level conversion circuit 6 through a serial port, and 6 is connected to UART1 of processor 1; The load sensor 10,10 is connected to the signal conditioning circuit 9,9 is connected to one ADC converter of the processor 1; One ADC converter; IDE hard disk control circuit 13, storage circuit including PSRAM, NANDFLASH and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com