Large and middle wind turbine digital intelligent hydraulic brake system

A hydraulic braking and digital technology, applied in the field of digital intelligent hydraulic braking system of large and medium wind turbines, can solve the problems of affecting the stability and reliability of wind turbines, fast wear of brake pads, large mechanical vibration, etc., and achieves a simple structure. , Reliable work, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

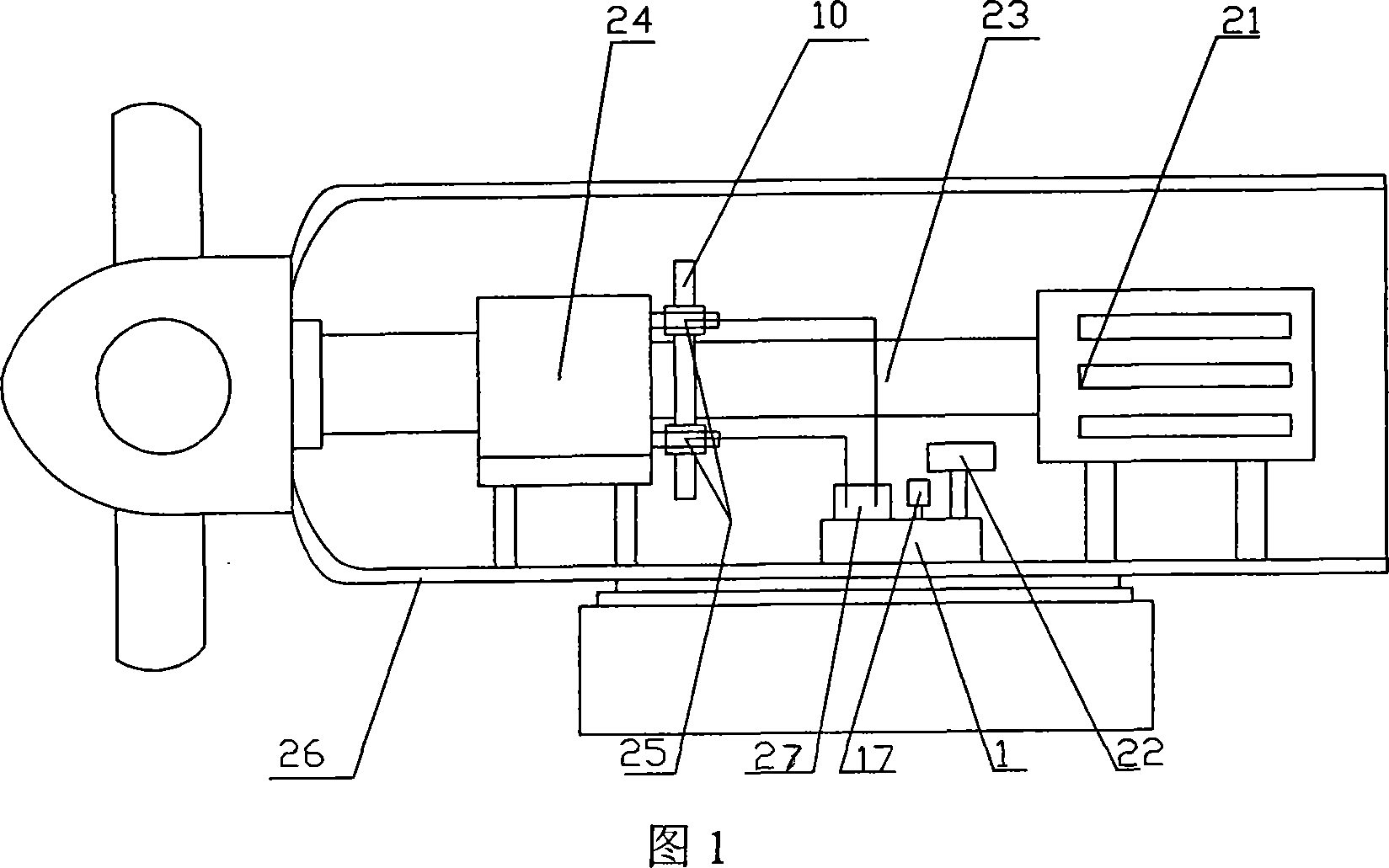

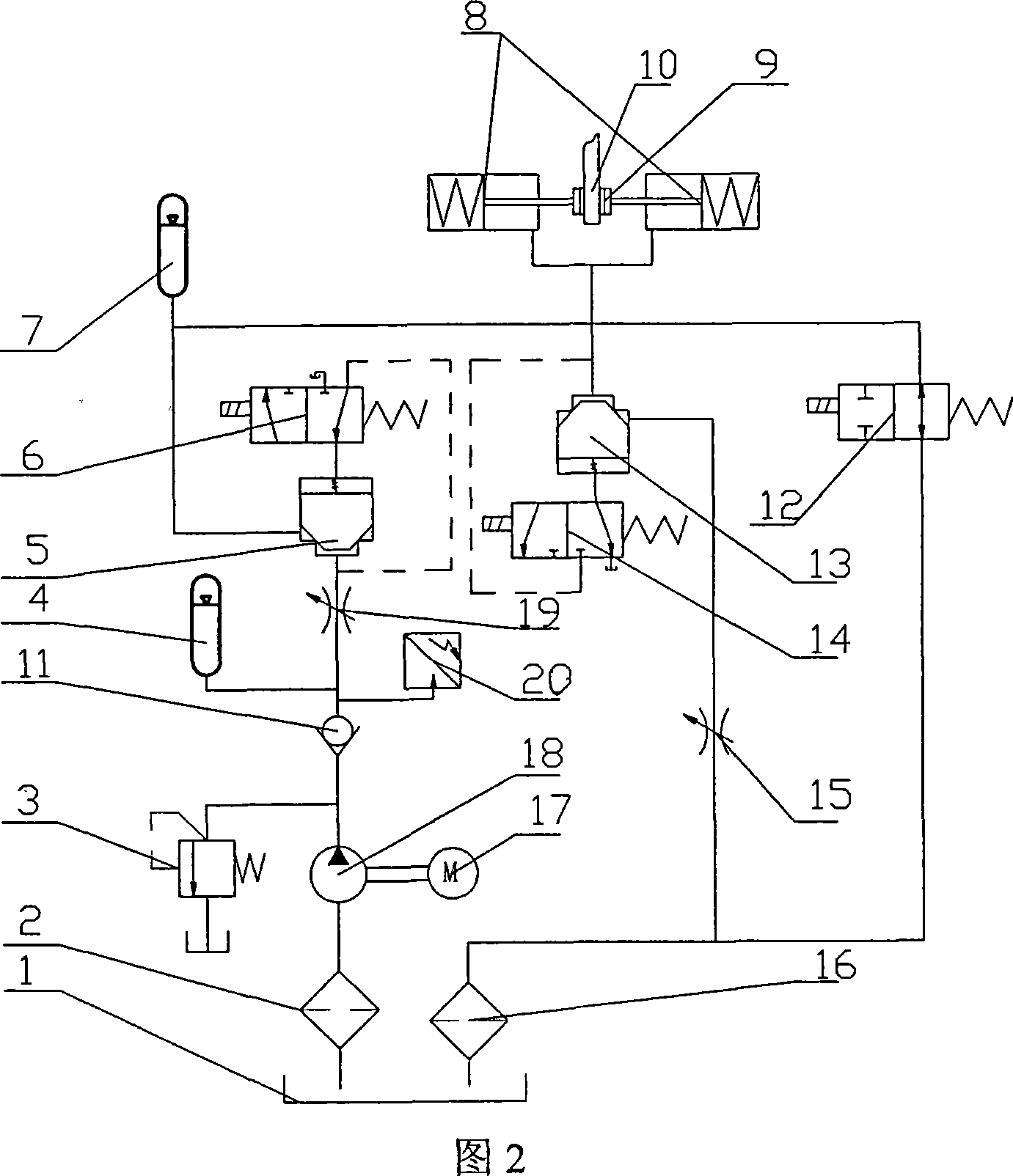

[0017] As shown in Figure 2, the present invention comprises two accumulators 4,7, two throttle valves 15,19, two high-speed on-off valves 6,14, two cartridge valves 5,13, on-off valve 12, two Above the sleeve, brake pads 9 are installed at the end of the rod cavity, two hydraulic cylinders 8, brake pads 9, pressure relay 20 and oil supply system are arranged in a group, and the output terminal of the oil supply system is connected to one-way The input end of the valve 11 and the output end of the check valve 11 are divided into three routes, the first route is connected to the first accumulator 4, the second route is connected to the pressure relay 20, and the third route is connected to the first accumulator 4 through the first throttle valve 19. The input end of the cartridge valve 5 and the output end of the first cartridge valve 5 are connected to the second accumulator 7; the rod chambers of all the hydraulic cylinders 8 are divided into three routes through the bus, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com