Motorcycle engine

An engine and motorcycle technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problem that lubricating oil can not meet the needs of engine lubrication and cooling, affect the reliability and service life of the engine, and increase the probability of the crankshaft being locked and other problems, to achieve the effect of eliminating excessive consumption of lubricating oil, compact structure, and avoiding the phenomenon of oil stringing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

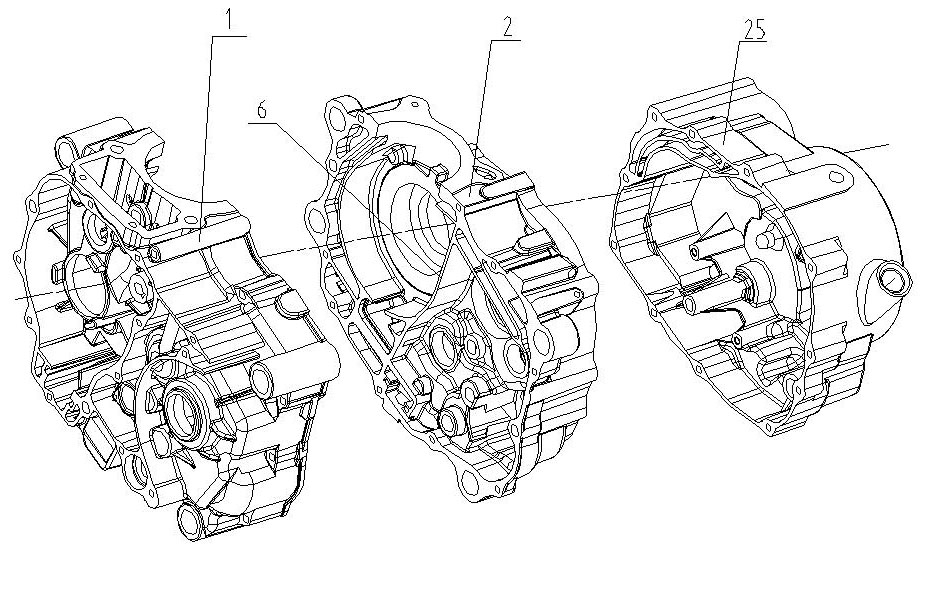

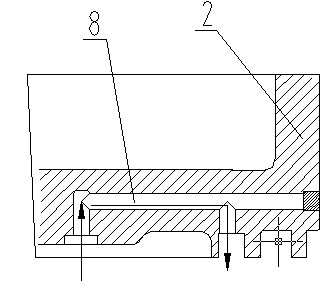

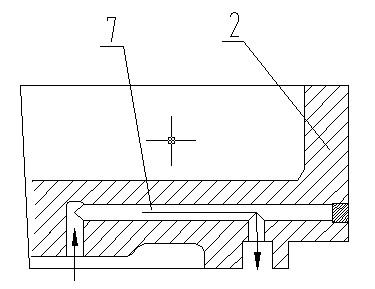

[0024] like Figure 1 to Figure 6 As shown, the motorcycle engine of the present invention has a left case body 1, a right case body 2 and a right cover 25, and the left case body 1 and the right case body 2 are butted together to form a crank case body. A first sealing rib 5 is provided between the power chamber 3 and the transmission chamber 4 of the left case 1, a second sealing rib 6 is provided between the power chamber 3 and the transmission chamber 4 of the right case 2, and the left case 1 and the right After the case body 2 and the box face are butted and assembled, the first sealing rib 5 and the second sealing rib 6 are joined together as an oil separation belt to completely separate the power chamber 3 and the transmission chamber 4 of the engine. The box body 2 is formed with mutually independent power chamber lubricating oil passage 7 and transmission cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com