Machine oil pump of I.C. engine

A technology for oil pumps and internal combustion engines, applied to machines/engines, liquid fuel engines, pumps, etc., can solve problems such as oil leakage through mounting bolt holes, and achieve the effect of preventing oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

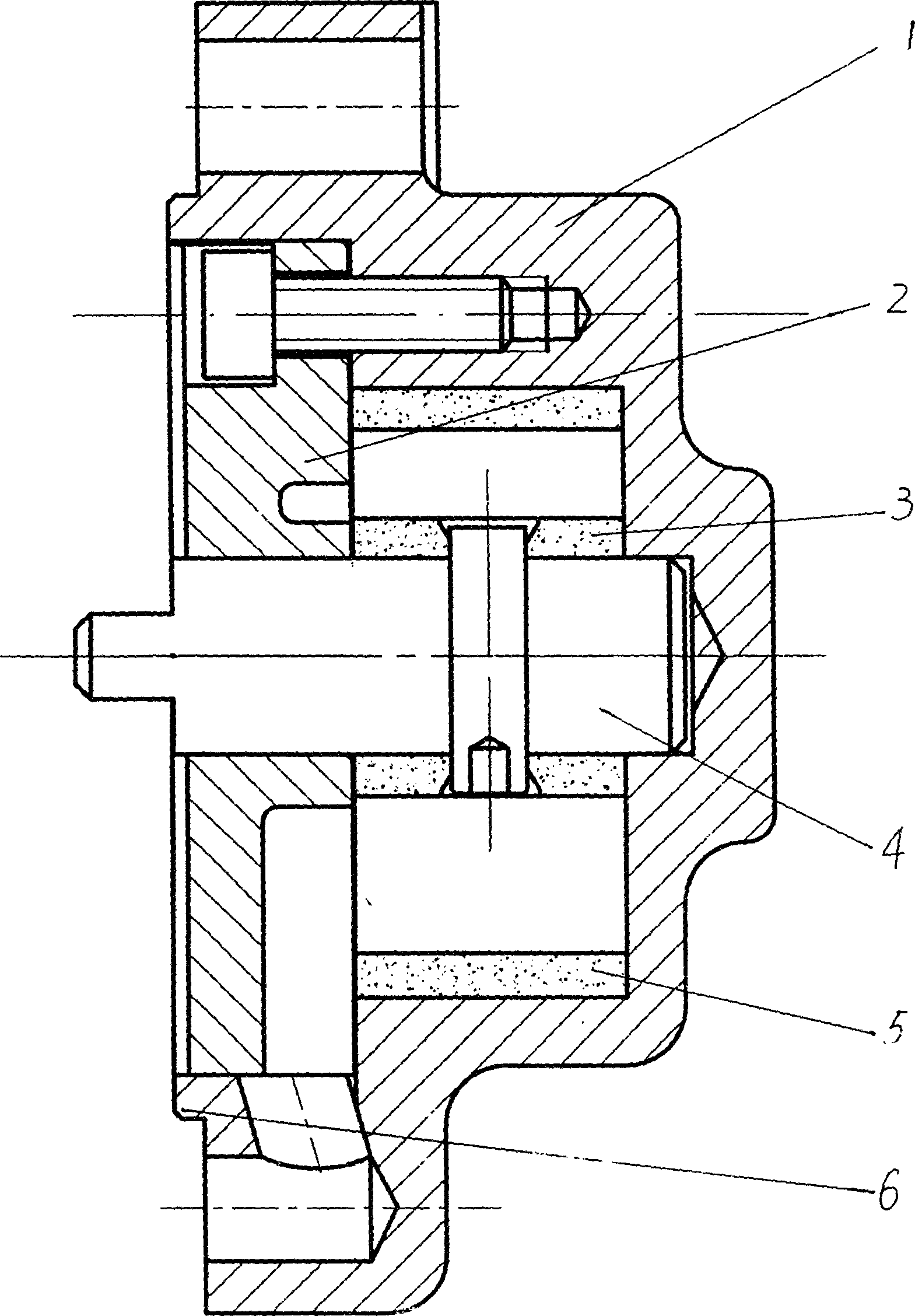

[0008] As shown in the figure, an internal combustion engine oil pump is composed of a pump casing (1), an inner rotor (3), an outer rotor (5), a shaft (4) and a flow plate (2). The inner and outer rotors (3, 5) The tooth profile is cycloid, the inner rotor (3) is located in the outer rotor (5), and is fixed on the shaft (4), there is a certain eccentricity between the inner and outer rotors (3, 5), and it is installed in the pump casing Inside (1), the pump casing (1) is in the shape of a concave disc, and there is a positioning boss (6) at the opening end of the pump casing (1), and the distribution plate (2) is embedded and fixed at the opening of the pump casing (1) , the surface of the distribution plate (2) is slightly lower than the surface of the boss (6), and one end of the shaft (4) is sleeved in the central hole of the distribution plate (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com